Aqueous, alkaline, cyanide-free bath for the galvanic deposition of zinc alloy coatings

a zinc alloy coating and cyanide-free technology, applied in the field of aqueous alkaline galvanic baths, can solve the problems of strong corrosive effect of electrolyte on the electroplating equipment, uniform layer or uniform brightness is often not achieved across the entire range of current densities, and strong hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

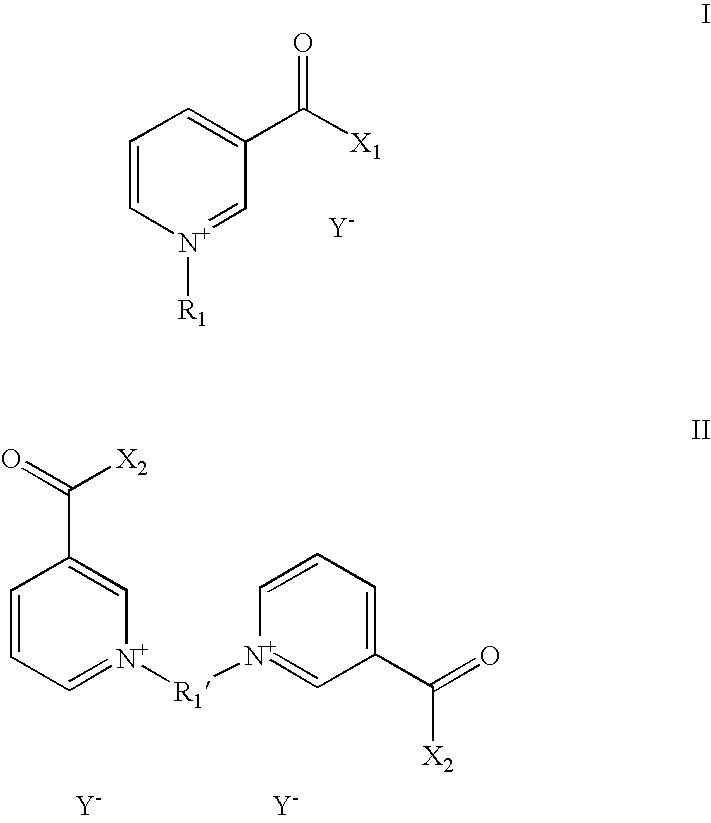

Synthesis of 1-(4′-methoxy-benzyl)-3-carbamoyl-pyridinium-chloride

[0063]In a 100 ml round-bottom flask with reflux condenser, 60 ml of water, 9.2 g of nicotinic acid amide (98%) (0.0738 mol), 11.68 g of 4-methoxybenzylchloride (99%) (0.07378 mol) are heated under reflux for 24 hours. After completion of the reaction, the water is removed in vacuo and the residue is taken up in 200 ml of ethanol and heated under reflux for another hour. The reaction mixture is then cooled to 4° C. and the white solid obtained is removed by filtration and dried in vacuo. This yielded 16.92 g of a white solid (82.26% of the theoretical yield).

preparation example 2

Synthesis of 1-(4′-chloro-benzyl)-3-carbamoyl-pyridinium-chloride

[0064]In a 100 ml round-bottom flask with reflux condenser, 60 ml of ethanol, 10 g of nicotinic acid amide (98%) (0.0802 mol), 13.05 g of 4-chloro-benzylchloride (99%) (0.0802 mol) are heated under reflux for 24 hours. After completion of the reaction, the solid residue is heated in an ethanol / methanol mixture for another 15 minutes and then cooled to 4° C. The solid obtained is removed by filtration and dried in vacuo. This yielded 18.82 g of a white solid (82.87% of the theoretical yield).

preparation example 3

Synthesis of 1-(4′-carboxy-benzyl)-3-carbamoyl-pyridinium-chloride

[0065]In a 100 ml round-bottom flask with reflux condenser, 60 ml of ethanol, 7.09 g of nicotinic acid amide (98%) (0.0569 mol), 10.22 g of 4-chloro-benzoic acid (95%) (0.0569 mol) are heated under reflux for 24 hours. After completion of the reaction, the reaction mixture is cooled to 4° C., the resulting solid is removed by filtration and dried in vacuo. This yielded 13.21 g of a white solid (79.21% of the theoretical yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com