Method for controlling streptococcus pneumoniae polysaccharide molecular weight using carbon dioxide

a technology of capsular polysaccharides and carbon dioxide, which is applied in the direction of esterified saccharide compounds, antibody medical ingredients, sugar derivates, etc., can solve the problem of low molecular weight polysaccharides (450 kda)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

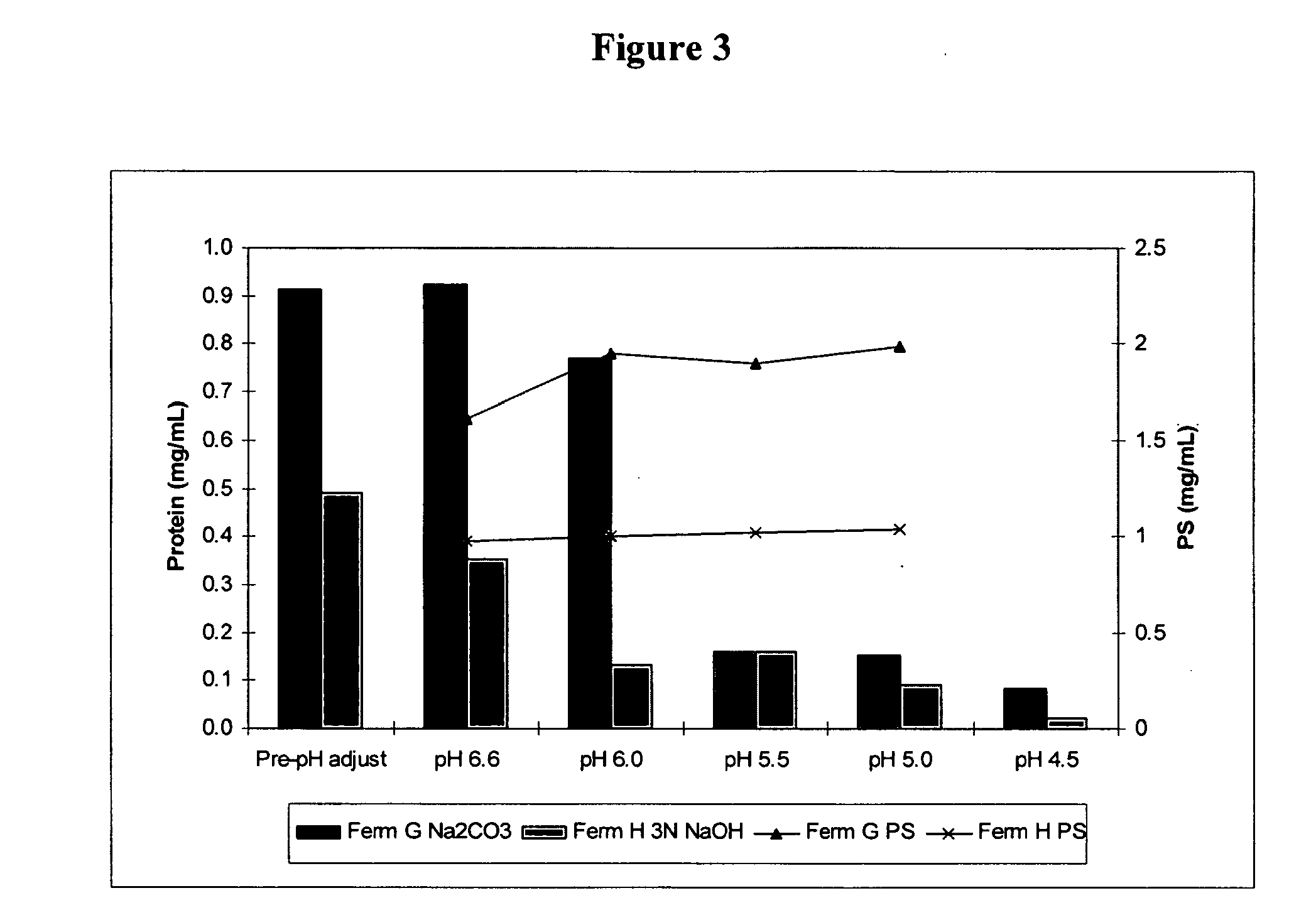

Carbon Dioxide Supply Effect on Polysaccharide Molecular Weight

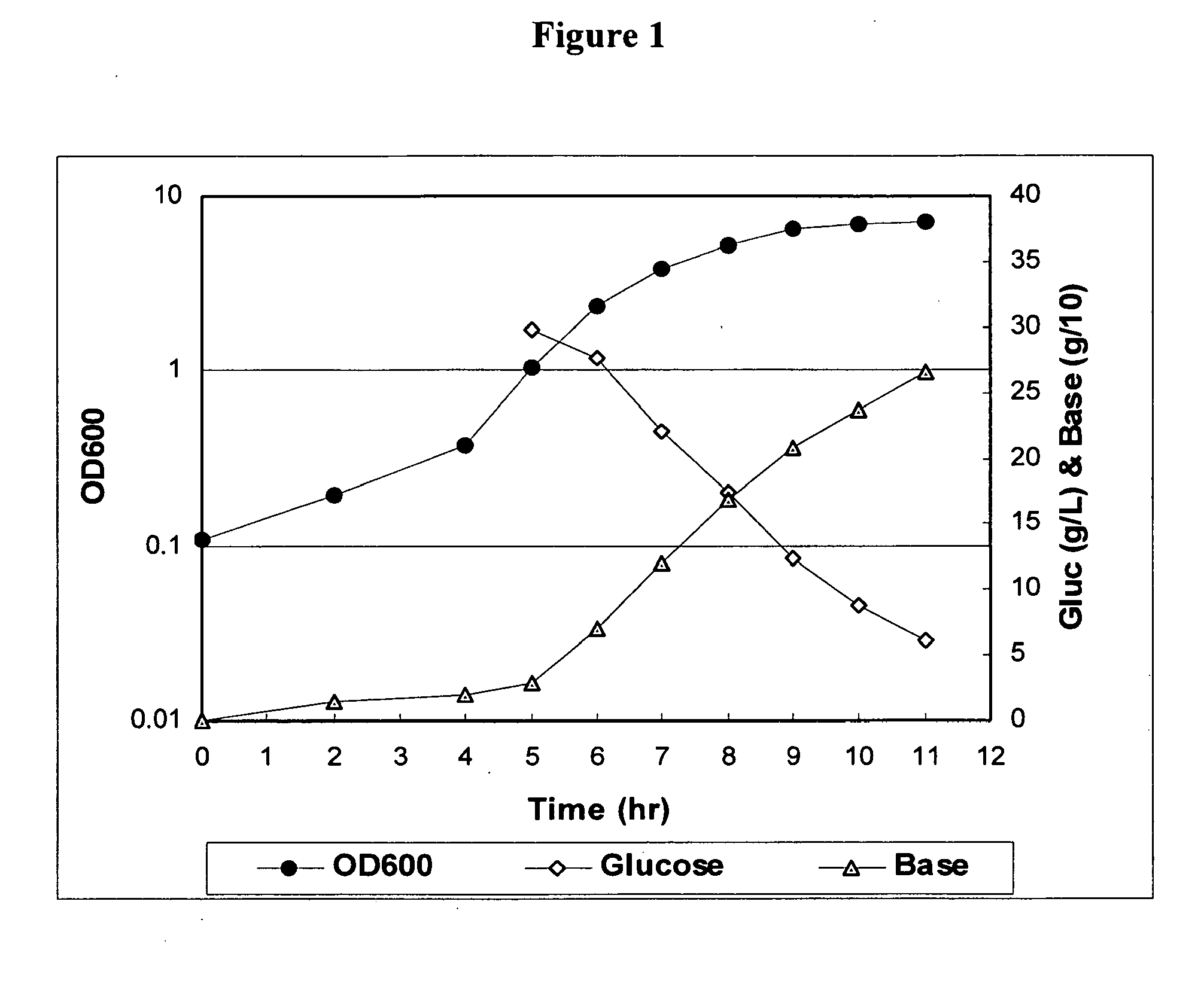

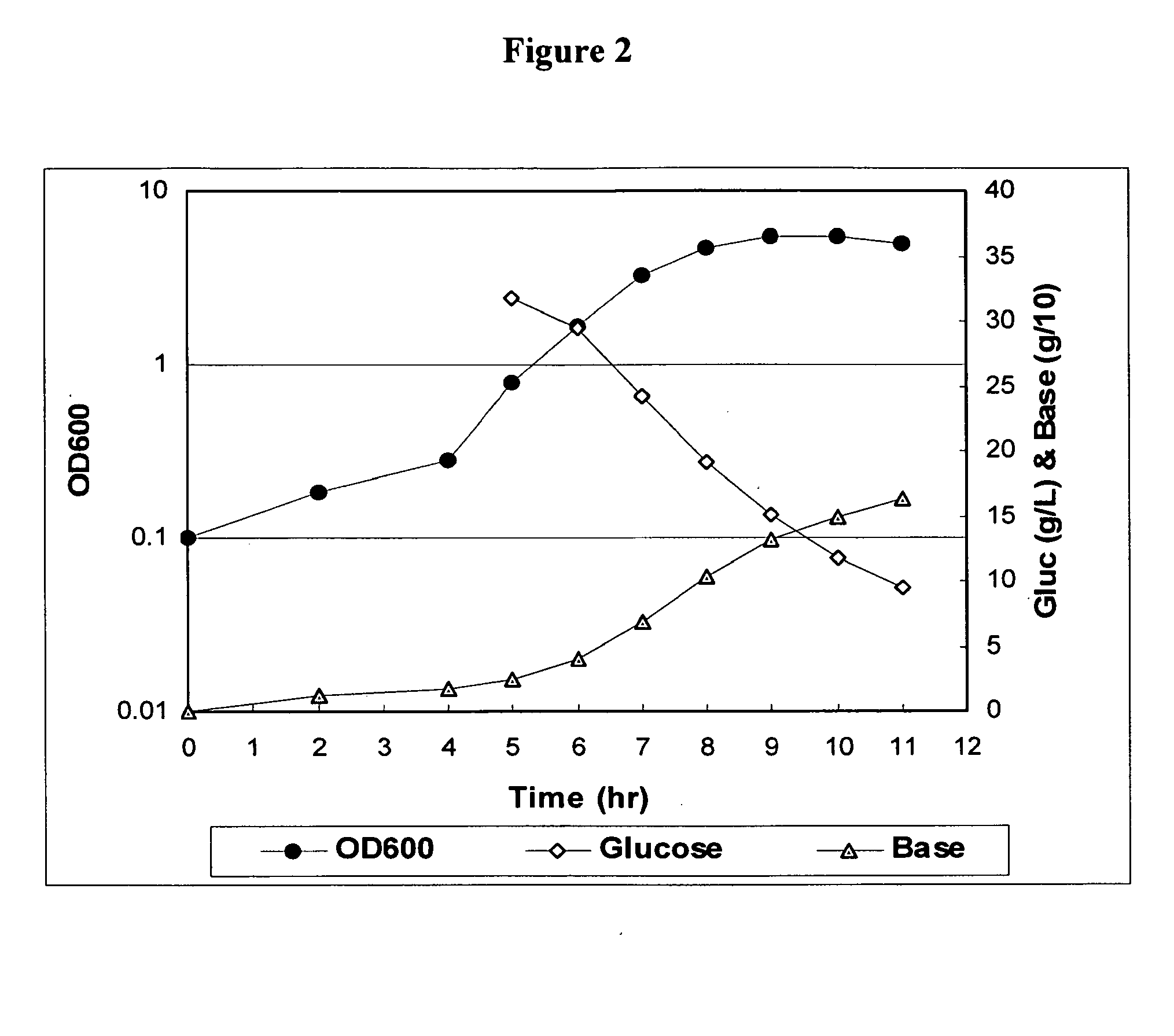

[0030]Laboratory runs were performed in 3 L Braun Biostat B fermentors (B. Braun Biotech, Allentown, Pa.). They were filled with 1.8 L of HYS medium (20 g / L HySoy, 2.5 g / L NaCl, 0.5 g / L KH2PO4, 0.013 g / L CaCl2.2H2O, 0.15 g / L L-Cysteine HCl). The fermentors were then autoclaved for 60 minutes at 121° C. After cooling, either 40 or 60 mL / L of a 50% Glucose+1% Magnesium Sulfate (w / v) (DMS) solution was added to each unit. If required, sodium bicarbonate was added prior to inoculation.

[0031]Two 2 L seed bottles containing 1 L of HYS media were inoculated with Type 19A or Type 6A frozen seed stocks and incubated at 36° C. without shaking for approximately 6-8 hours. Inoculation of the fermentors was performed with a volume of 100 mL (˜5.2% v / v) aliquoted from a bottle with an OD600 between 0.3-0.9 and pH between 4.75-5.60. The fermentation temperature and pH were controlled at the desired setpoints. The standard c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com