System and method for wastewater treatment

a wastewater treatment and wastewater technology, applied in the field of industrial wastewater treatment, can solve the problems of high labor intensity, difficult to dispose of hazardous sludge, and limited limits on the maximum concentration of certain metals,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

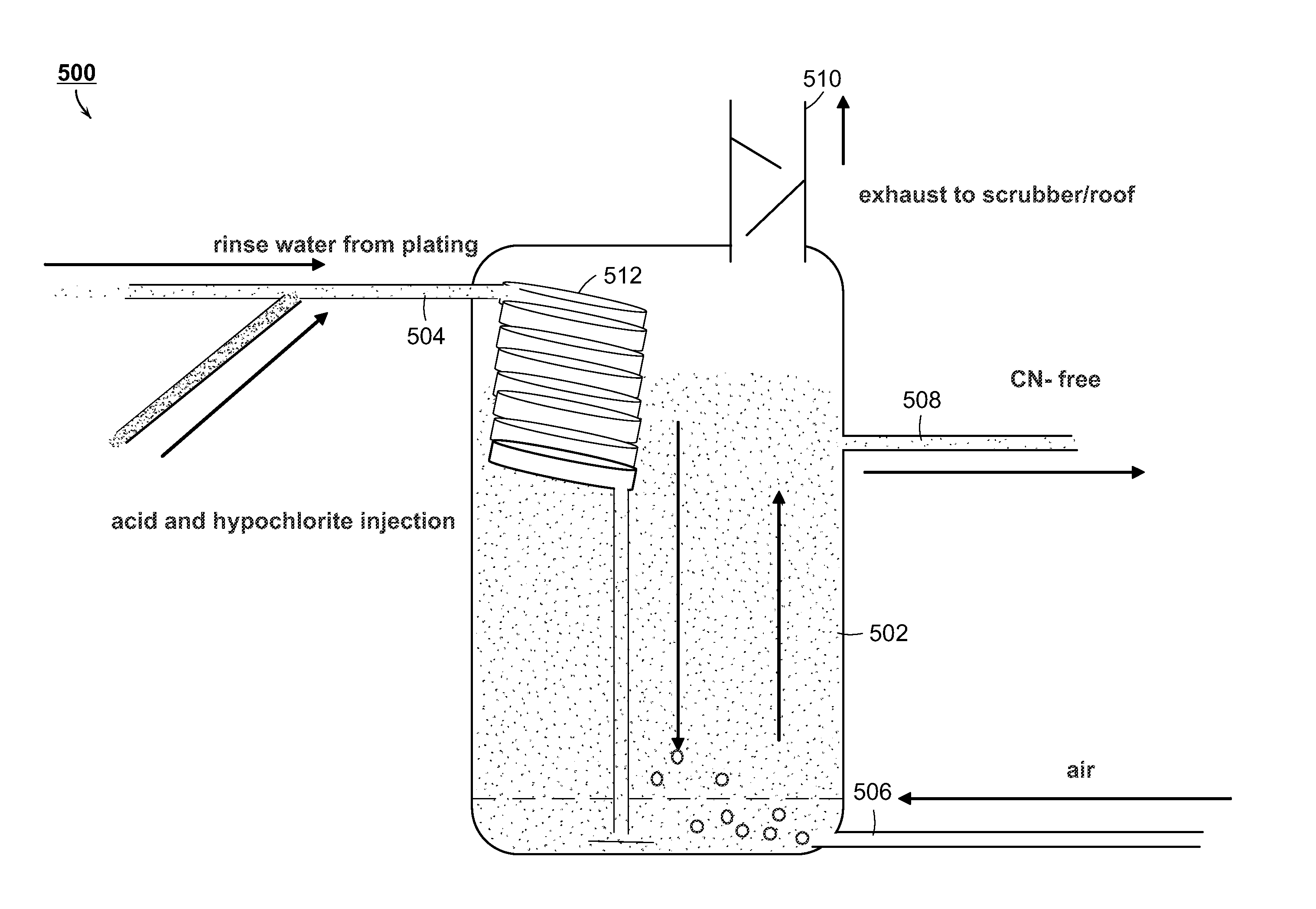

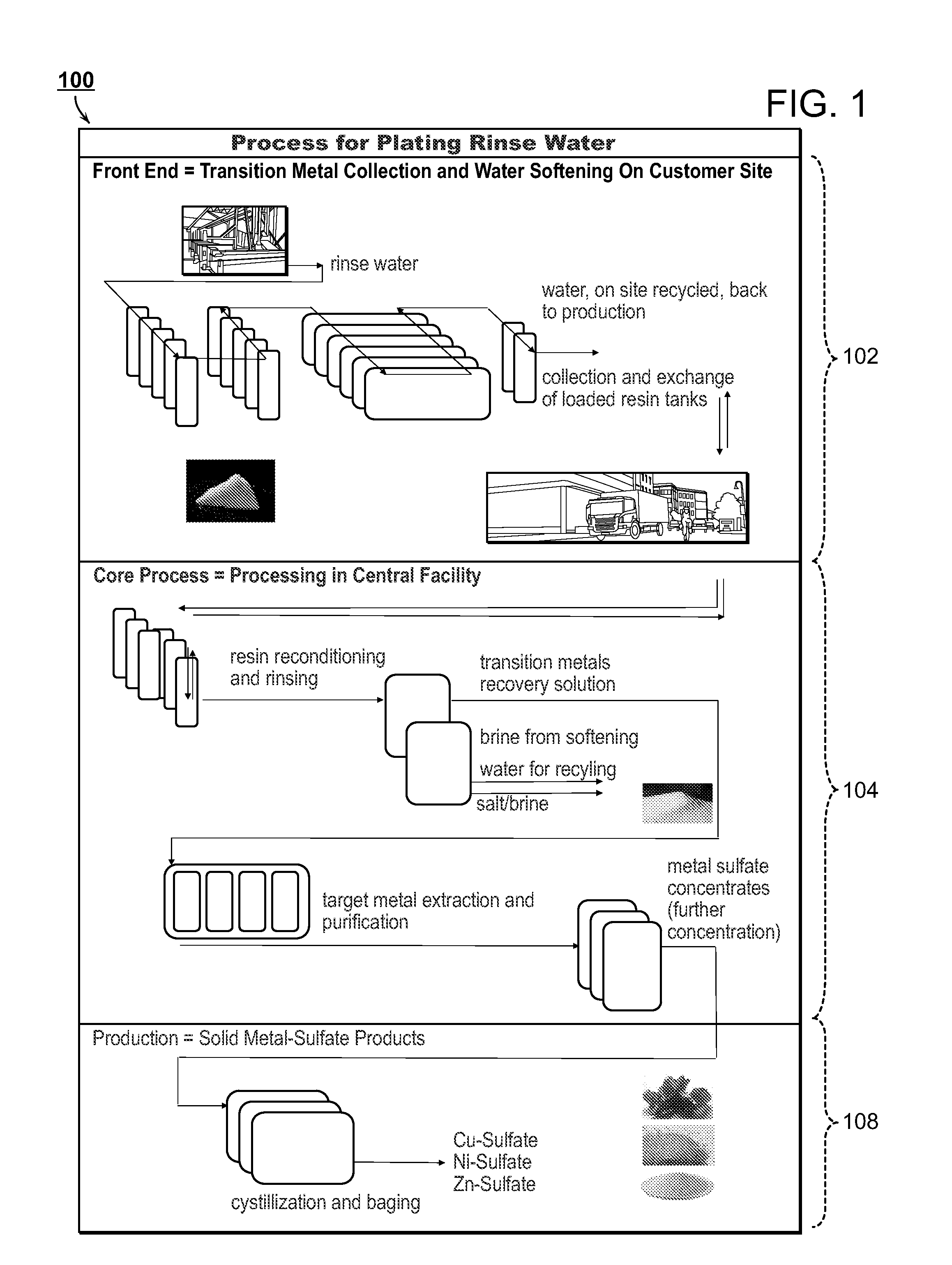

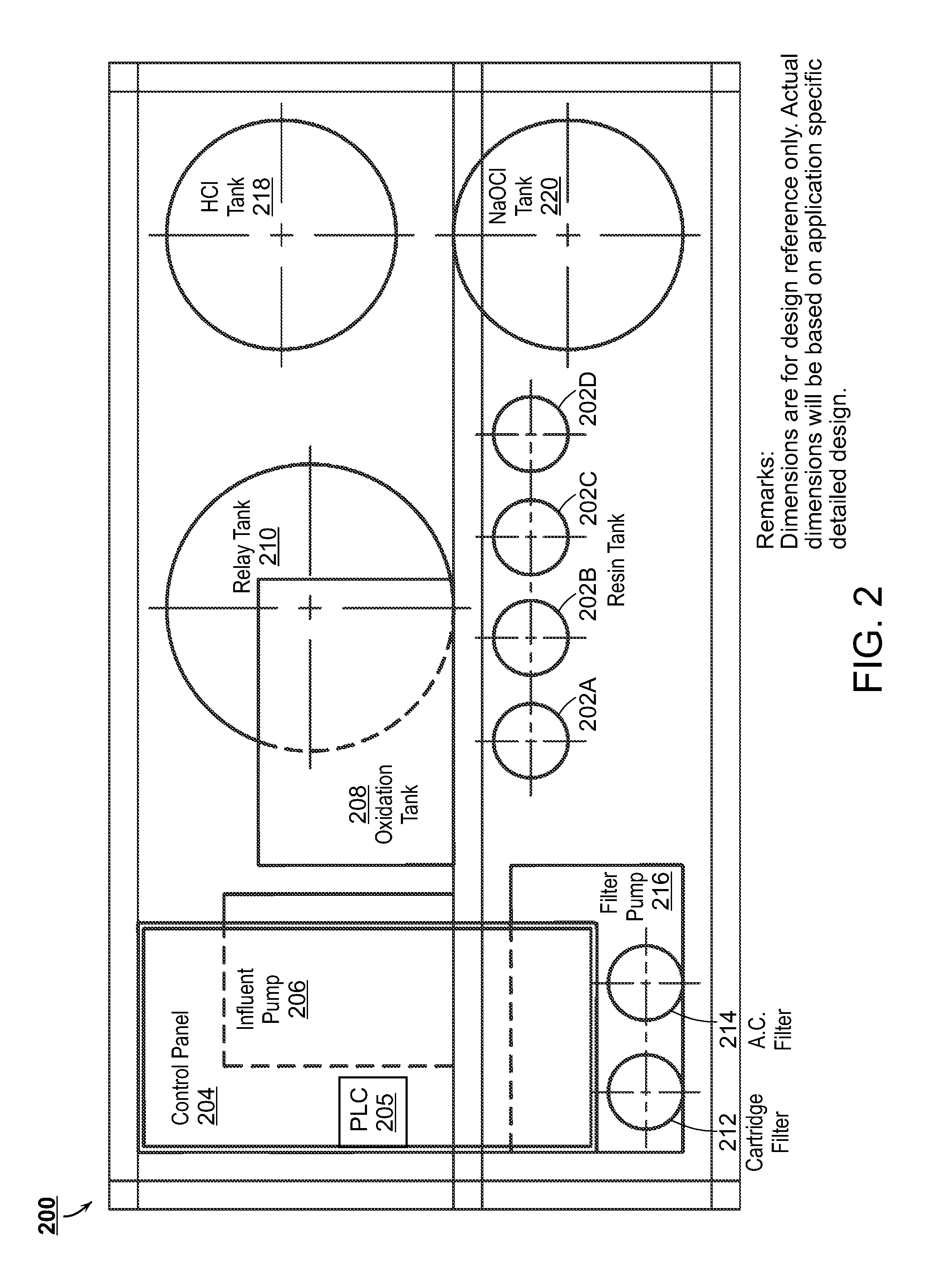

[0034]The present disclosure is directed towards an automated, modular, ion exchange resin based system that may process metal bearing wastewaters such that the treated water can be recycled, or discharged in compliance with regulatory standards. Embodiments of the present disclosure may capture the metals within the wastewater and then separate, purify and concentrate each individual metal into commercially salable end products such as metal sulfates.

[0035]The system may be comprised of a front end unit situated at the site of wastewater generation, and a central processing facility where the metal bearing ion exchange columns from numerous front end units are collected and processed. Alternatively, where treatment volumes, economic, and / or regulatory considerations so merit, the central processing facility can be located together with the front end system.

[0036]Embodiments of the present disclosure may be used to collect environmentally regulated metals from the rinse water stream...

PUM

| Property | Measurement | Unit |

|---|---|---|

| physical | aaaaa | aaaaa |

| chemical | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com