Cord, method of producing same, and rubber-cord composite body

a technology of rubber-cord and composite body, which is applied in the direction of rope making machines, yarns, textiles and papermaking, etc., can solve the problems of corroding the cord, difficult to provide spaces for allowing the rubber to sufficiently intrude into the inside of the strand, and difficulty in ensuring the integrity of the strand. , to achieve the effect of suppressing twisting and improving corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

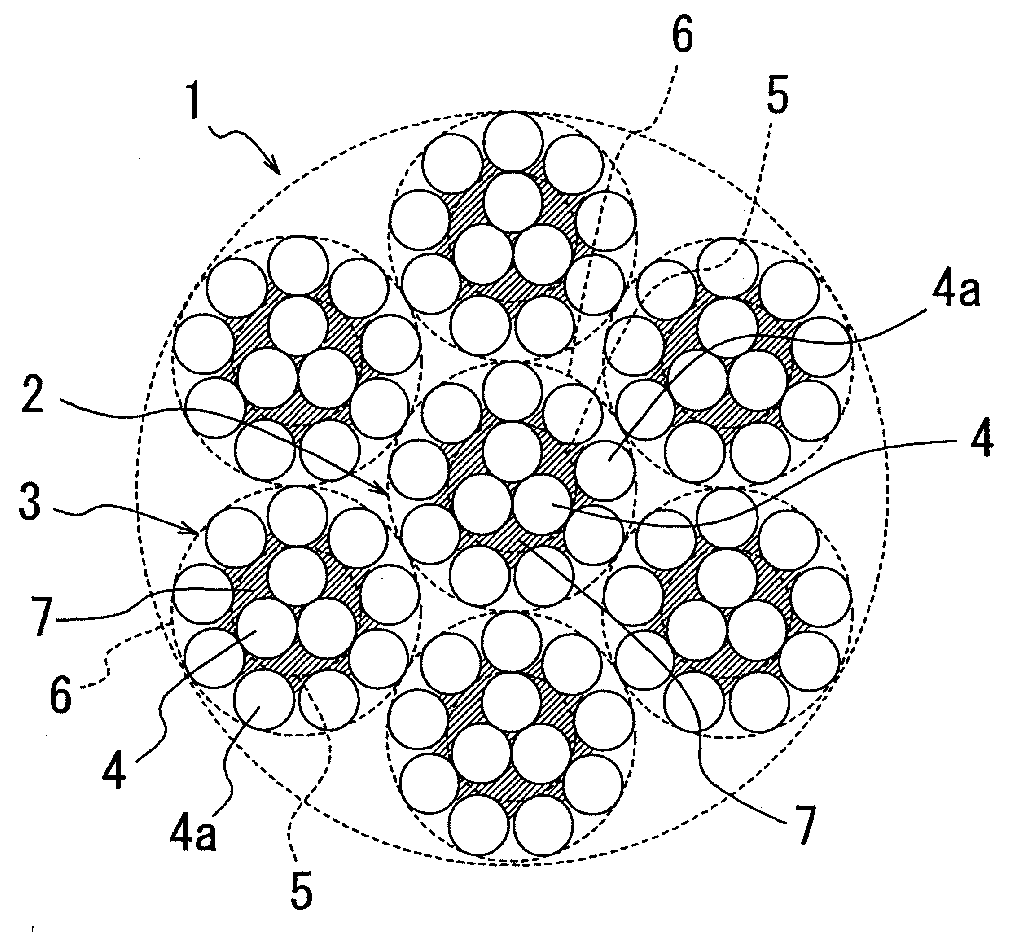

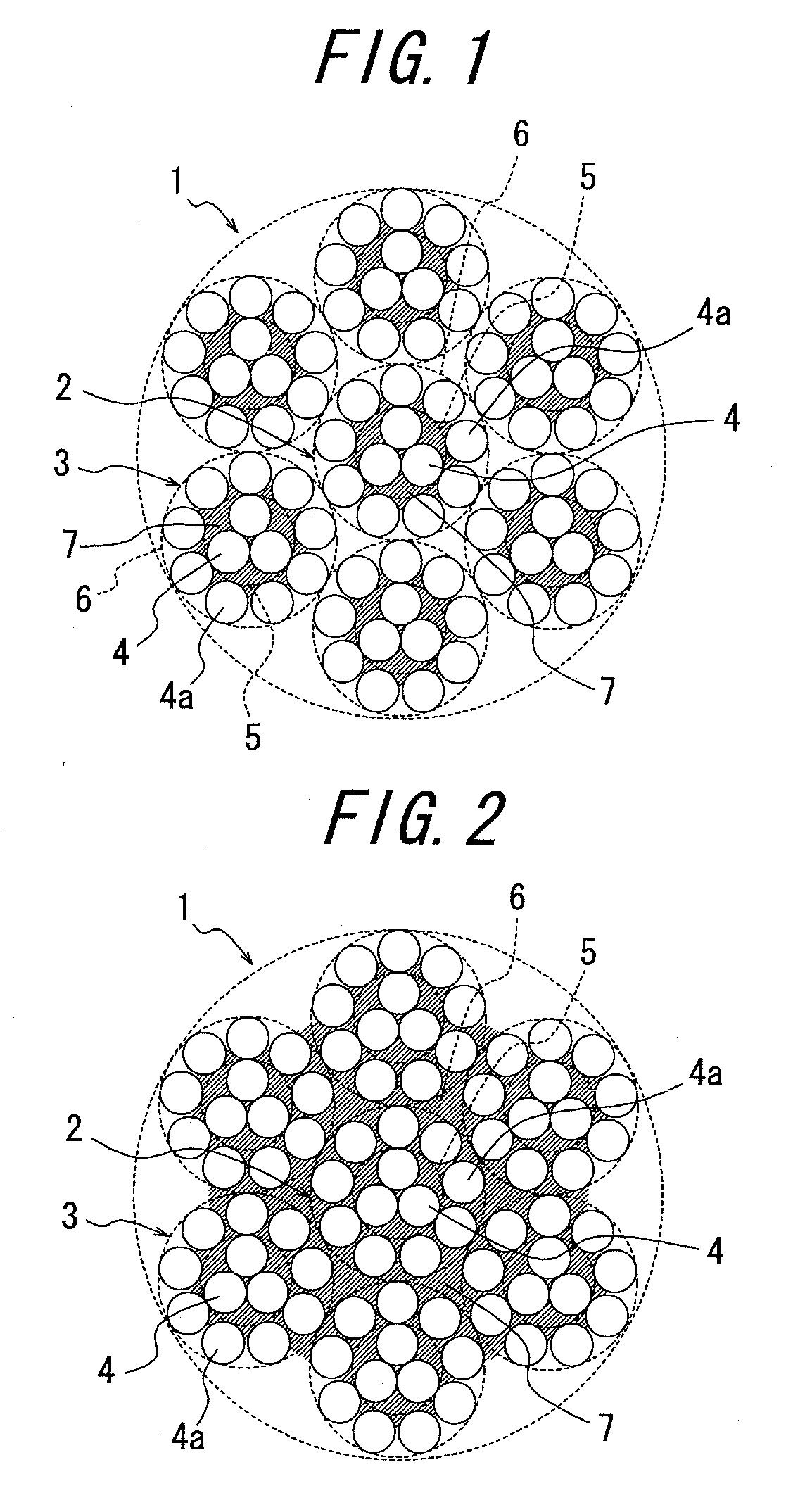

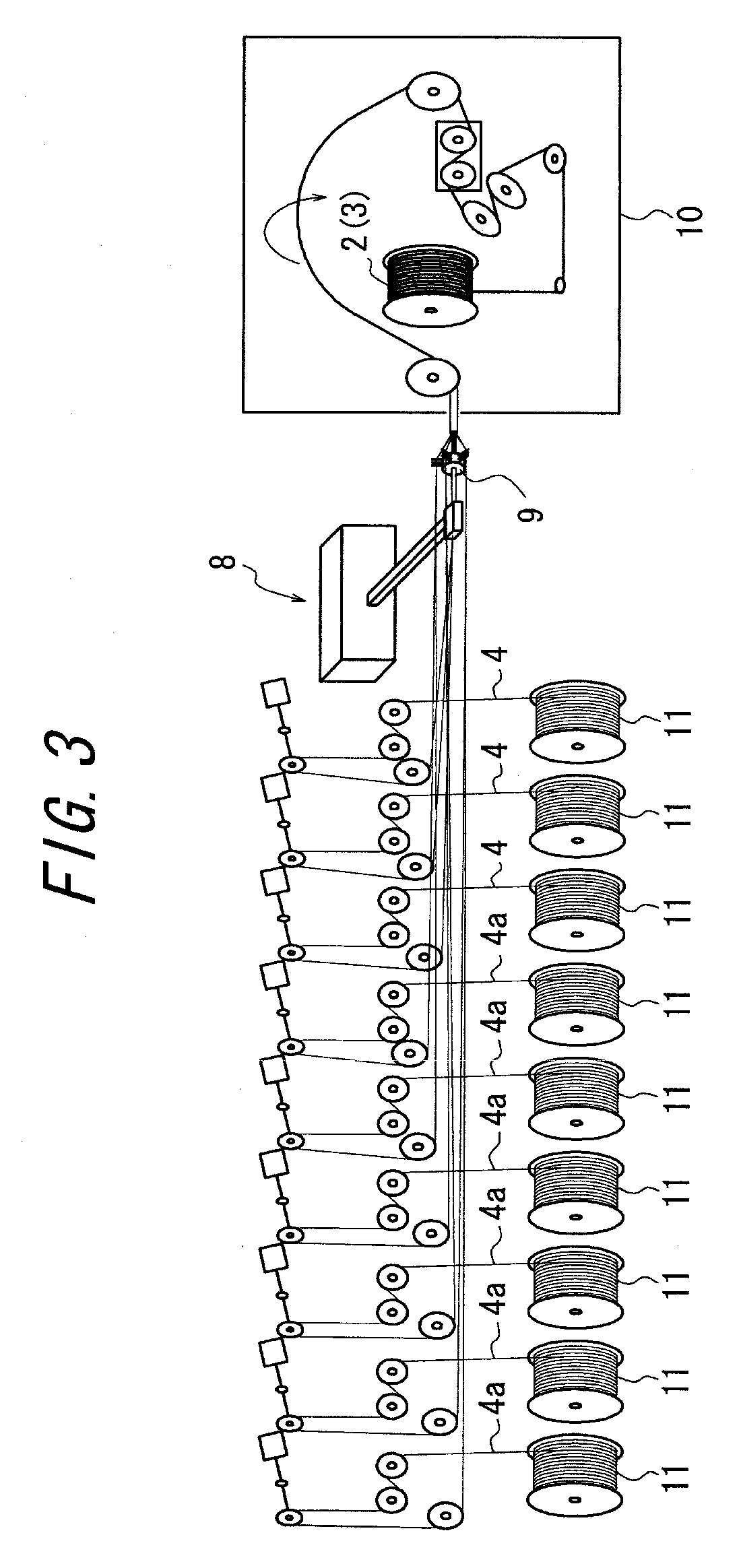

[0071]Various cords are manufactured under the specifications shown in Tables 1 and 2. The structures of the cords are shown in FIGS. 1, 2 and 5-18. It is noted that each of FIGS. 15-18 shows a sectional view of a conventional cord and each of FIGS. 1, 2 and 5-14 shows a sectional view of a cord according to the present invention.

[0072]A ply in which a plurality cords according to the present invention are arranged in parallel with each other and embedded in a rubber sheet with a given space therebetween is applied to a belt and a test tire is built with using this belt. The test tire is examined in relation to a ratio (%) of rubber intruding inside of a core strand of a cord used for reinforcement, a ratio (%) of rubber intruding inside of a sheath strand, a ratio (%) of rubber intruding between the core strand and the sheath strand, and twisting loss (%). In addition, the number of steps is also examined in the method of producing a cord according to the present invention.

[0073]In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com