Metal panel fencing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

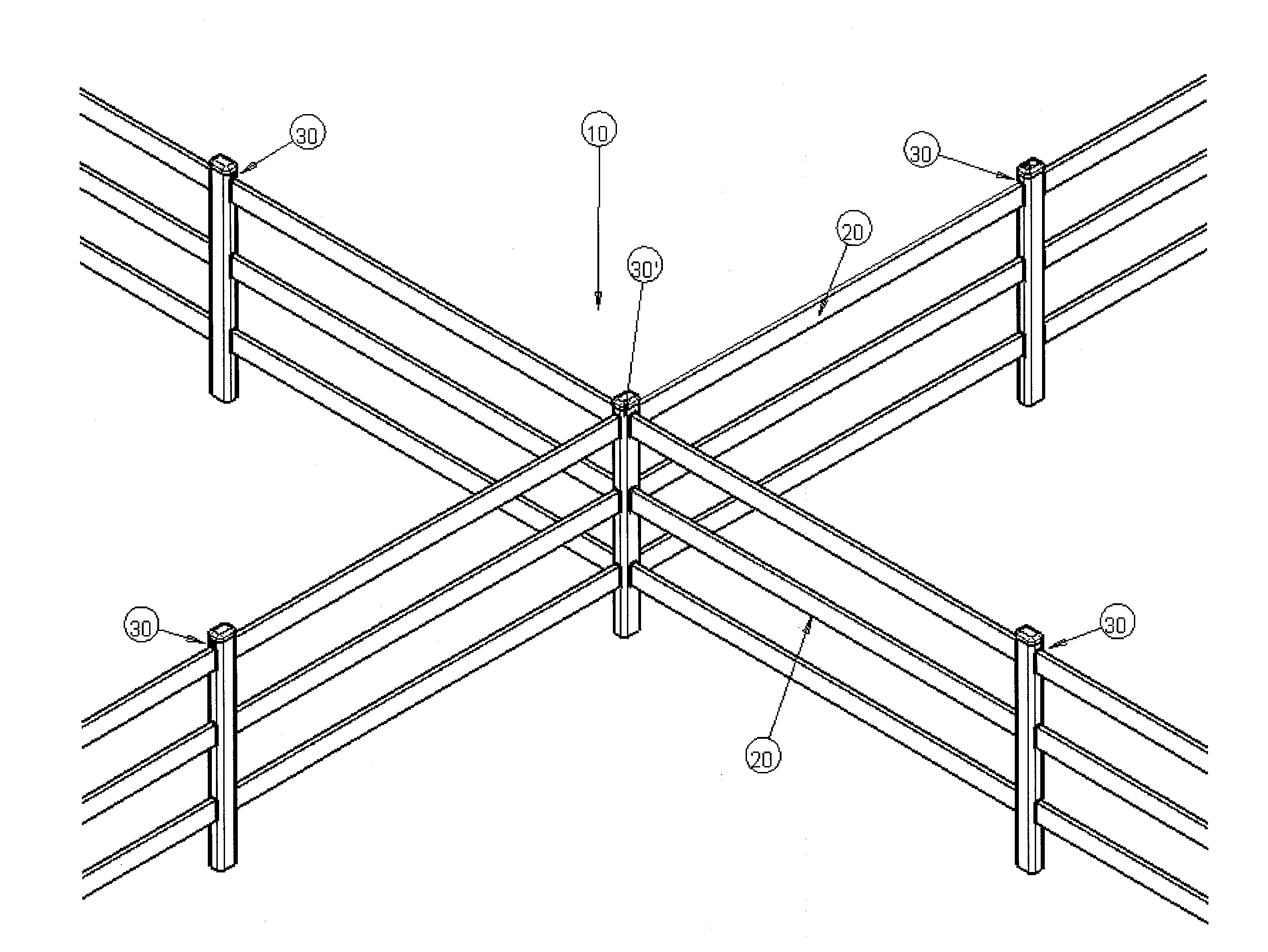

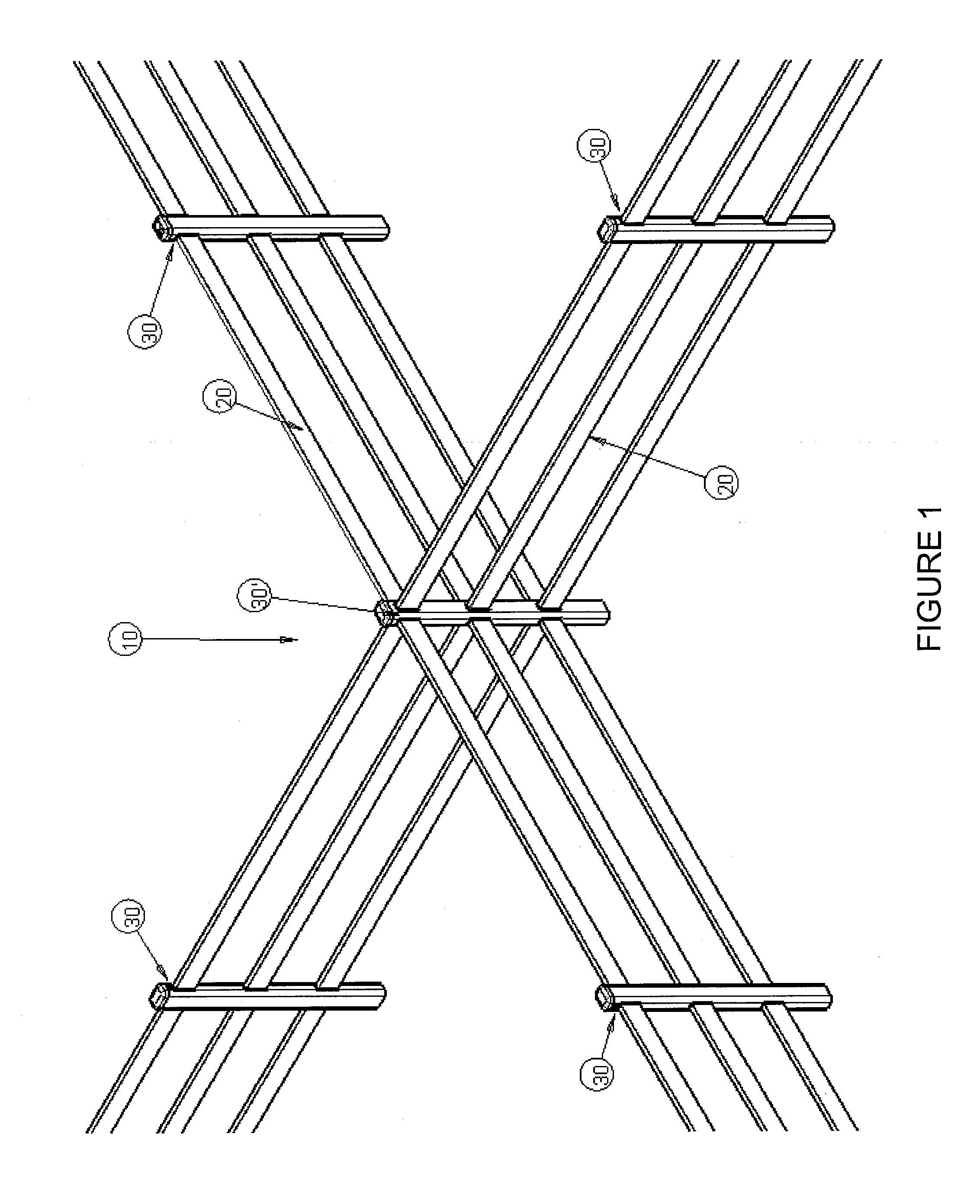

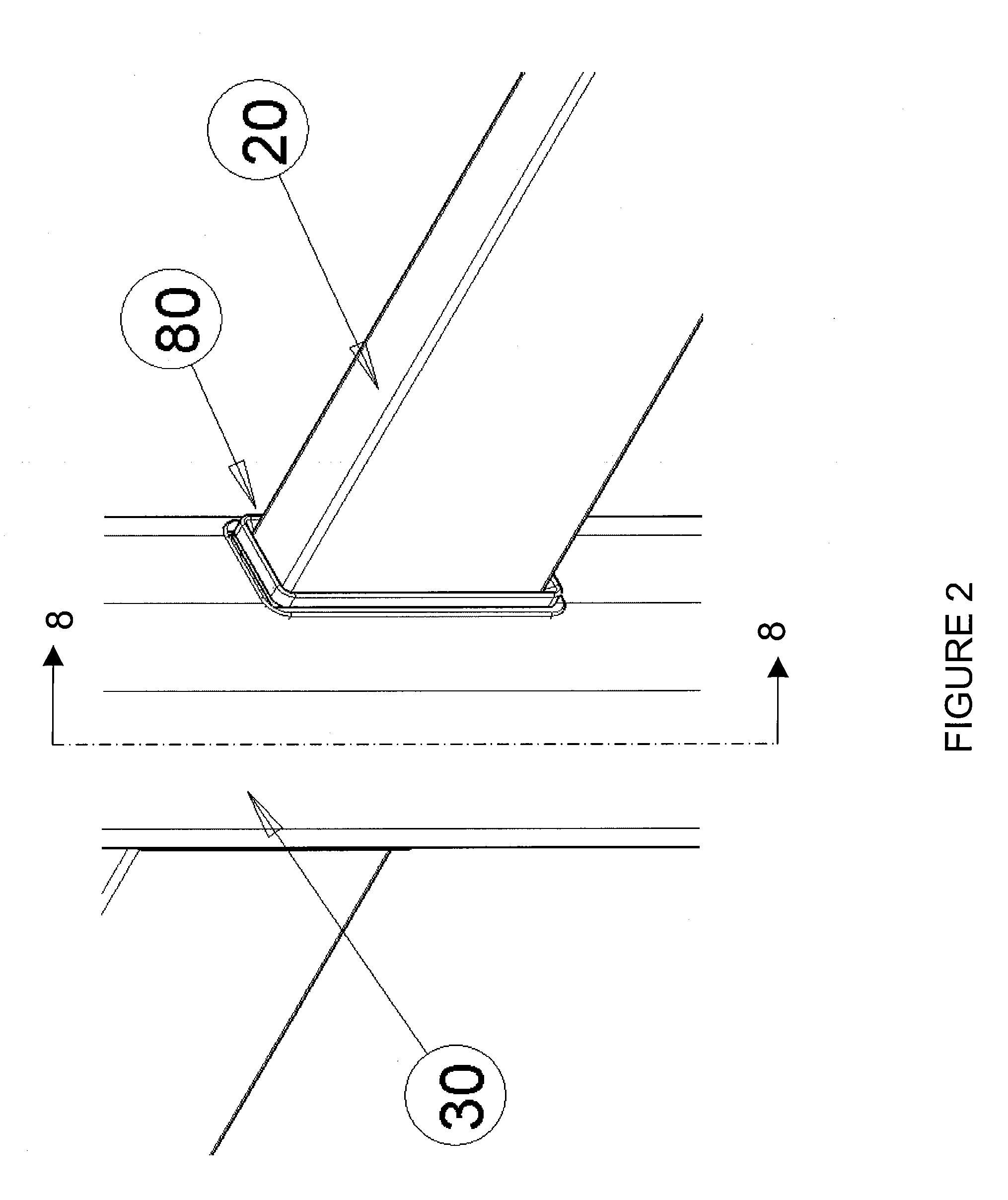

[0038]Referring to FIG. 1, a fencing system 10 constructed in accordance with an exemplary embodiment of the invention is illustrated. FIG. 1 illustrates a three-rail fencing system with examples of both two-way and four-way post interconnections. It is contemplated that this fencing system 10 may also be constructed as a two or a four-rail fencing system, not illustrated, and alternately, the fencing system 10 may use any other number of rails as appropriate in a particular application. The rail system comprises fence members in the form of rails or rail panels 20 and posts 30 and 30′ that support the rails. The rails 20 are mounted in openings 32 in the posts 30 and 30′ by compliant couplers 80 and clips 40 in a manner that permits the rails 20 to extend at vertical or horizontal angles relative to the posts 30 and 30′. All components of the fencing system 10 are designed to render the system 10 as a whole easy to assemble, versatile, and aesthetically attractive.

[0039]Referring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com