Aluminum oxide sintered body, method for producing the same and member for semiconductor producing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Examples 1 to 9 and Comparative Examples 1 to 6

[0034]Aluminum sintered bodies of Examples 1 to 9 and Comparative Examples 1 to 6 were prepared and evaluated. Contents thereof will be detailed below.

[0035]1. Powder of Raw Material

[0036]Powders of raw materials shown below were used. A commercially available Al2O3 powder having a purity of 99.5% or more and an average particle diameter of 0.6 μm was used. A commercially available oxide powder such as europium oxide having a purity of 99.9% or more and an average particle diameter of 2 μm or less was used. An AlN powder containing impurity oxygen of 0.87% by weight and having an average particle diameter of 1.1 μm was used. Average particle diameters of the raw material powders are values measured by a laser diffraction method.

[0037]2. Powder Mixture

[0038]The respective powders were measured in the parts by weight shown in Table 1 and wet-mixed in a solvent of isopropyl alcohol in a polyethylene pot with alumina pebbles having a diamet...

Example

[0051]Still furthermore, in Comparative Examples 3 and 4, in place of AlN, CeO2 was added, and in Comparative Example 5, in place of AlN, Pr6O11 was added. In Comparative Example 3, irrespective of such a small thickness of a sintered body as 5 mm, the inside to outside ratio ρin / ρout was as large as 1.7. Furthermore, in Comparative Example 4, although the thickness of the sintered body was as large as 10 mm, the same as in the respective Examples, the inside to outside ratio ρin / ρout became even larger such as 2.2. In Comparative Example 5 as well, although the thickness of the sintered body was as large as 10 mm, the same as in the respective Examples, in this case, the inside to outside ratio ρin / ρout became very large such as 20. From these results, it was found that AlN is highly effective at suppressing a distribution of the volume resistivity over the whole sintered body in comparison with CeO2 and Pr6O11.

Example

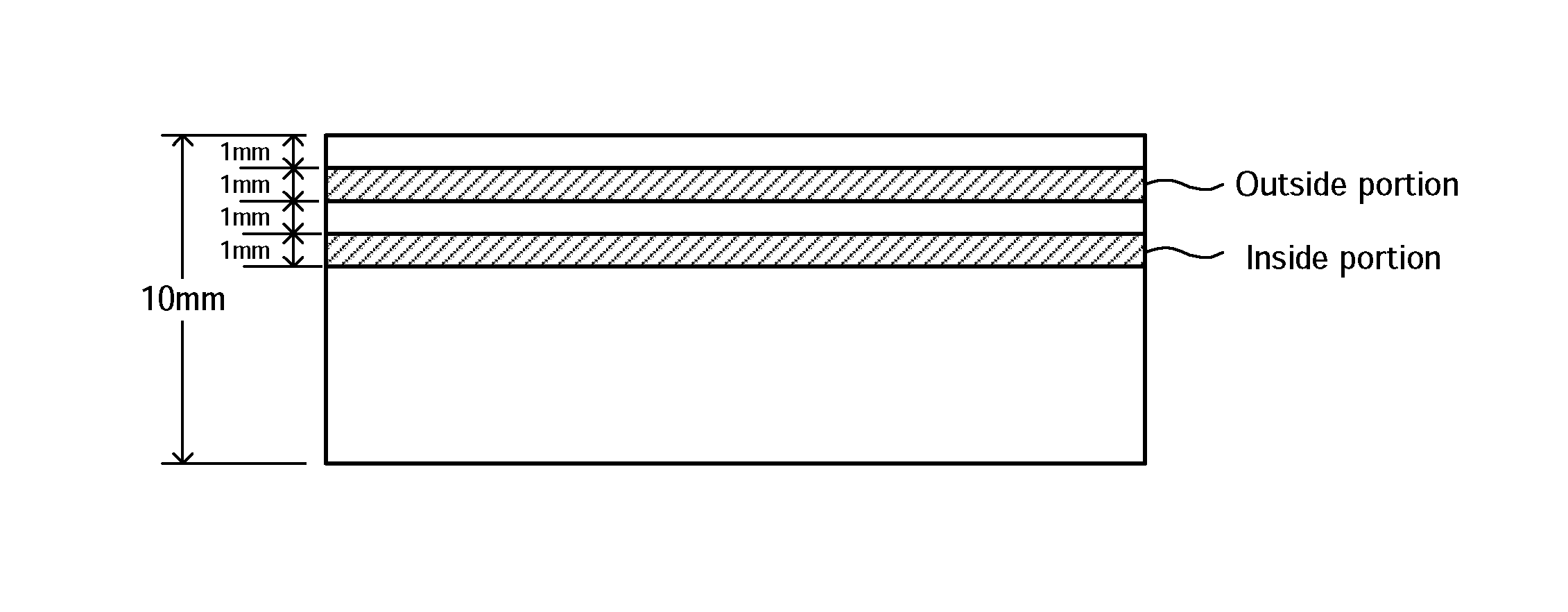

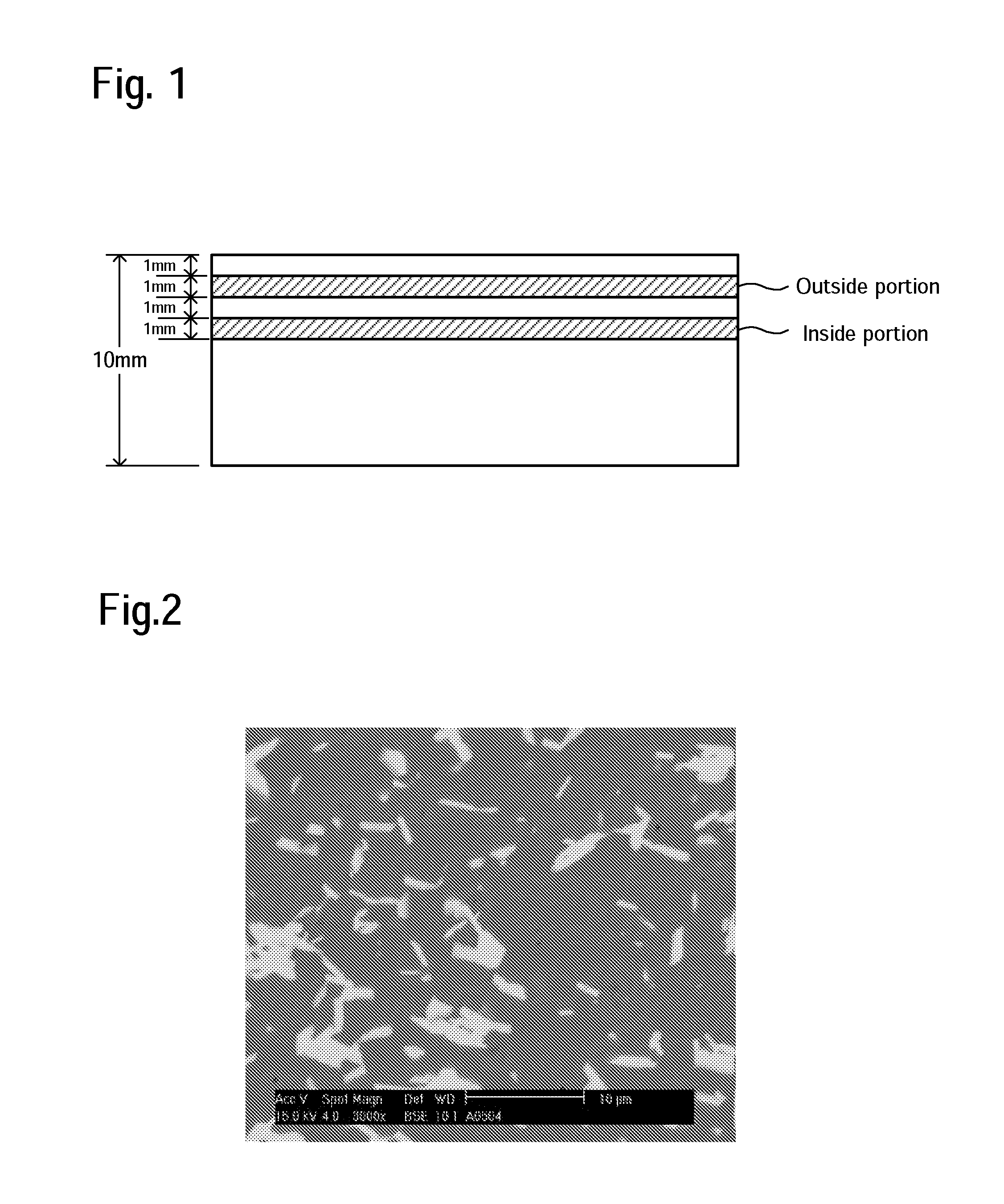

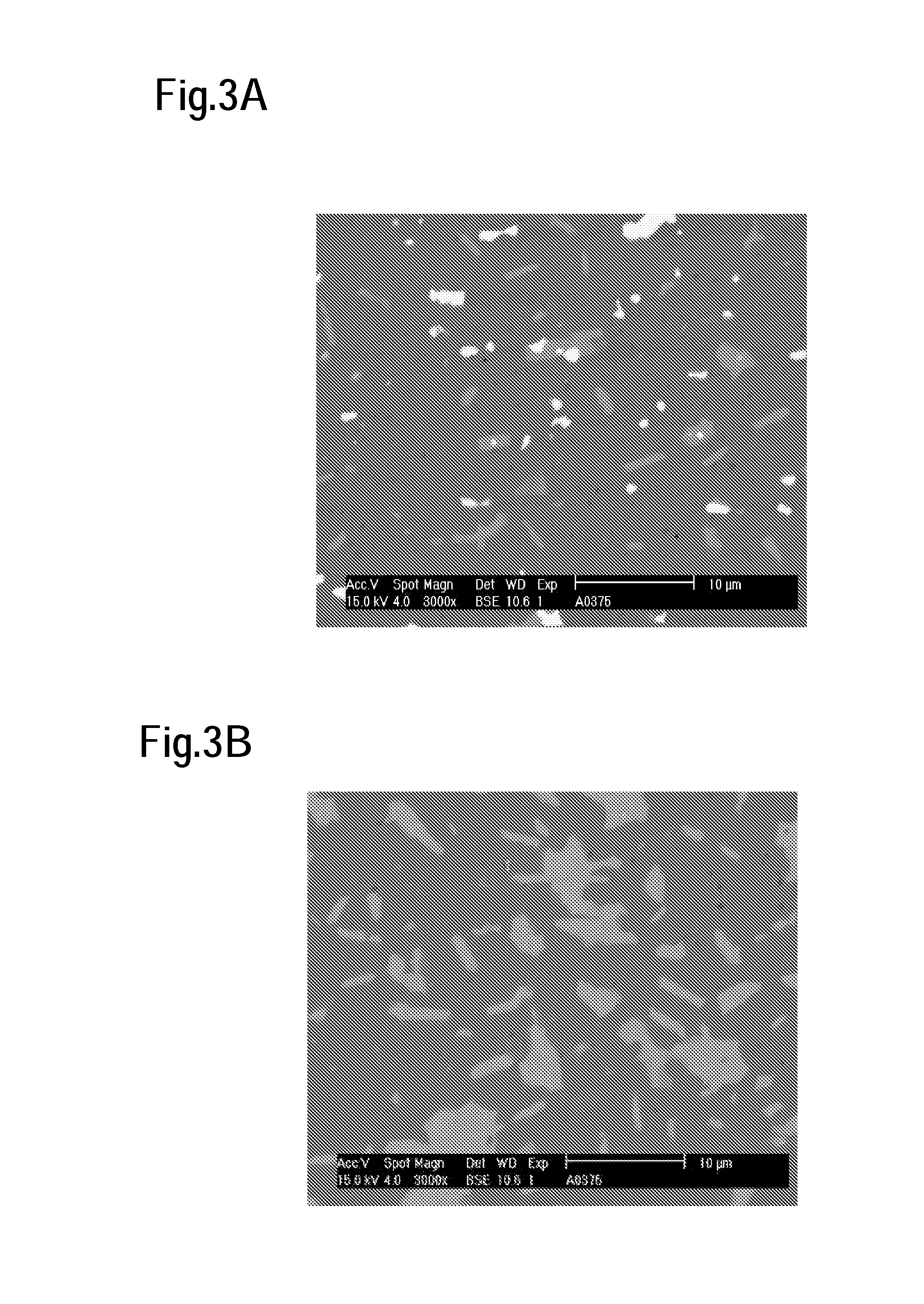

[0052]In FIG. 2, a SEM photograph of a mirror-polished cross-section of Example 7 is shown, and, in FIG. 3, SEM photographs of a mirror-polished cross-section of Comparative Example 2 are shown. FIG. 3A is a SEM photograph of an inside portion of Comparative Example 2 and FIG. 3B is a SEM photograph of an outside portion of Comparative Example 2. Of the respective SEM photographs, a deep grey portion forming a background shows Al2O3, thin grey portions scattered in plate show crystals having peaks coinciding with EuAl12O29, and brilliant white portions found only in FIG. 3A show crystals having peaks coinciding with EuAlO3. As is obvious from the SEM photographs, in the sintered body of Example 7, EuAlO3 was not present, and plate-like crystals having peaks coinciding with EuAl12O19 were dispersed. On the other hand, in Comparative Example 2, in an outside portion, plate-like crystals having peaks coinciding with EuAl22O29 were dispersed and crystals having peaks coinciding with EuA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com