Command and arm fuze assembly having small piston actuator

a piston actuator and fuze technology, applied in the direction of ammunition fuzes, weapons, weapon components, etc., can solve the problems of large spread in distance, inability to carry out large-scale deployment, so as to eliminate the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The command to arm / safe and arm device assembly ensures that a warhead can not explode until after a round has reached the specified no arm distance for the round.

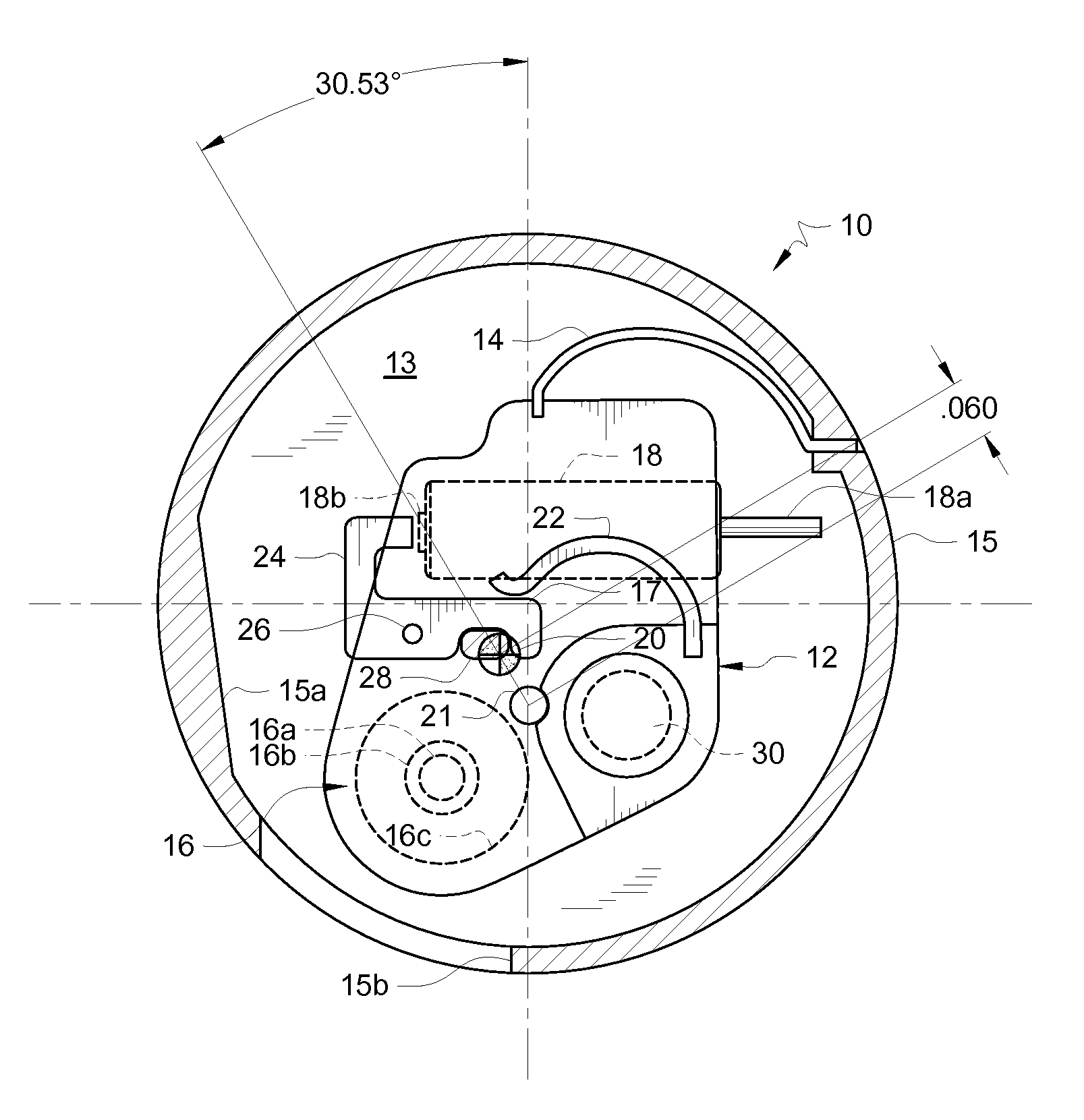

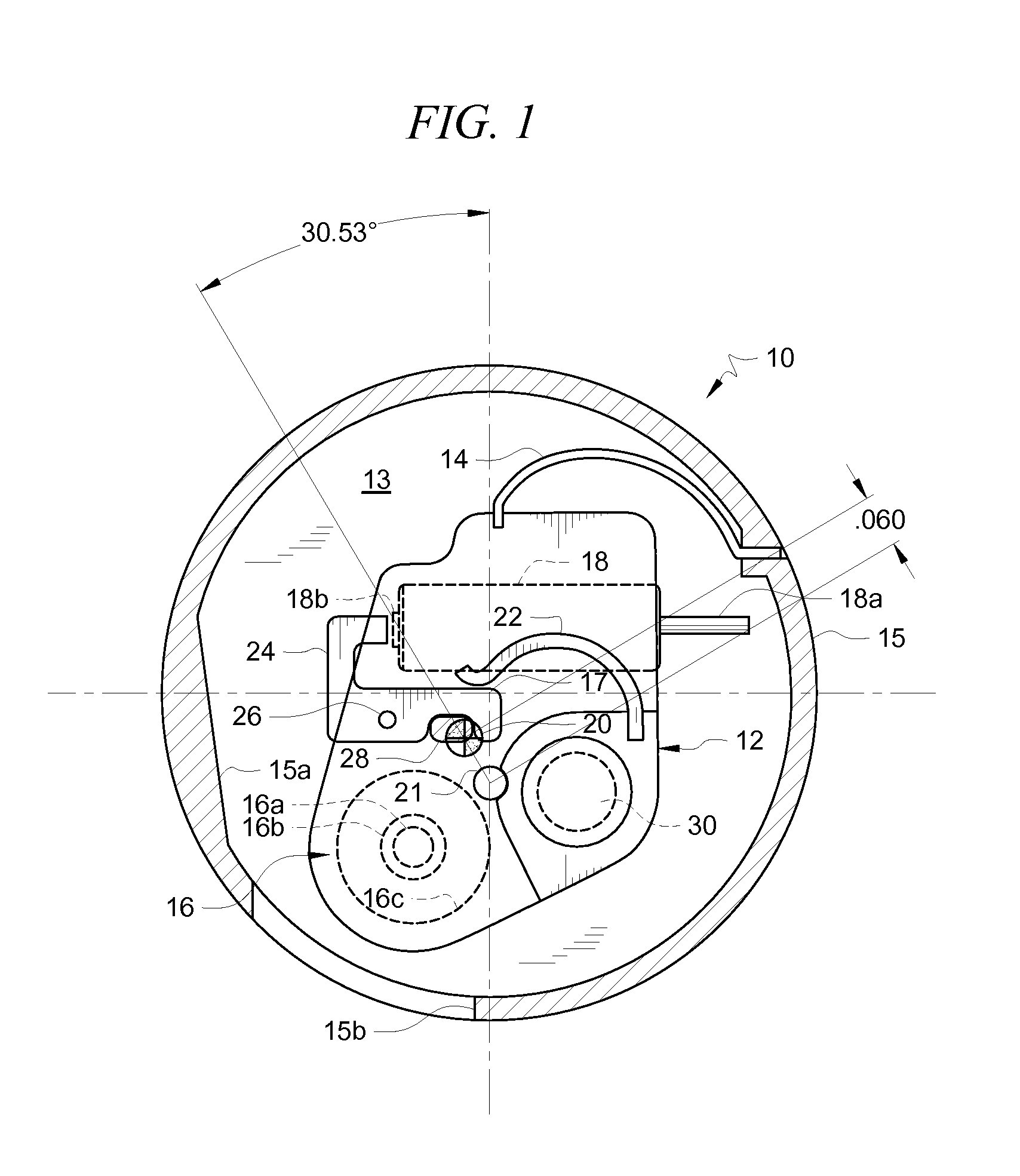

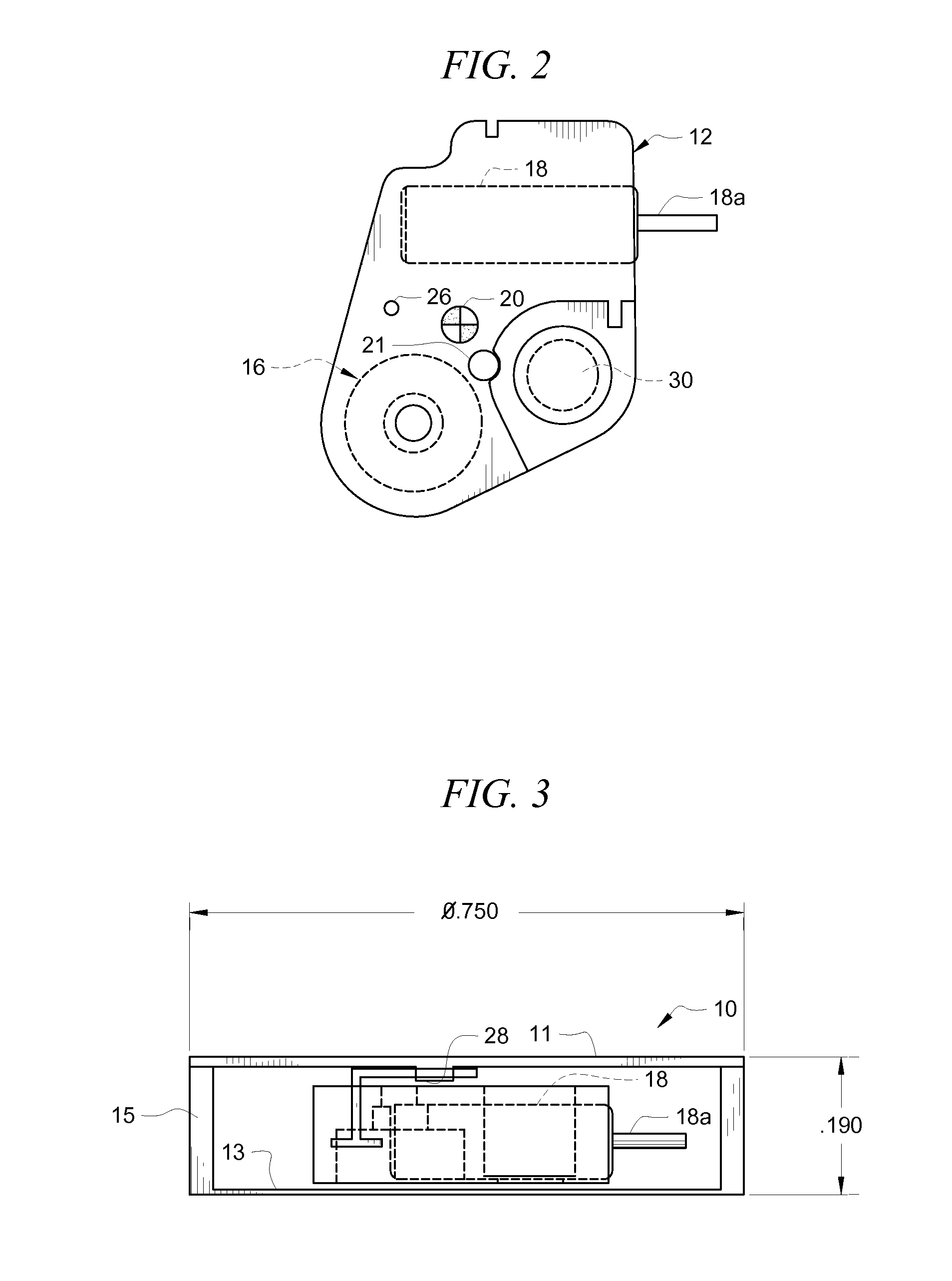

[0030]Referring now to FIGS. 1 and 2, it will there be seen that an illustrative embodiment of the novel command to arm system is denoted as a whole by the reference numeral 10. Command to arm housing 10 has a hollow interior defined by cover 11, depicted in FIG. 3, bottom wall 13, and substantially circular sidewall 15. Flat 15a and opening 15b are formed in said sidewall 15. Center point 17 is the longitudinal axis of symmetry of housing 10. It is indicated by vertical line 17a and horizontal line 17b that pass through said longitudinal axis of symmetry.

[0031]Rotor 12 is depicted in FIG. 1 in the safe position as manufactured. It is held by two different locks as required by governmental safety regulations. These locks unlock the rotor upon gun launch.

[0032]First lock 14 is a centrifugal lock spring that releases r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com