Molded rubber article

a technology of molded rubber and articles, which is applied in the direction of rigid containers, flexible containers, packaged goods, etc., can solve the problems of insufficient adhesion strength, inability to adhere to a bare rubber surface, and inability to achieve sufficient adhesion properties, etc., to achieve high adhesion properties, not easily detached, and high adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0084]A molded rubber article (a rubber plug) which has a cross section shown in FIG. 1(A) was produced by the following process.

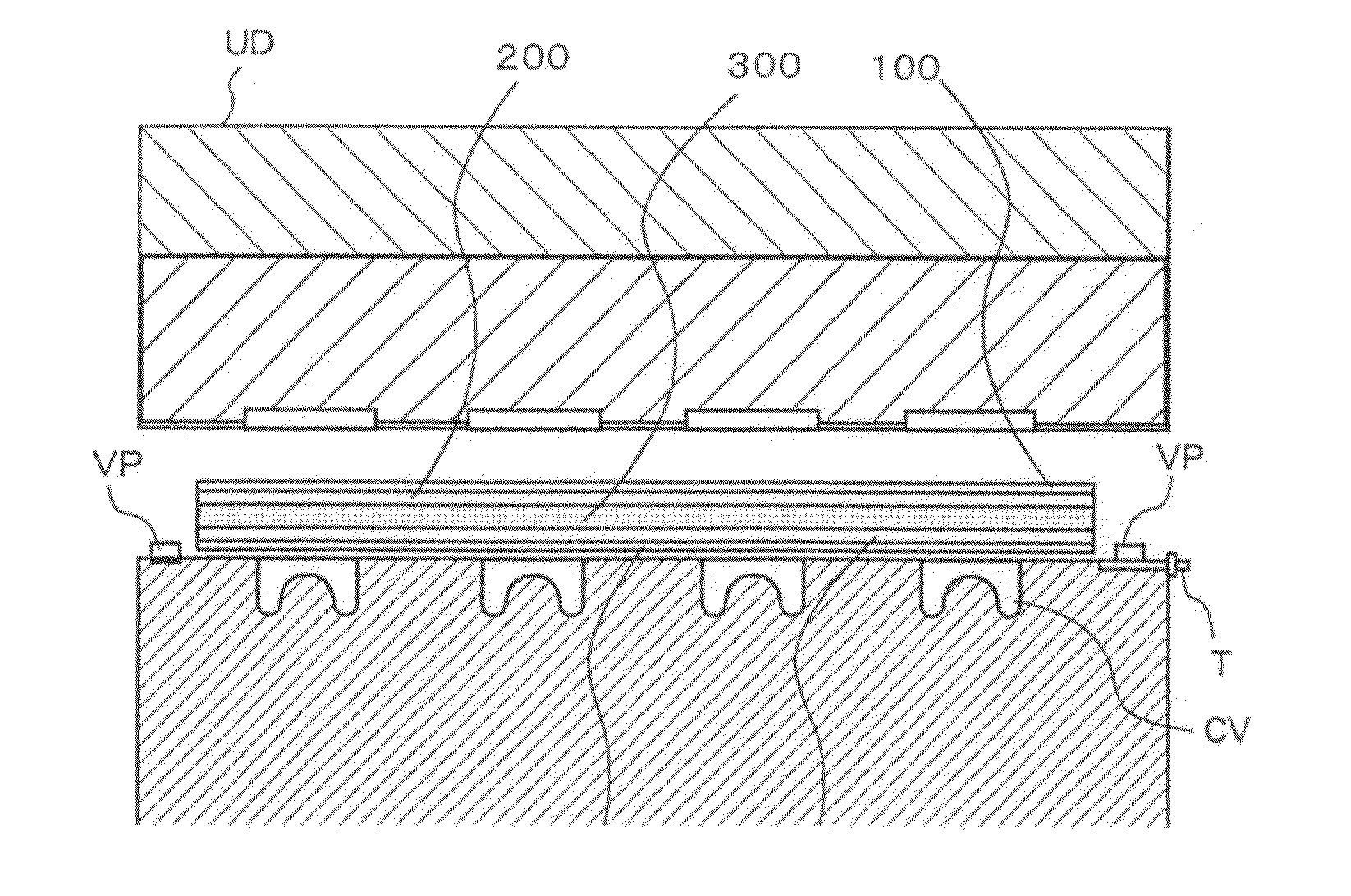

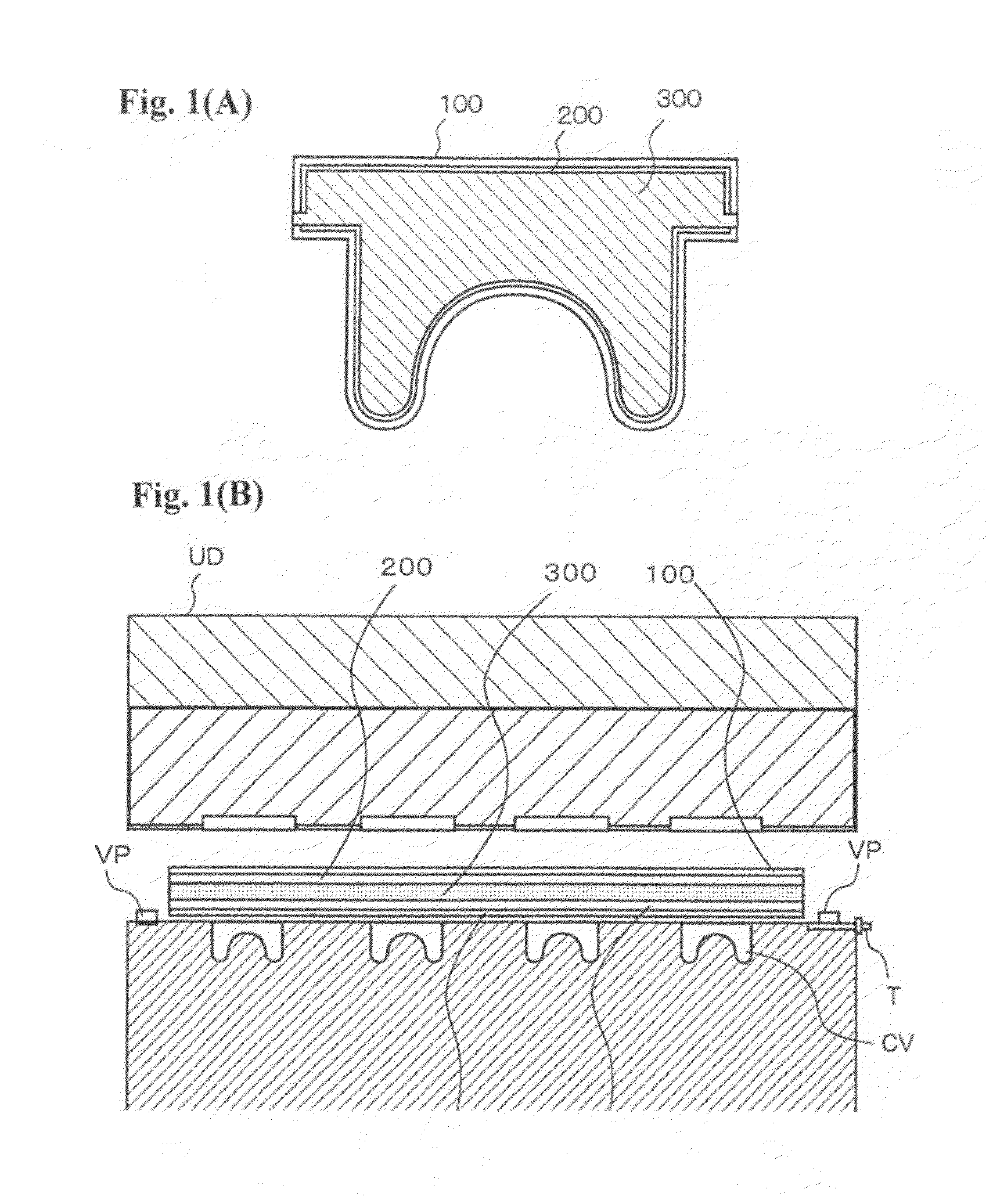

[0085]FIG. 1(A) shows a rubber member 300 molded in a shape of a rubber plug, a fluorine resin film layer 100 for covering at least the surface of the rubber plug which may contact medicinal chemicals (the entire surface of the rubber plug in this example) and a polyolefin film layer 200 interposed between the rubber member 300 and the fluorine resin film layer 100.

[0086]A SIBS elastomer (Kaneka Corp. “SIBSTAR ®”) of 100 pts.wt. and a cross-linking agent (polysiloxane including hydroxy group) of 2 pts.wt. are kneaded by an open roll, and a sheet-shaped rubber member of a thickness of 10 mm was obtained by heating after aging for 24 hours.

[0087]A PTFE film 100 of a thickness of 50 μm and an ultrahigh molecular weight polyethylene film 200 of a thickness of 50 μm having a molecular weight of 5.5 millions were put on the lower mold tool LD of the mold tool sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Thermoplasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com