Smoking article with modified smoke delivery

a technology of modified smoke and smoking articles, applied in the direction of tobacco, non-fibrous pulp addition, applications, etc., to achieve the effect of reducing weight and reducing weight of tobacco per unit length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

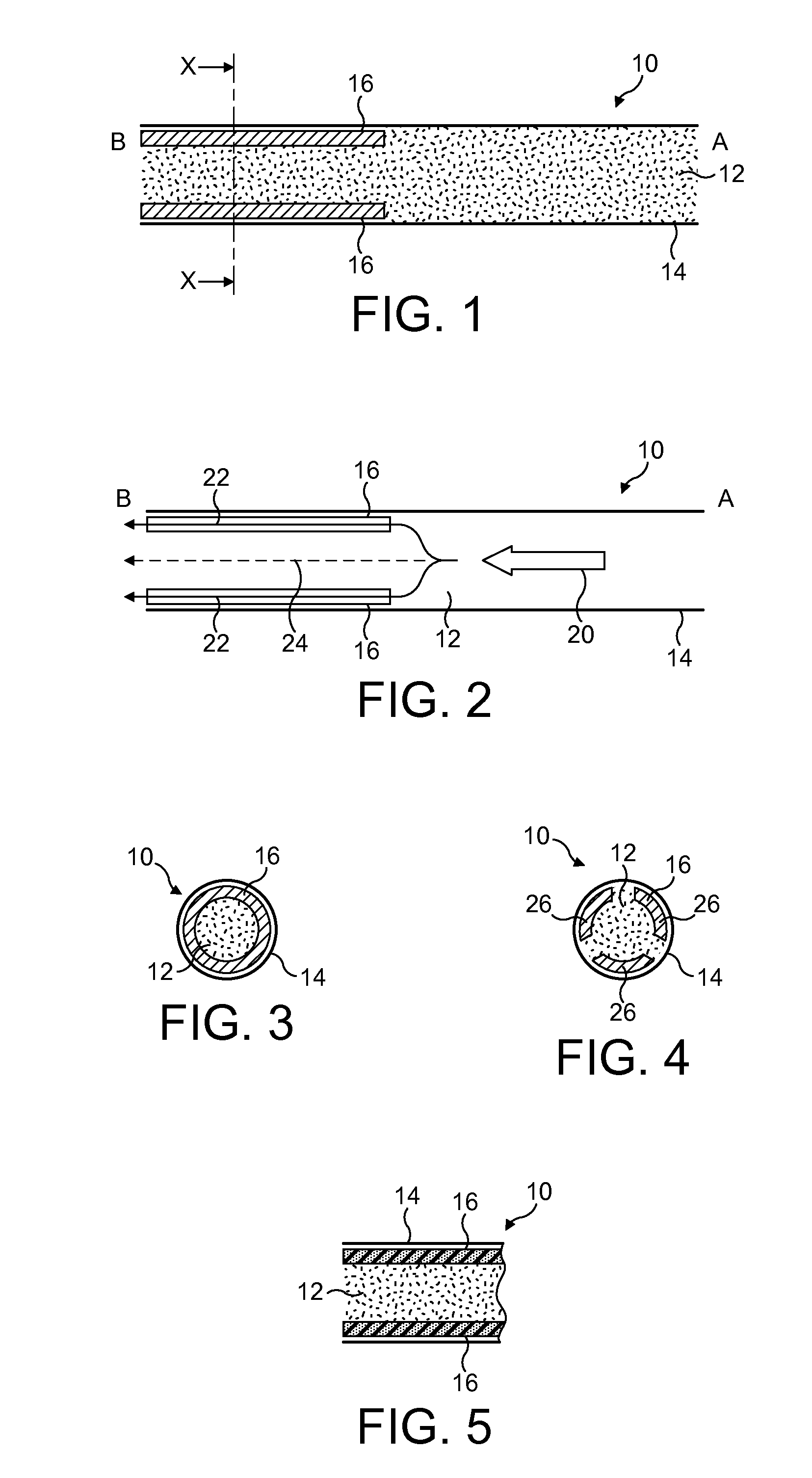

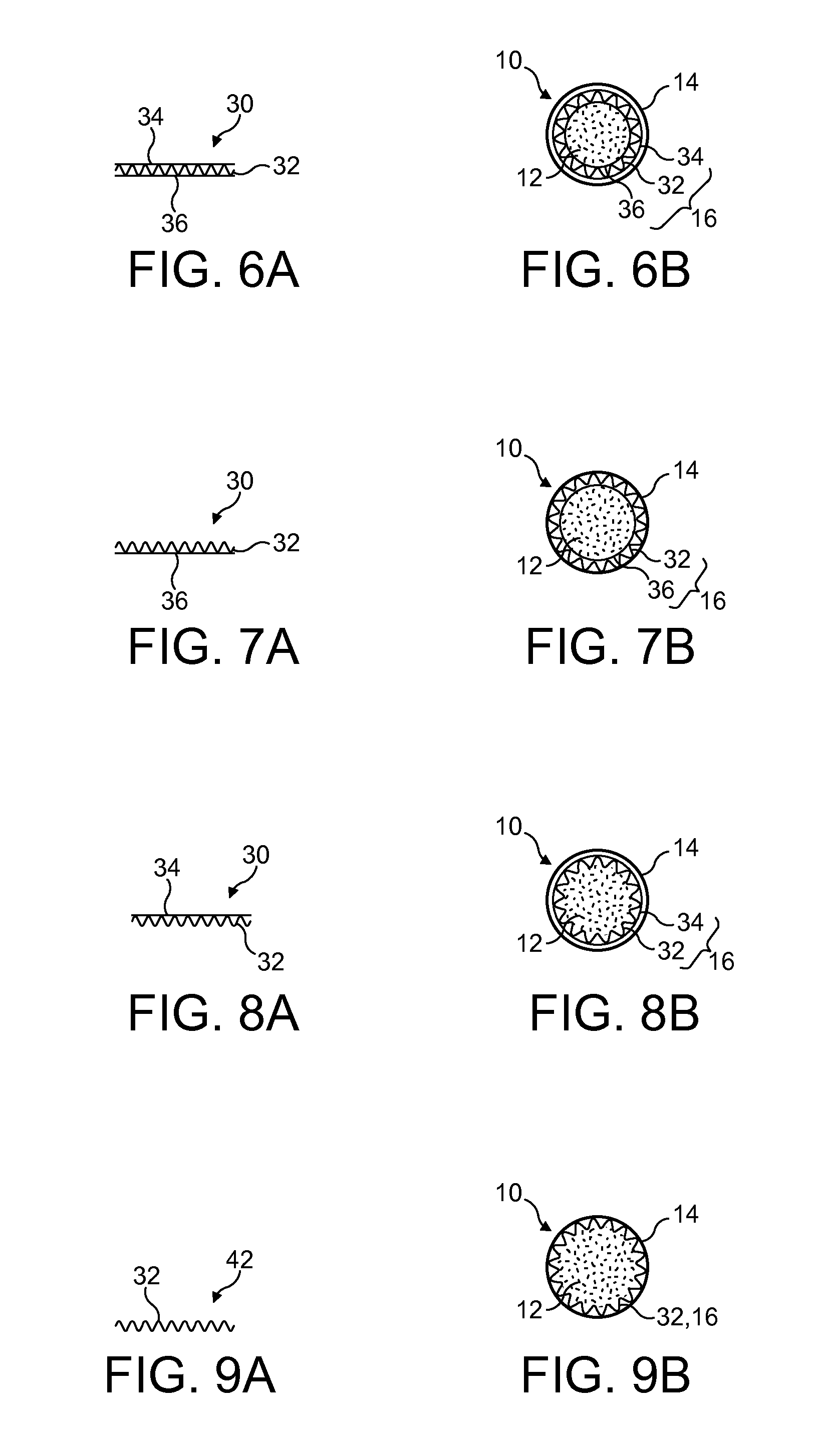

[0028]The present invention aims to provide a smoking article such as a cigarette that delivers smoke to the smoker with improved efficiency for a first portion of the smoking article, and also generates less smoke than a conventional smoking article from all or part of the remainder of the smoking article. To address this, a patch of material that allows a more free passage of smoke therethrough than does the tobacco of the smoking article is positioned under part of the outer wrapping paper of the smoking article.

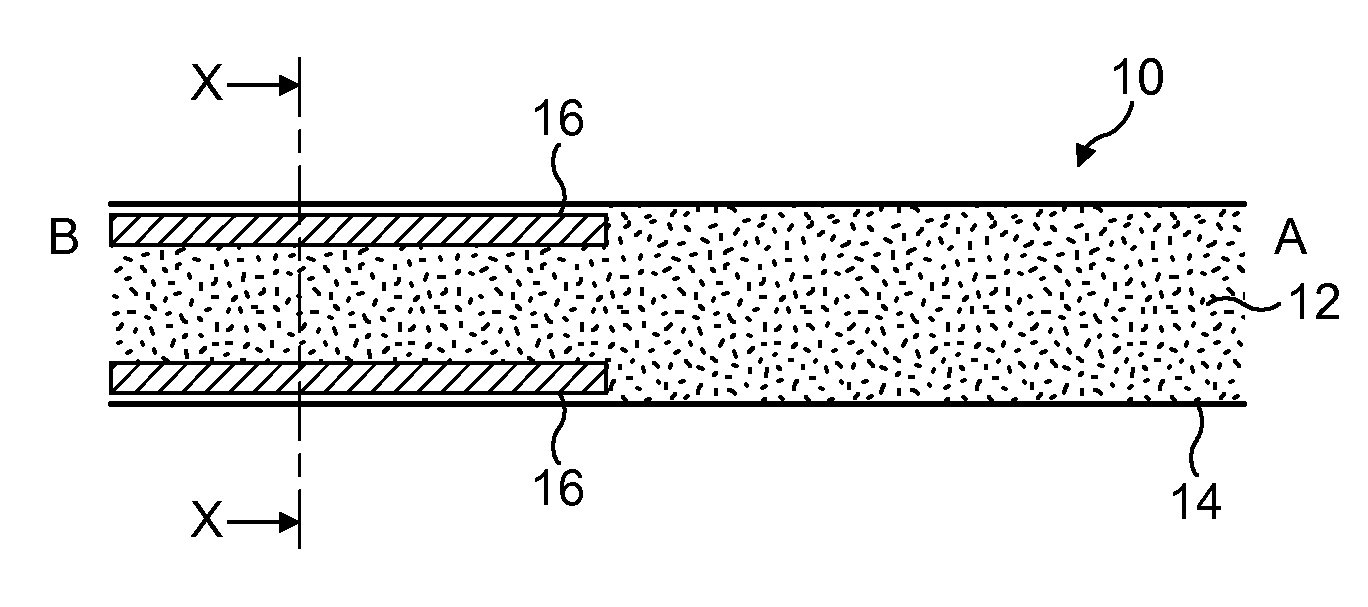

[0029]FIG. 1 shows a longitudinal cross-sectional view through a smoking article according to an embodiment of the invention. The smoking article 10 comprises, in the conventional manner, a cylinder or rod of tobacco 12 that is encircled or encased in a paper wrapper 14 (cigarette paper) that forms a tube around the tobacco 14. The smoking article has a first end A that is intended to be lit, and a second end B that is received in the mouth of the smoker. Again convention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com