Photovoltaic unit comprising a matrix of frameless solar modules

a solar module and photovoltaic technology, applied in photovoltaics, heat collector mounting/support, sustainable buildings, etc., can solve the problem of inability to simple uninstall solar modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Embodiments of the photovoltaic unit according to the invention with a connecting element, which protects against lifting off, between module and substrate rails are explained in more detail in the following on the basis of the schematic figures for further understanding of the invention. In the figures:

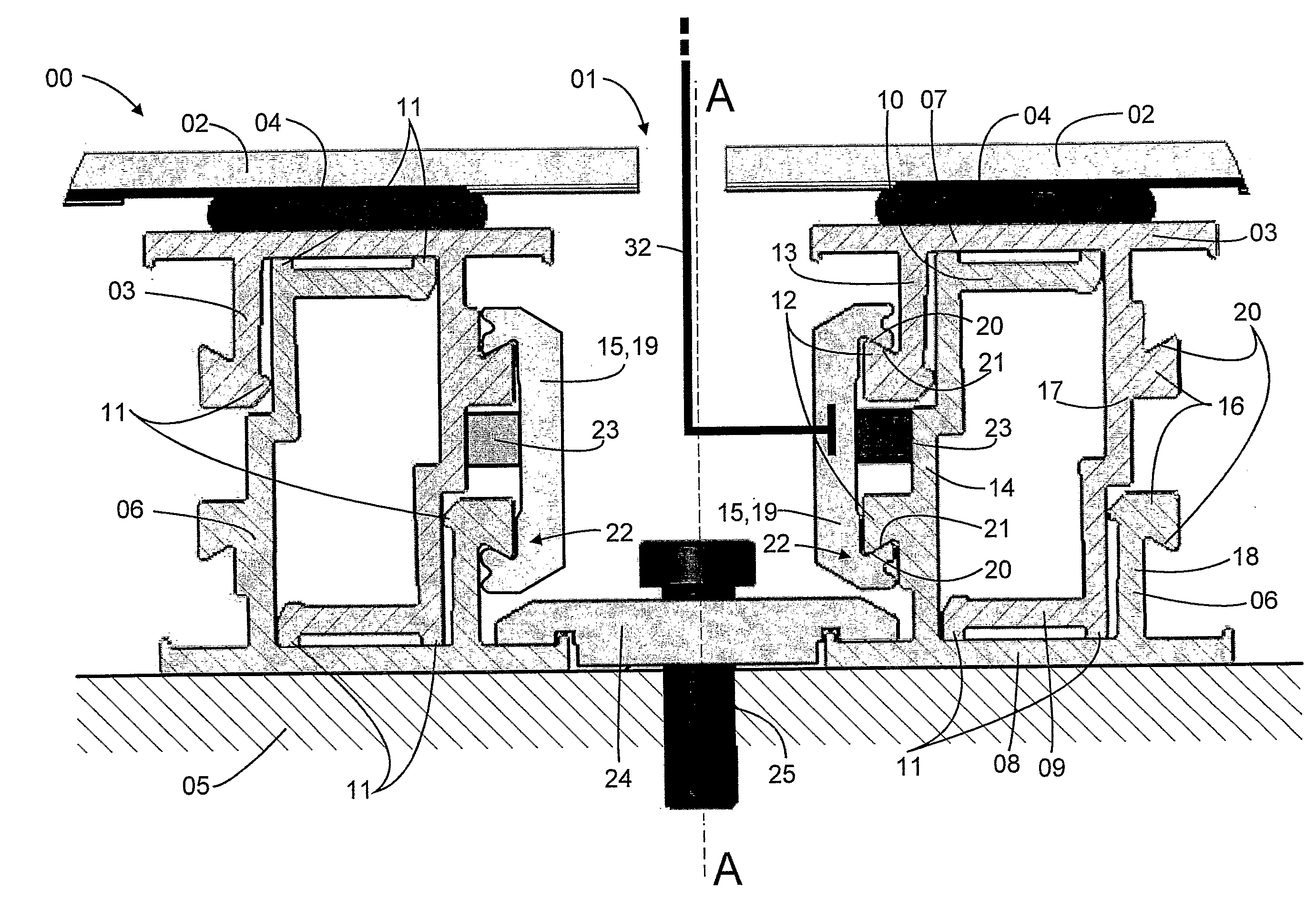

[0016]FIG. 1 shows the cross section of the photovoltaic unit according to the invention in the region of the spacer gap between two solar modules;

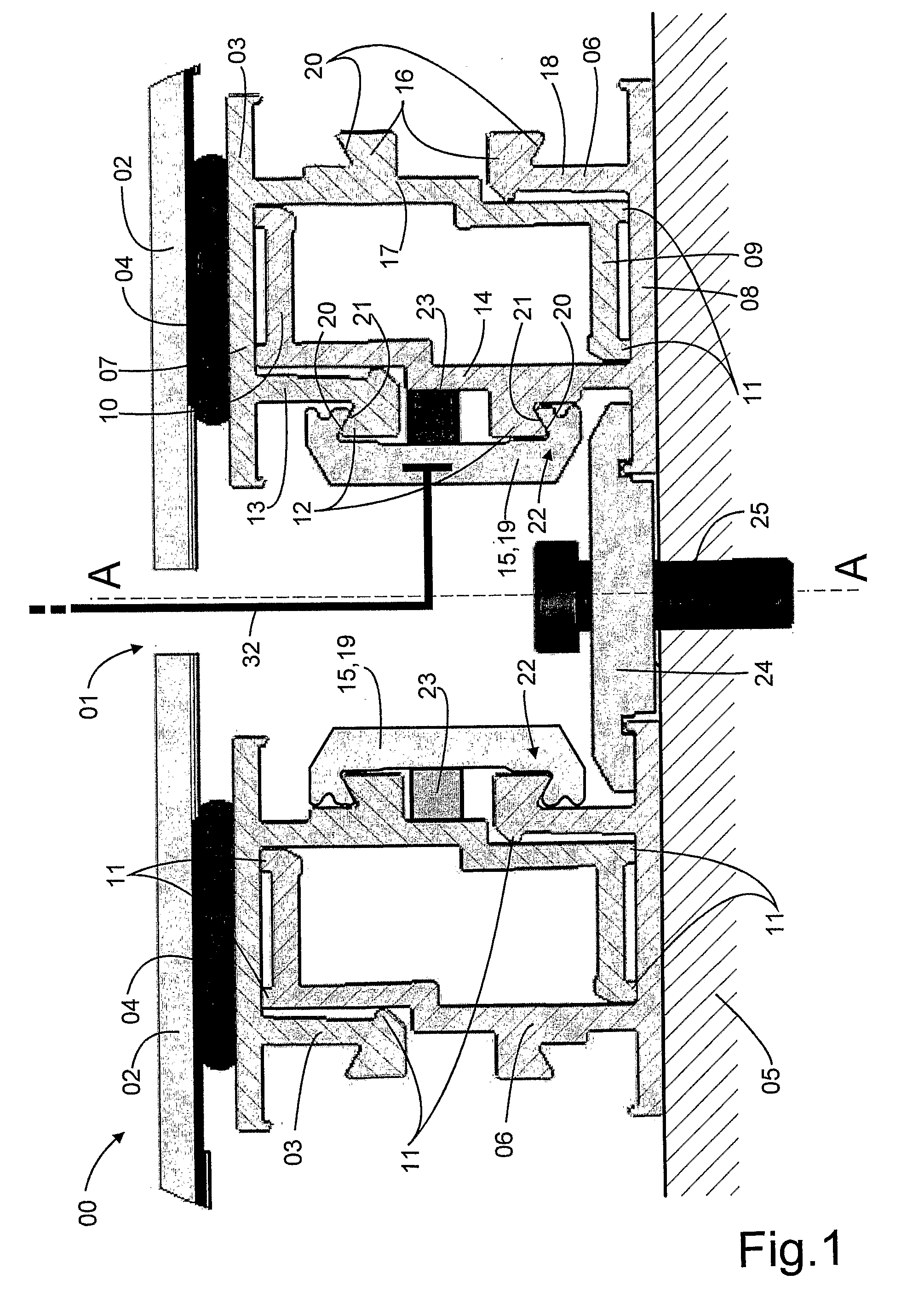

[0017]FIG. 2 shows a sectional representation onto a solar module in the region of the spacer gap;

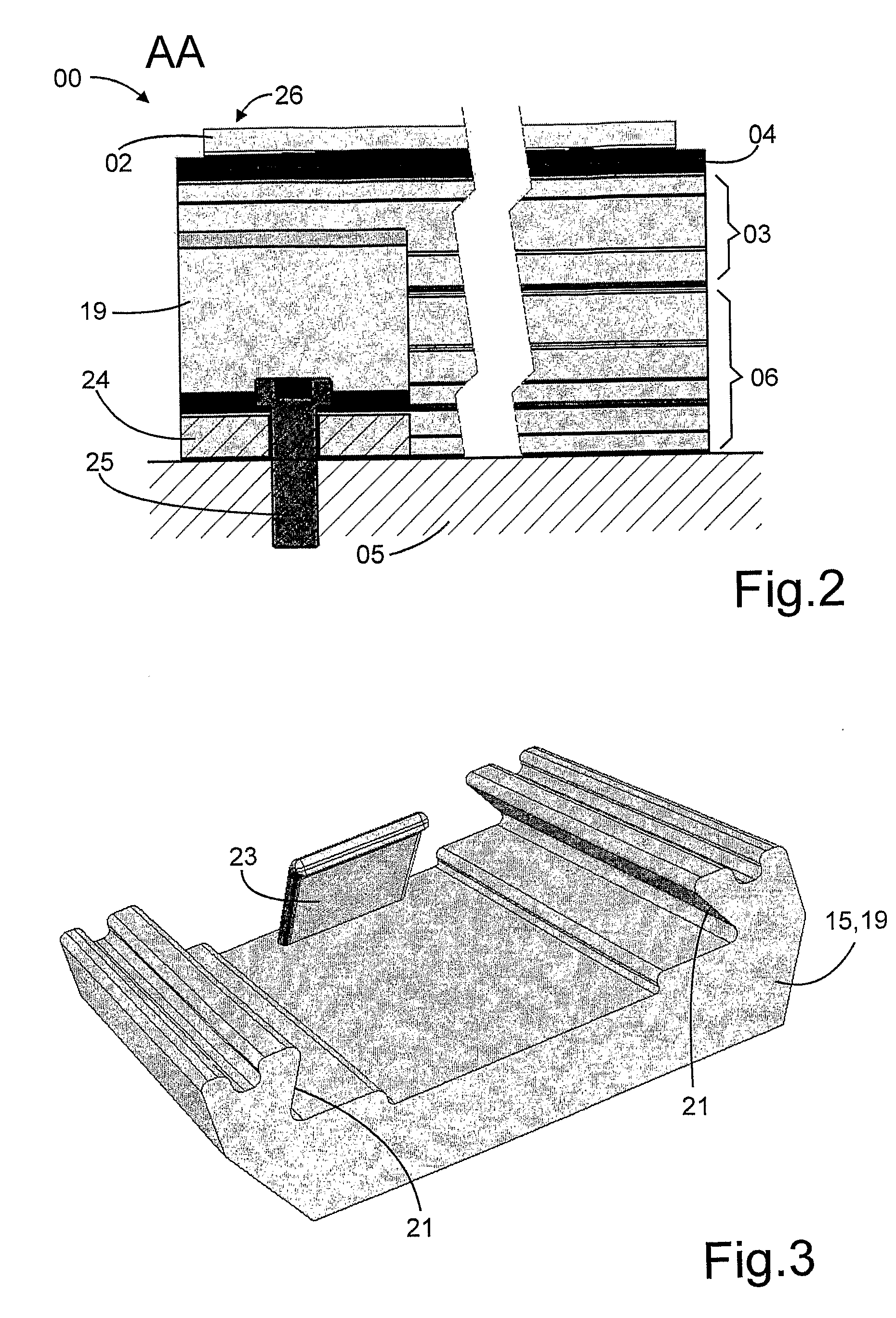

[0018]FIG. 3 shows a slider in detail; and

[0019]FIG. 4 shows two alternative constructions of sliders.

[0020]FIG. 1 shows a detail from a photovoltaic unit 00 according to the invention in cross section in the region of a spacer gap 01 between two frameless rectangular solar modules 02 (shown cut away from the side), which are arranged in a regular matrix, so that a harmonic undisturbed appearance of the photovoltaic unit results. A modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com