Greenhouse temperature and humidity control system and method thereof

A humidity control system and shed temperature technology, which are applied in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of inability to efficiently determine the expired state of the dehumidifier, lower fitting accuracy, and replacement. Not easy and other problems, to prevent the inflow of moisture, reduce consumption, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

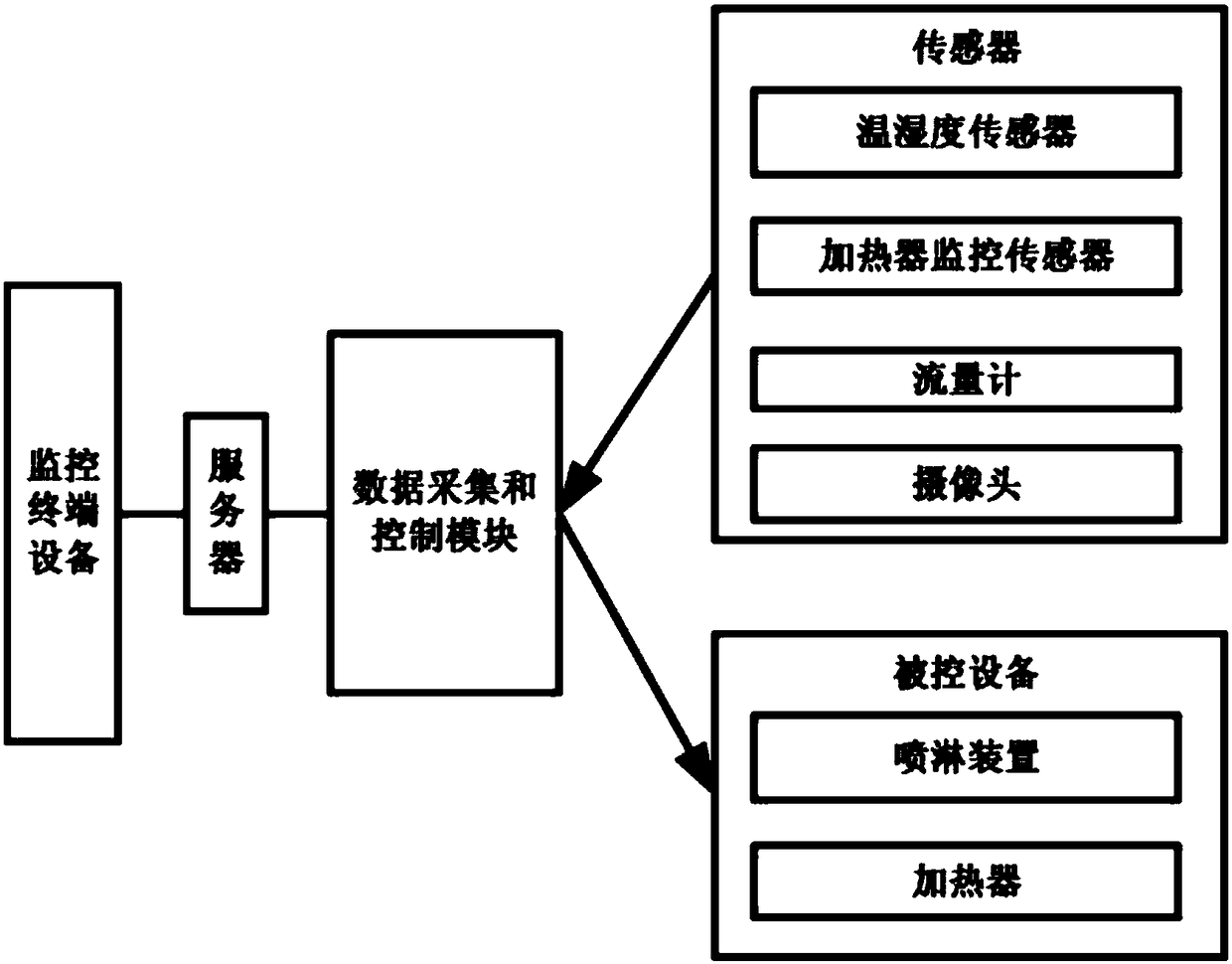

[0079] Such as Figure 1-Figure 8 As shown, the greenhouse temperature and humidity control system includes sensors and controlled equipment, and the sensors and controlled equipment are connected to the microcontroller; the microcontroller is connected to the server; the monitoring terminal equipment and the server exchange information through wired or wireless methods.

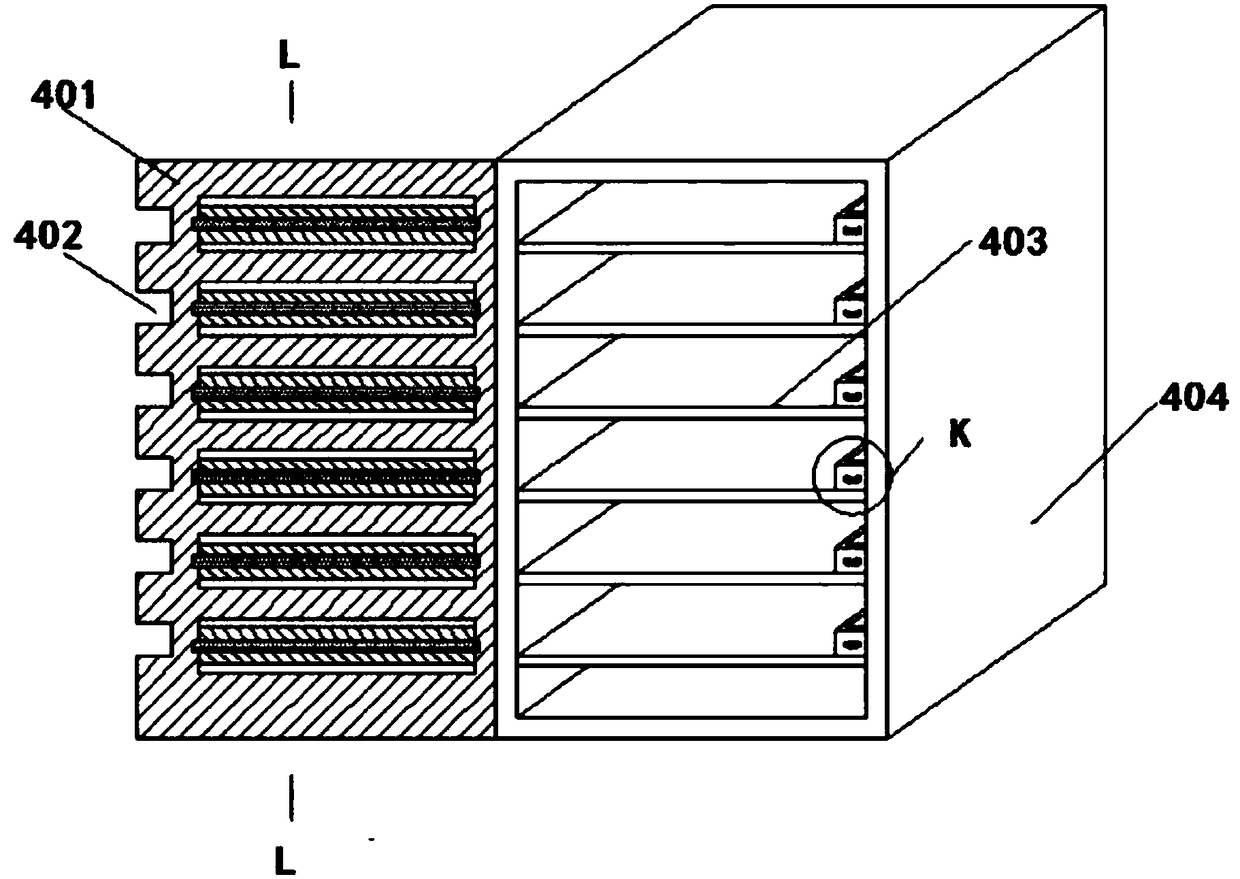

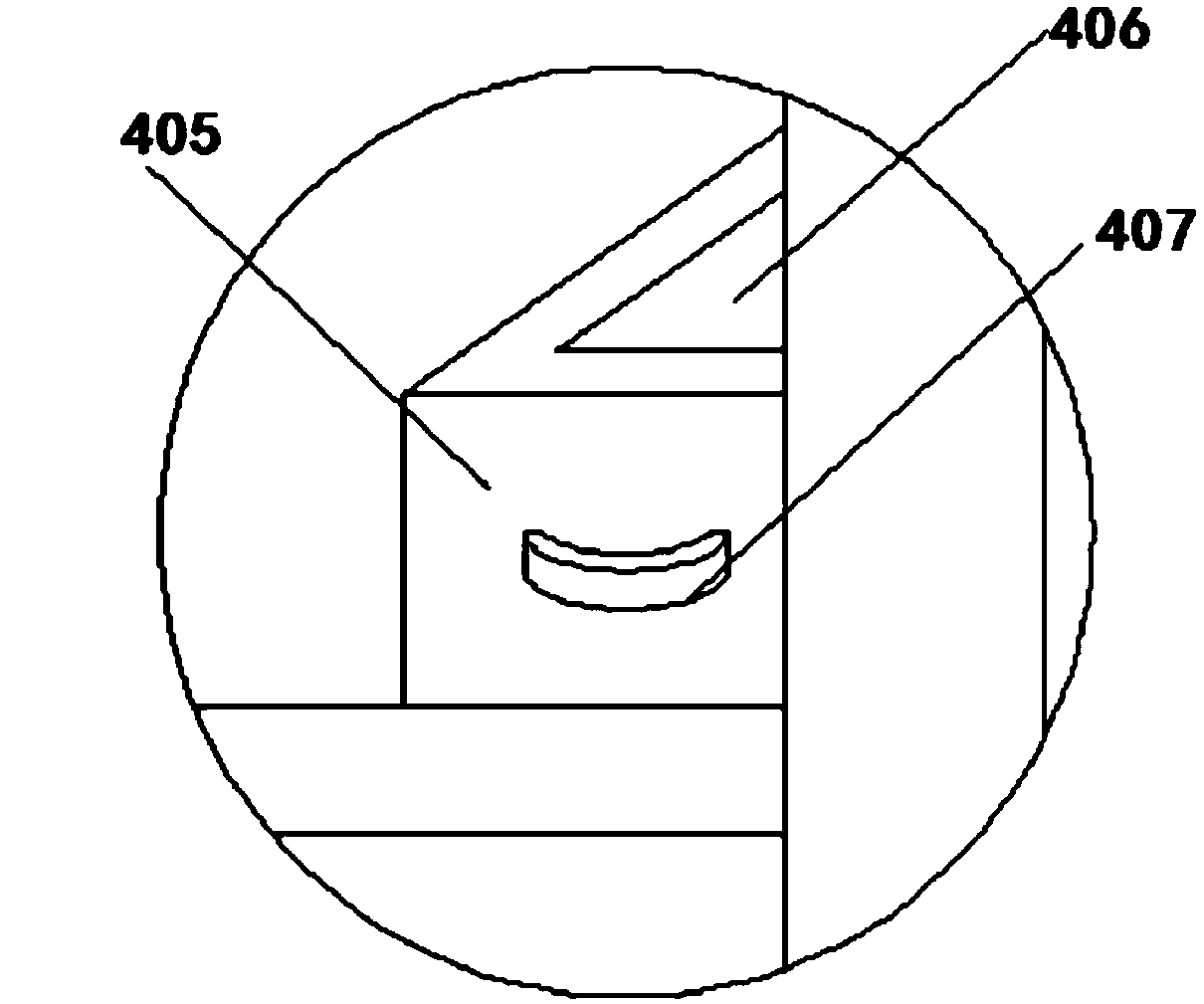

[0080] The server is often arranged in a server case, and the server case includes a hollow cuboid casing 404 and a cover plate 401 pivotally connected to the hollow cuboid casing 404. The cover plate 401 is provided with a groove for guiding the upper wall. The cuboid-shaped member 405 of the road extends into the guide channel 1 402 in the hollow cuboid-shaped housing 404, and the upper wall of the cuboid-shaped member 405 with a ditch is provided with a ditch for storing desiccant,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com