Refrigeration cycle apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

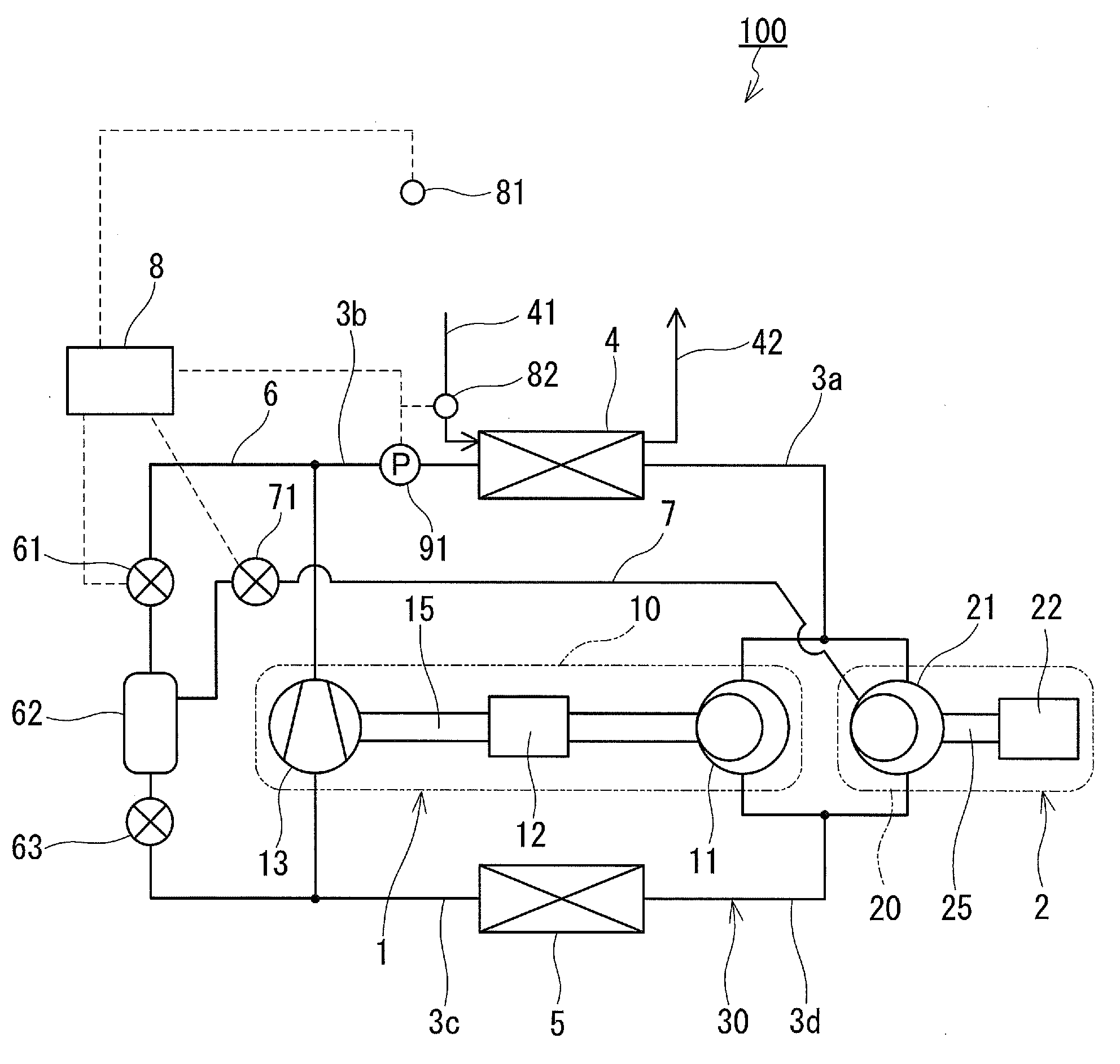

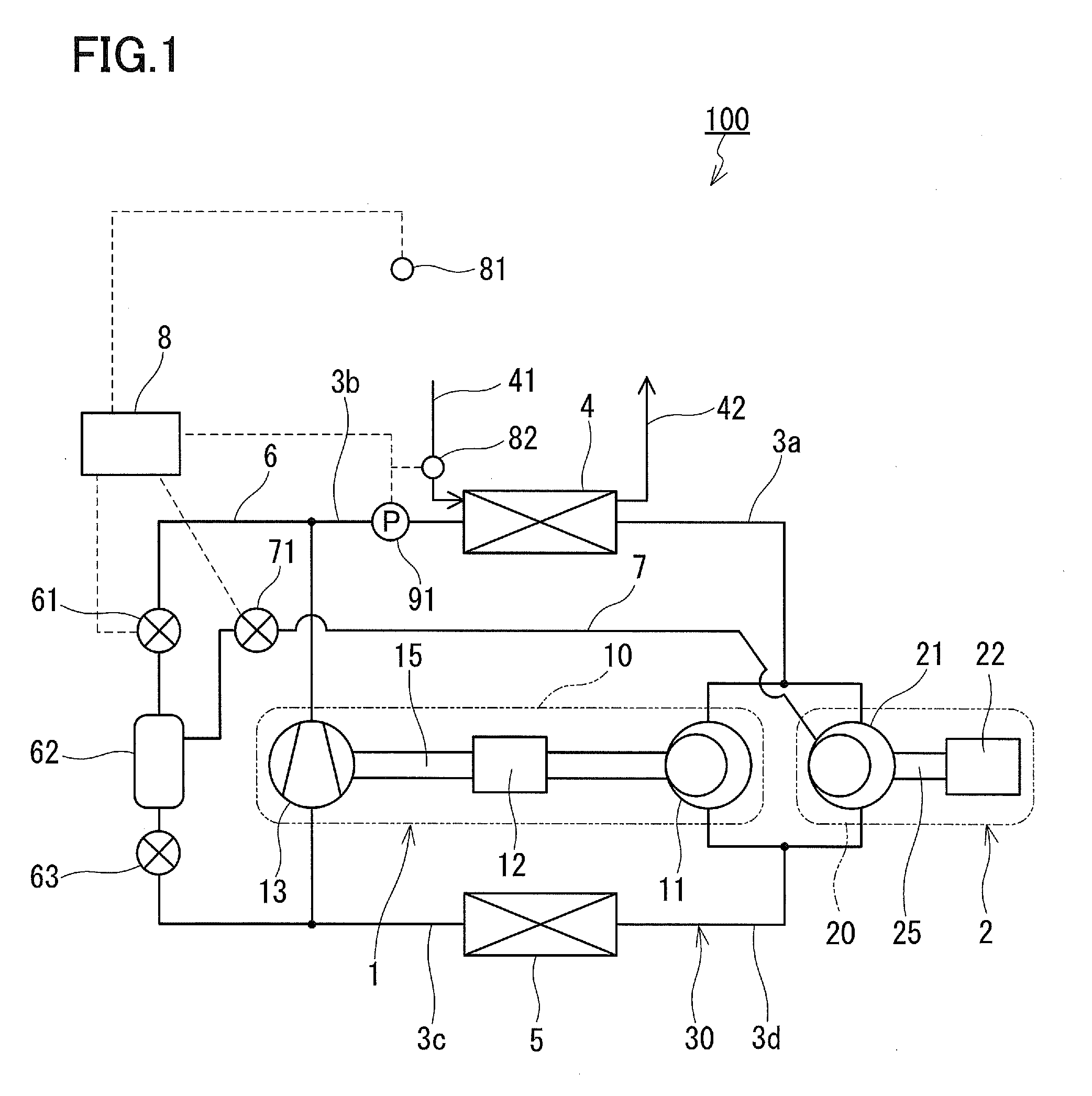

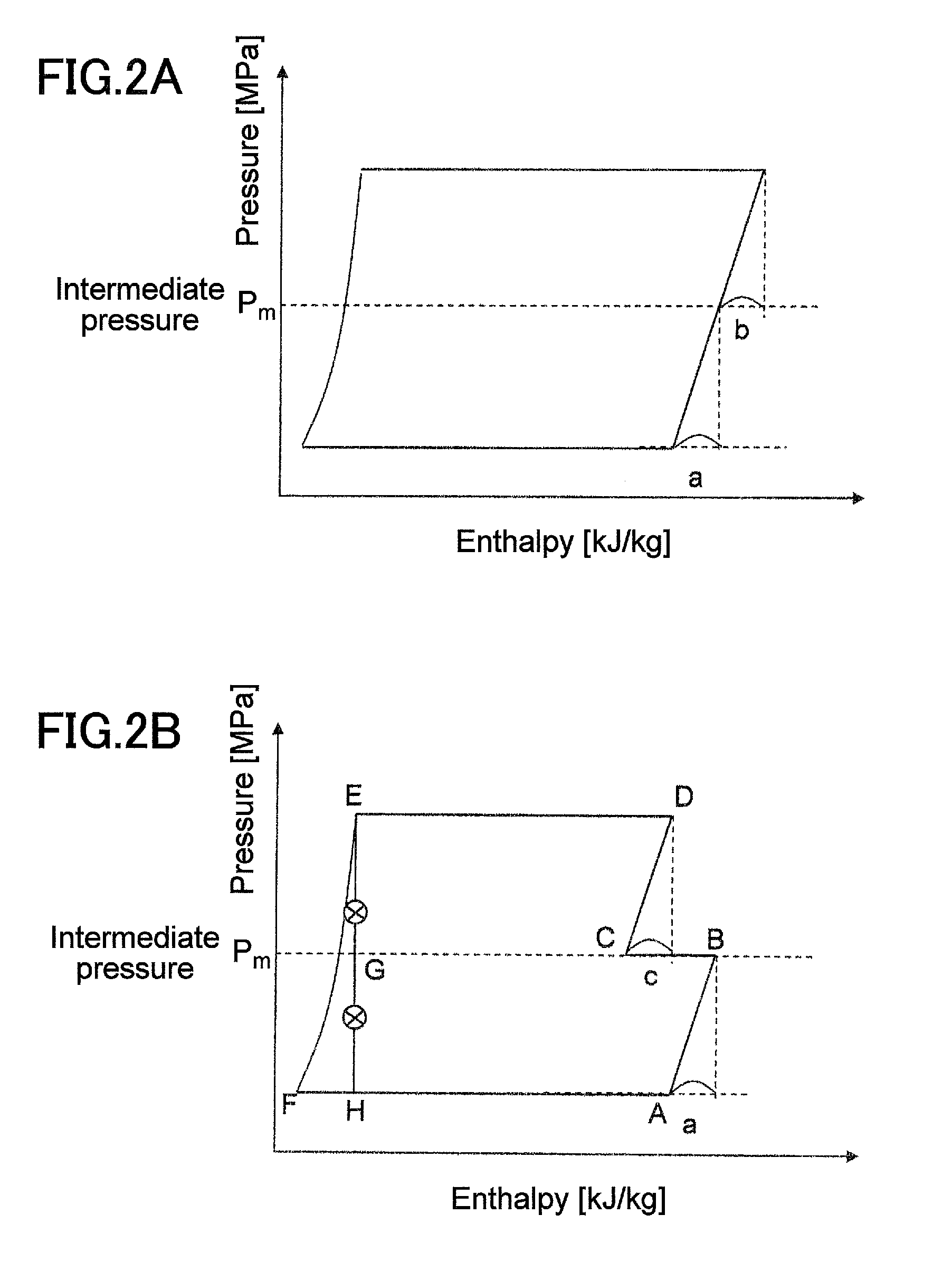

Method used

Image

Examples

modified example

[0048]Although the fixed throttle is used as the second flow control valve 63 in the above-mentioned embodiment, it also is possible to use an expansion valve as the second flow control valve 63. In this case, a second pressure sensor (a second pressure detecting means) 92 for detecting the pressure in the gas-liquid separator 62 may be provided as in a refrigeration cycle apparatus 100A according to a modified example shown in FIG. 4, and the opening of the second flow control valve 63 may be adjusted by the controller 8 so that the intermediate pressure Pm detected by the pressure sensor 92 becomes equal to or higher than the specified pressure Pb. In the example shown in FIG. 4, the pressure sensor 92 is provided to the bypass passage 6, between the first flow control valve 61 and the gas-liquid separator 62.

[0049]Or, instead of the pressure sensor 92, a refrigerant temperature sensor 84 for detecting the temperature of the refrigerant in the gas-liquid separator 62 may be provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com