Flow system for bidets

a flow system and flow valve technology, applied in multiple way valves, mechanical equipment, physical therapy, etc., can solve the problems of unnecessarily increasing the storage capacity of hot water tanks, waste of hot water, and unnecessary increase of hot water storage capacity b>12/b>, so as to improve the use efficiency of hot water, enhance washing performance, and improve the effect of sterilization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Hereinafter, exemplary embodiments of the present invention will be described in detail, with reference to the accompanying drawings.

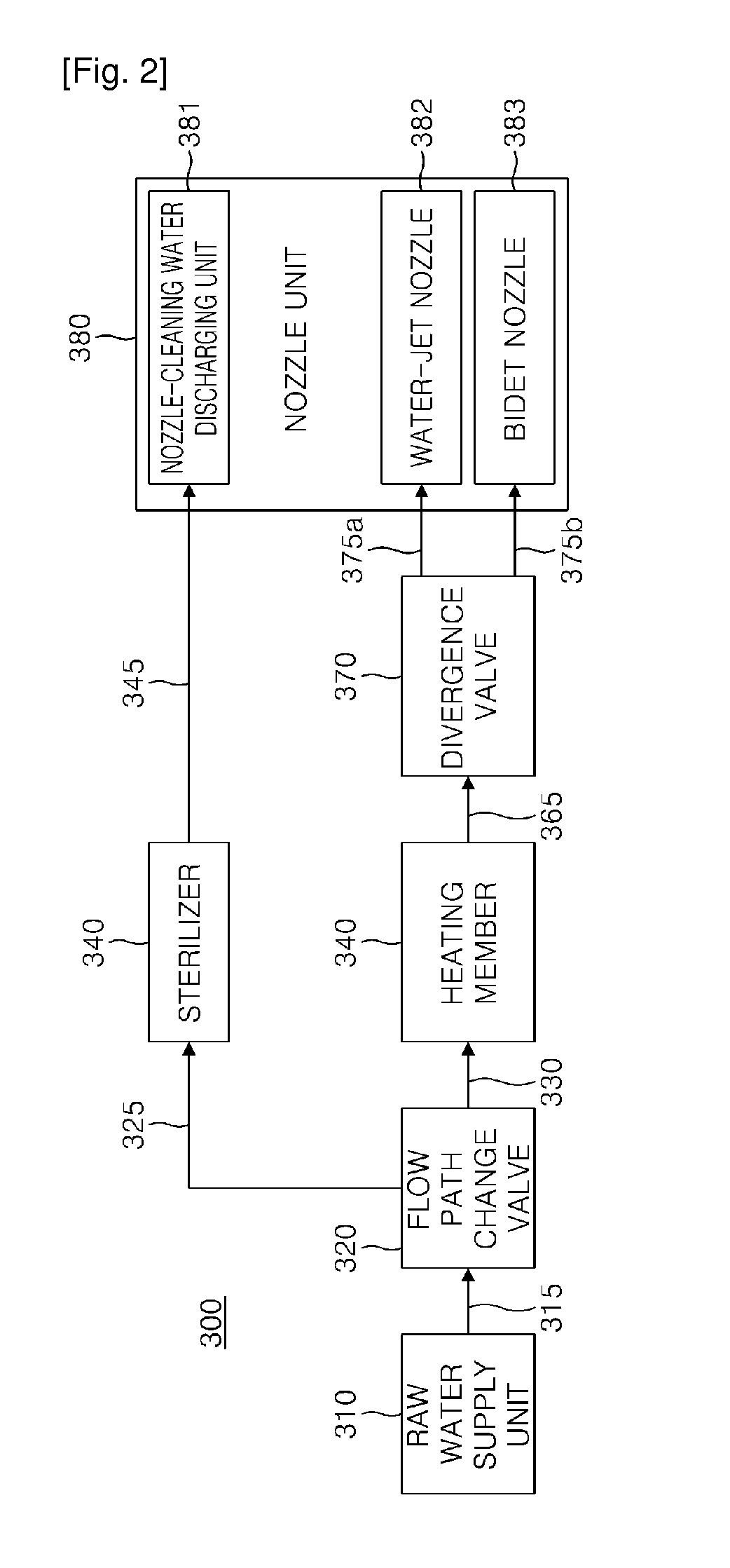

[0042]FIG. 2 is a configuration diagram illustrating a flow system for bidets according to one exemplary embodiment of the present invention.

[0043]Referring to FIG. 2, the flow system 300 for bidets according to one exemplary embodiment of the present invention includes a flow path change valve 320, a sterilizer 340, a heating member 360, a divergence valve 370 and a nozzle unit 380.

[0044]Raw water, which is fed from a raw water supply unit 310 provided with valves to control the supply of the raw water, flows into the flow path change valve 320 through a raw water input flow path 315. Then, room-temperature raw water from the raw water supply unit 310 flows into the flow path change valve 320.

[0045]Also, the flow path change valve 320 changes flow paths so that the introduced water can flow through at least one flow path out of a plurality of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com