Method for operating an oil supply and controller

a controller and oil supply technology, applied in the direction of mechanical equipment, machines/engines, instruments, etc., can solve the problems of high fuel consumption and co2/sub>-emissions of combustion engines, and achieve the effects of reducing fuel consumption and co2-emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The following detailed description is merely exemplary in nature and is not intended to limit application and uses. Furthermore, there is no intention to be bound by any theory presented in the preceding background or summary or the following detailed description.

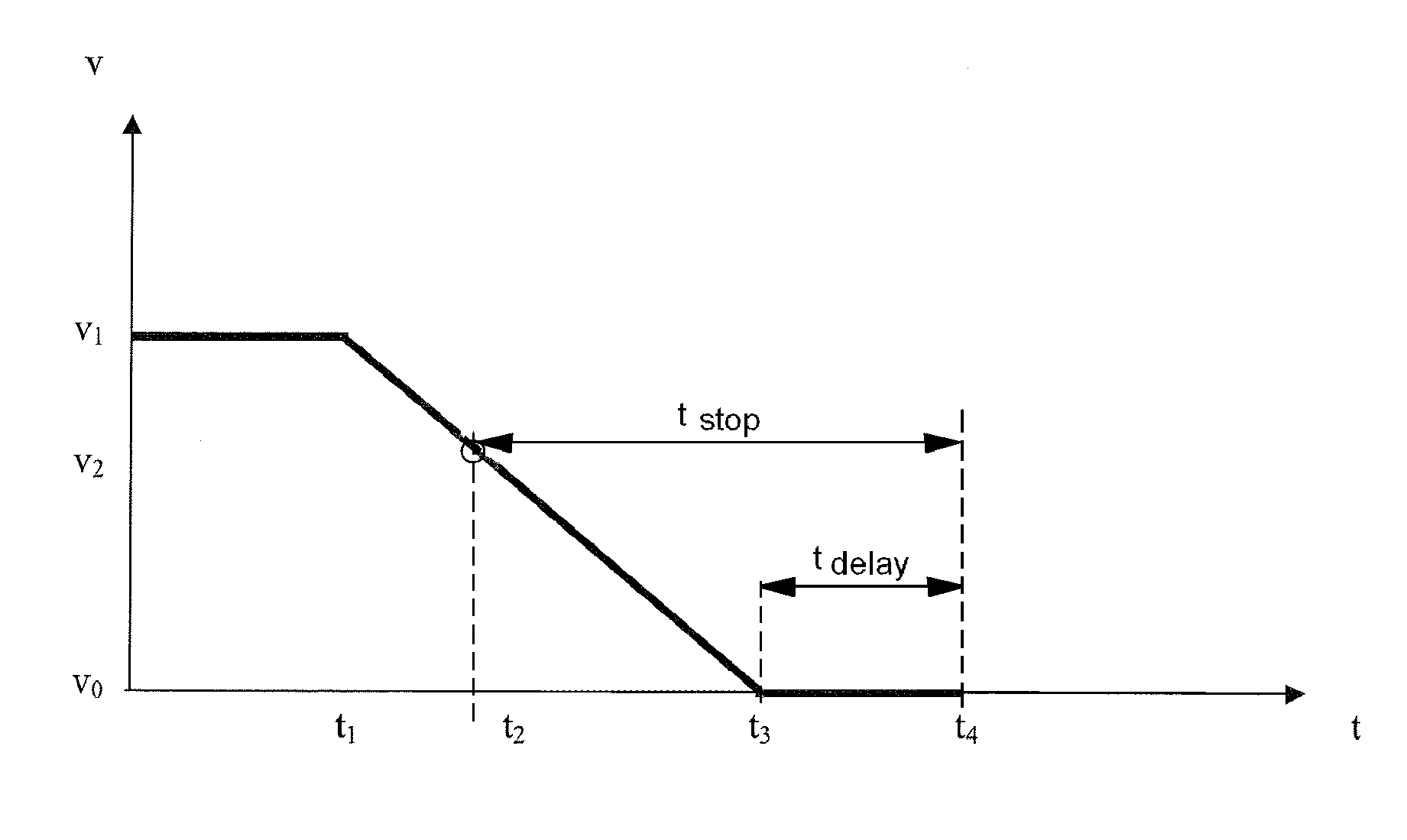

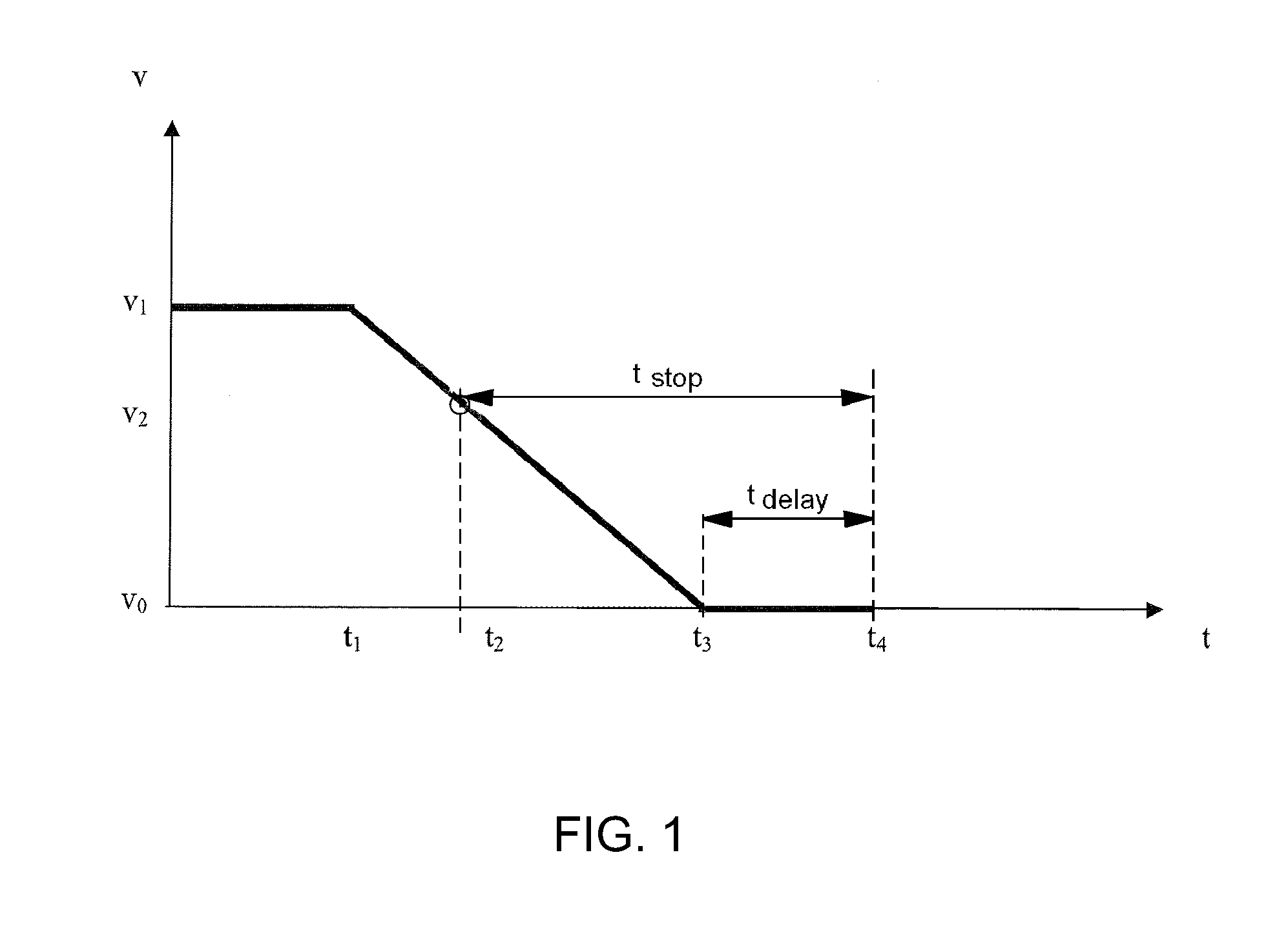

As illustrated in FIG. 1 a motor vehicle may comprise a vehicle speed v1 and can be decelerated at a time t1. Under the assumption of a constant deceleration the vehicle speed decreases until at a time t3 a vehicle speed of v0=0 km / h is reached. Usually it takes a period of time at zero vehicle speed v0 until a start / stop-automatic of the motor vehicle initiates an automatic stop of a combustion engine of the motor vehicle at a time t4.

From time t1 on the method monitors whether a minimum oil pressure for an oil supply system will be provided at the time t4. When for example the actual time is t2 it is calculated based on the actual vehicle speed v2 and the actual amount of the deceleration a={dot over (ν)}2 a stop-time tst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com