Modular thermal water solar panel system

a solar panel and module technology, applied in solar heat collectors, solar heat collectors for particular environments, solar panels with working fluids, etc., can solve the problems of increasing the initial installation and future expansion costs of such systems, requiring professional expertise, and not being able to connect multiple instances of the same solar panel assembly into a single array in modular fashion, so as to facilitate the connection of multiple instances, increase the overall surface area used, and increase the overall system capacity. the effect of heating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

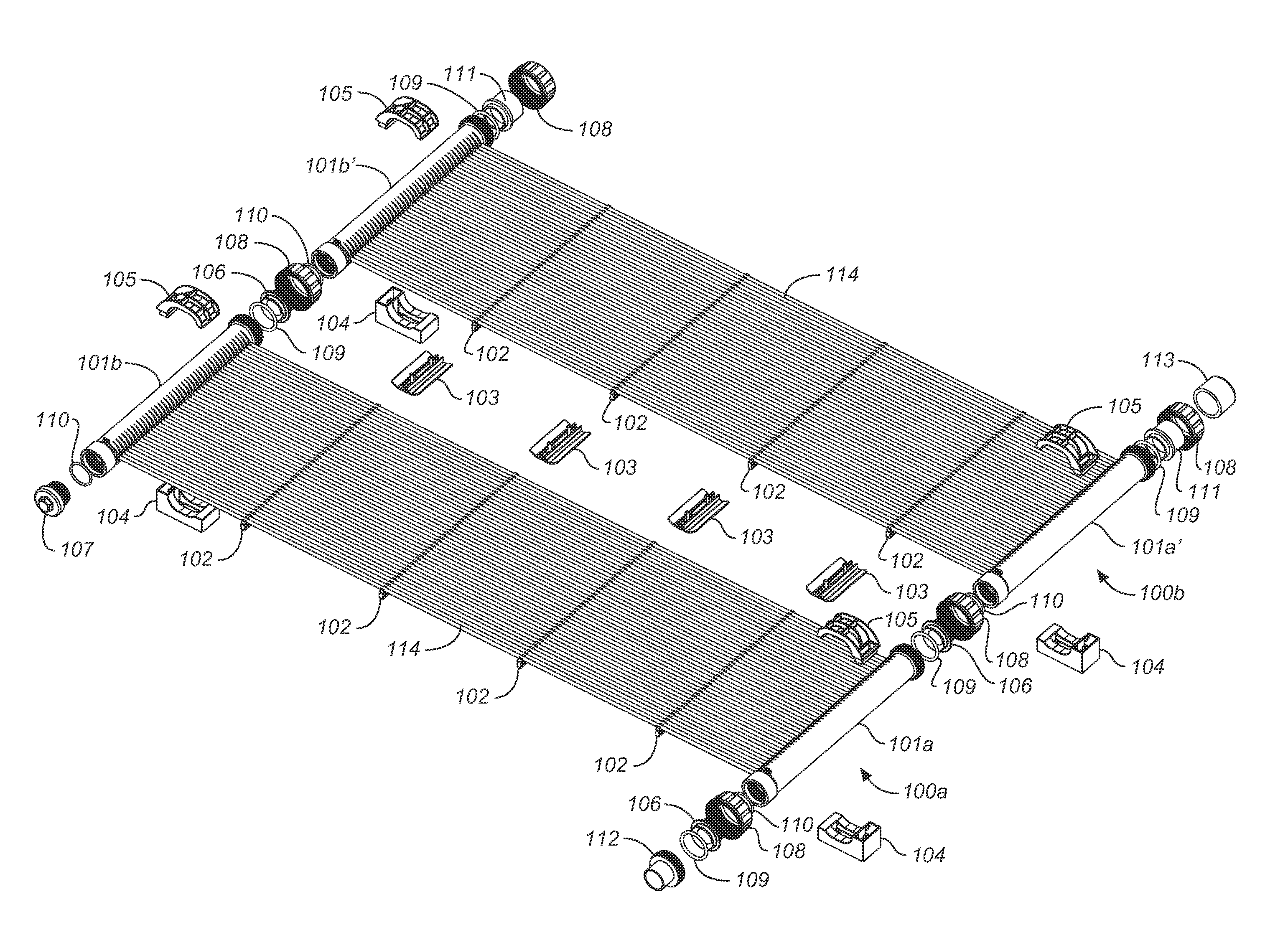

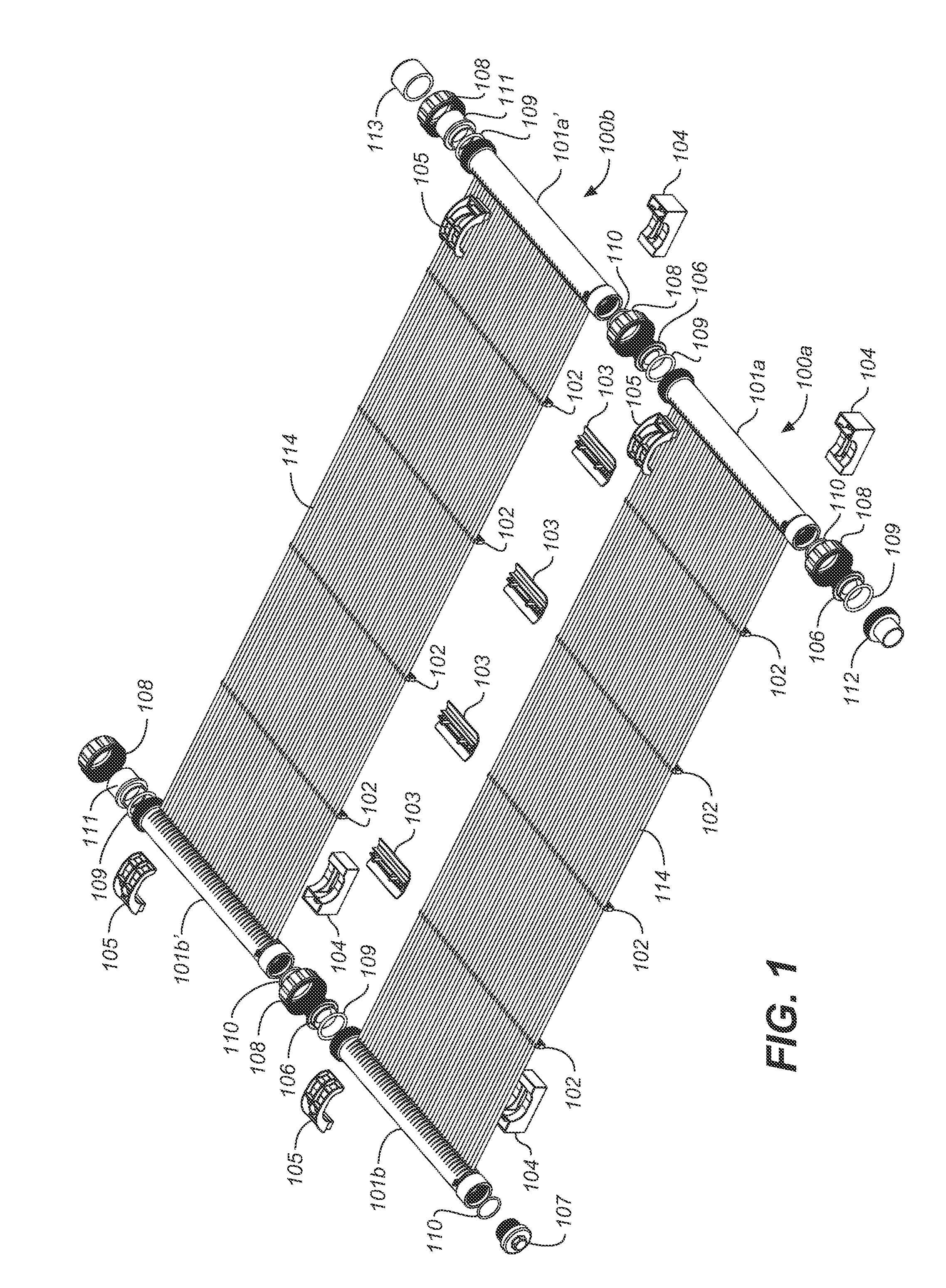

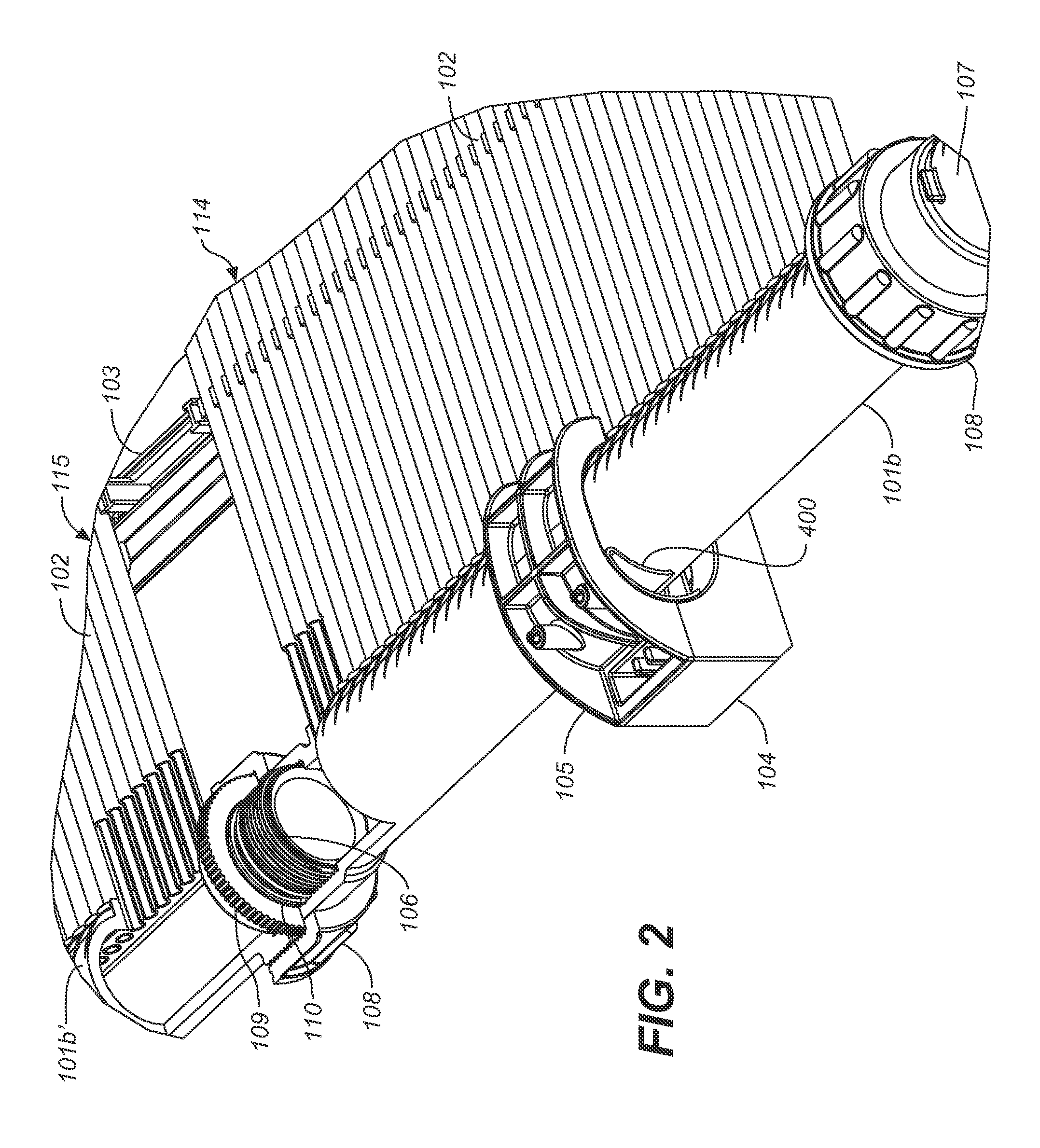

[0033]Referring now to FIG. 1, there is shown in an exploded perspective view the components comprising two instances (or modules) 100a, 100b, of the tube manifold assembly of the present invention. It can be seen that each one of a first and second tube manifold assembly 100a, 100b includes an array of small-diameter tubes, which is termed the thin tube array. Two such arrays 114, 115, are shown in this view, each showing the thin tubes disposed in substantially a single plane and connected at each end to a fluid port disposed on the interior side of each large tube manifold. This brings the thin tubes 102 of the thin tube arrays 114, 115 into fluid communication with each of two opposing large tube inlet and outlet manifolds 101a, 101b. The fluid ports are disposed in a generally linear row along each interior side of the large tube outlet and inlet manifolds. In a first embodiment, the large diameter tubes comprise, respectively, a large tube inlet manifold, 101a and 101a′, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com