Heat transfer device with functions of power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

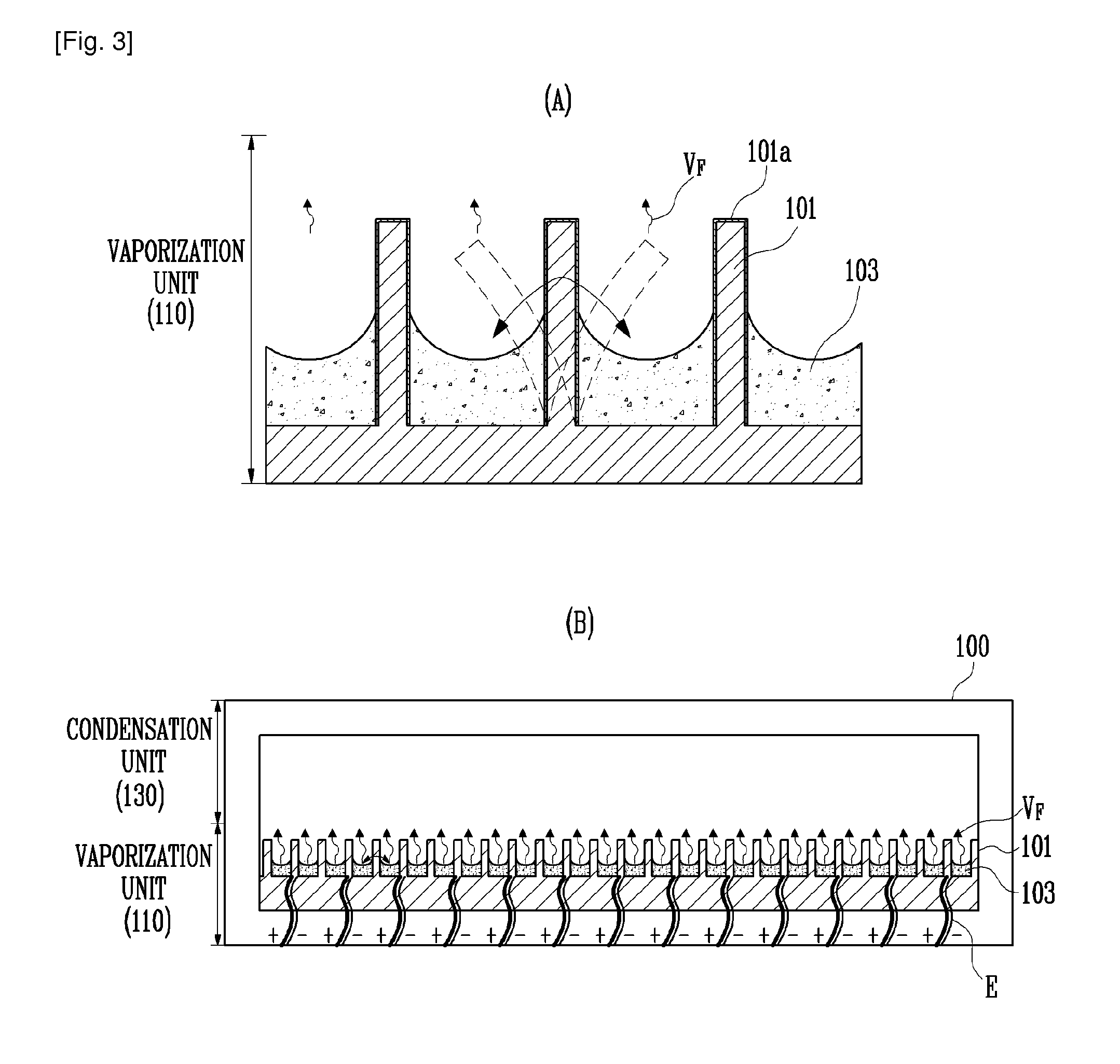

[0017]Hereinafter, an example embodiment of the present invention will be described in detail with reference to the accompanying drawings. However, it will be appreciated by those skilled in the art that various changes may be made to these example embodiments, and the scope of the present invention is not limited to the example embodiments. The example embodiments are provided to more clearly explain the present invention to those skilled in the art.

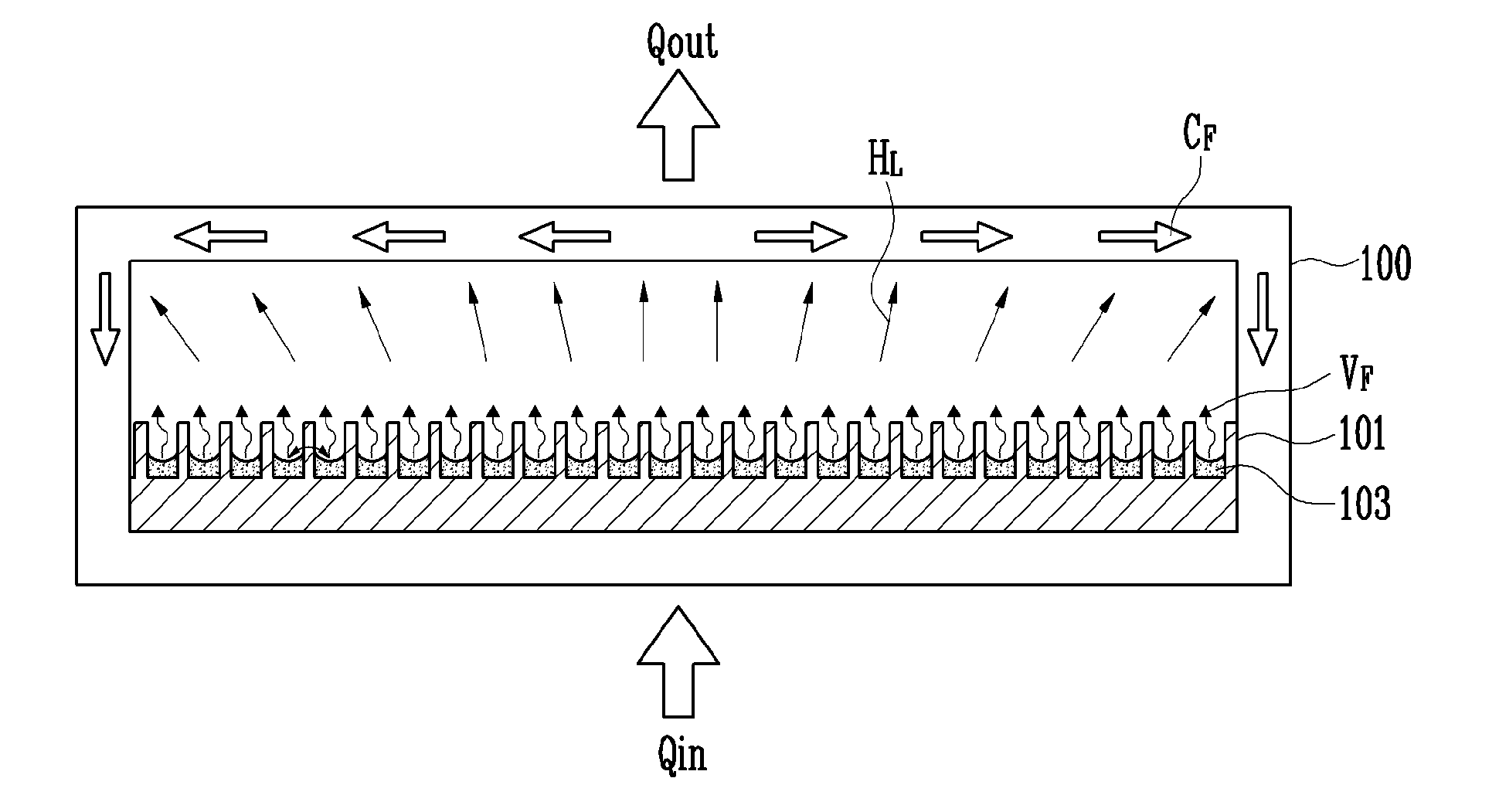

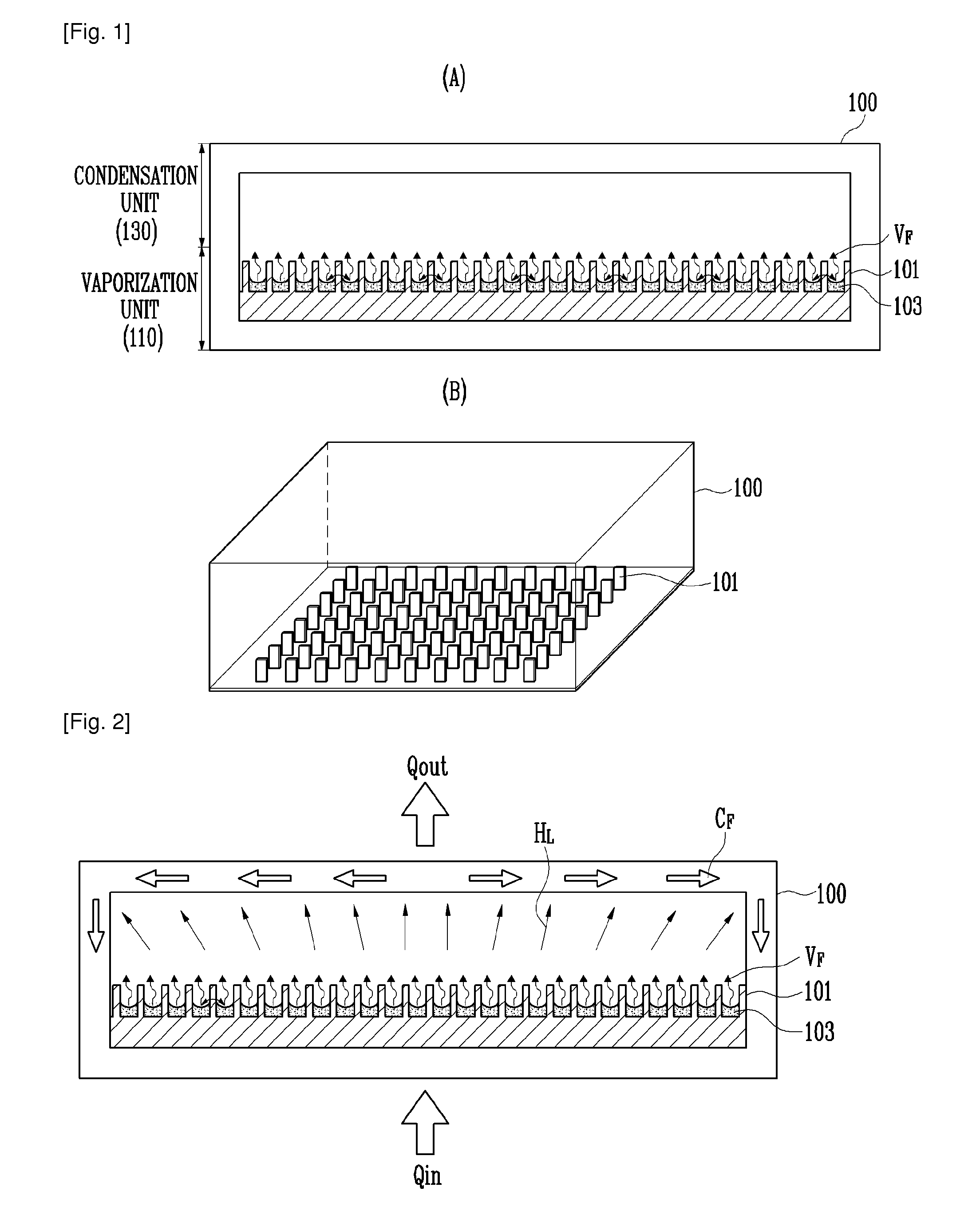

[0018]FIGS. 1A and 1B are schematic views of a heat transfer device capable of generating power according to the present invention. FIG. 2 is a diagram for explaining heat transfer operation of the heat transfer device according to the present invention.

[0019]Referring to FIGS. 1A and 1B, the heat transfer device 100 capable of generating power according to the present invention has an airtight structure of which the inner space is maintained in a vacuum state.

[0020]A working fluid 103 is injected into the heat transfer device 100 havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase | aaaaa | aaaaa |

| Piezoelectricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com