Exhaust gas diffuser

a technology diffuser, which is applied in the field of turbines, can solve the problems of one source of loss and turbulence generation of exhaust gas diffuser, and the loss incurred in this region can have significant impact on the performance and acoustic behavior of the total diffuser system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

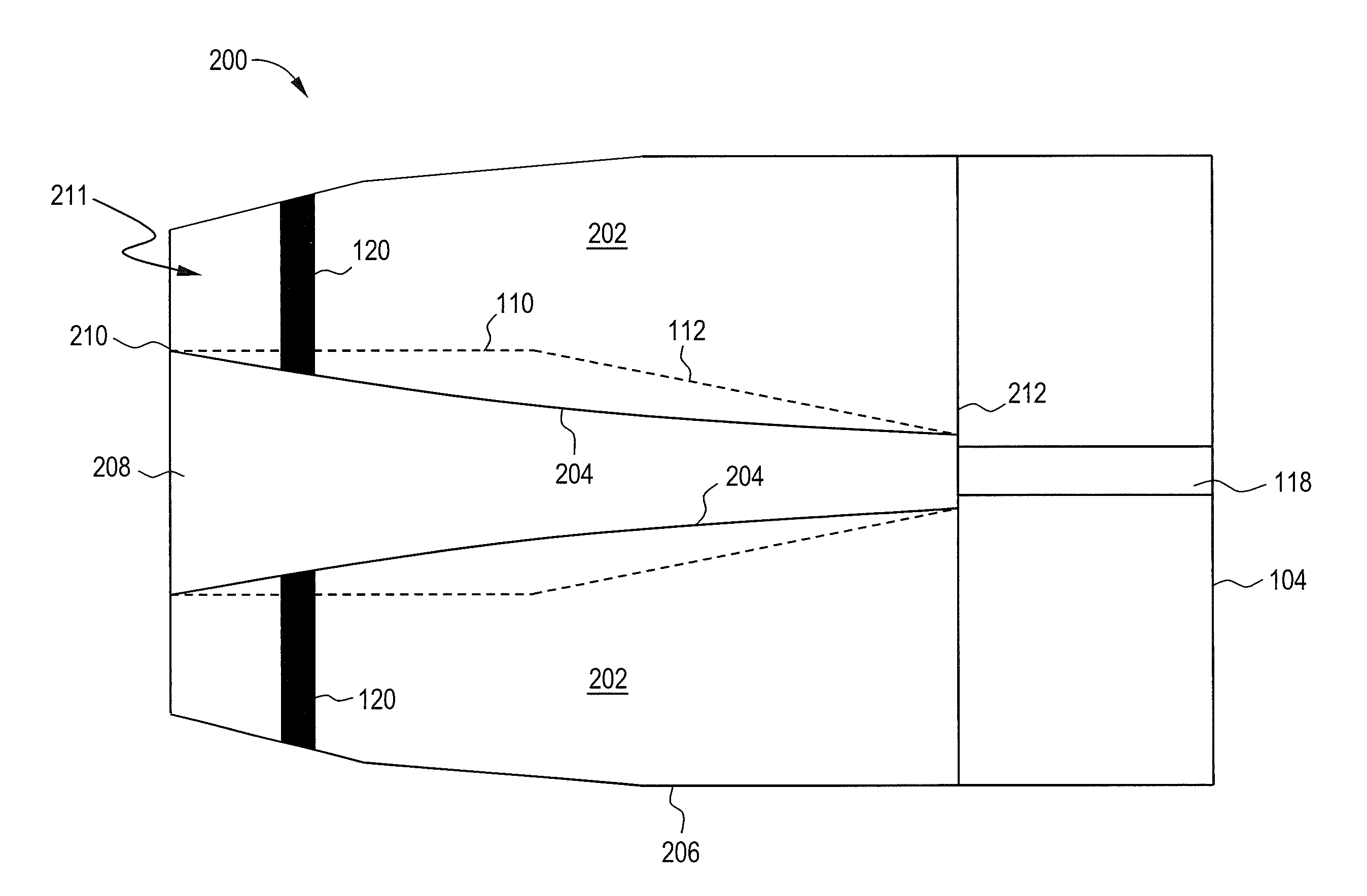

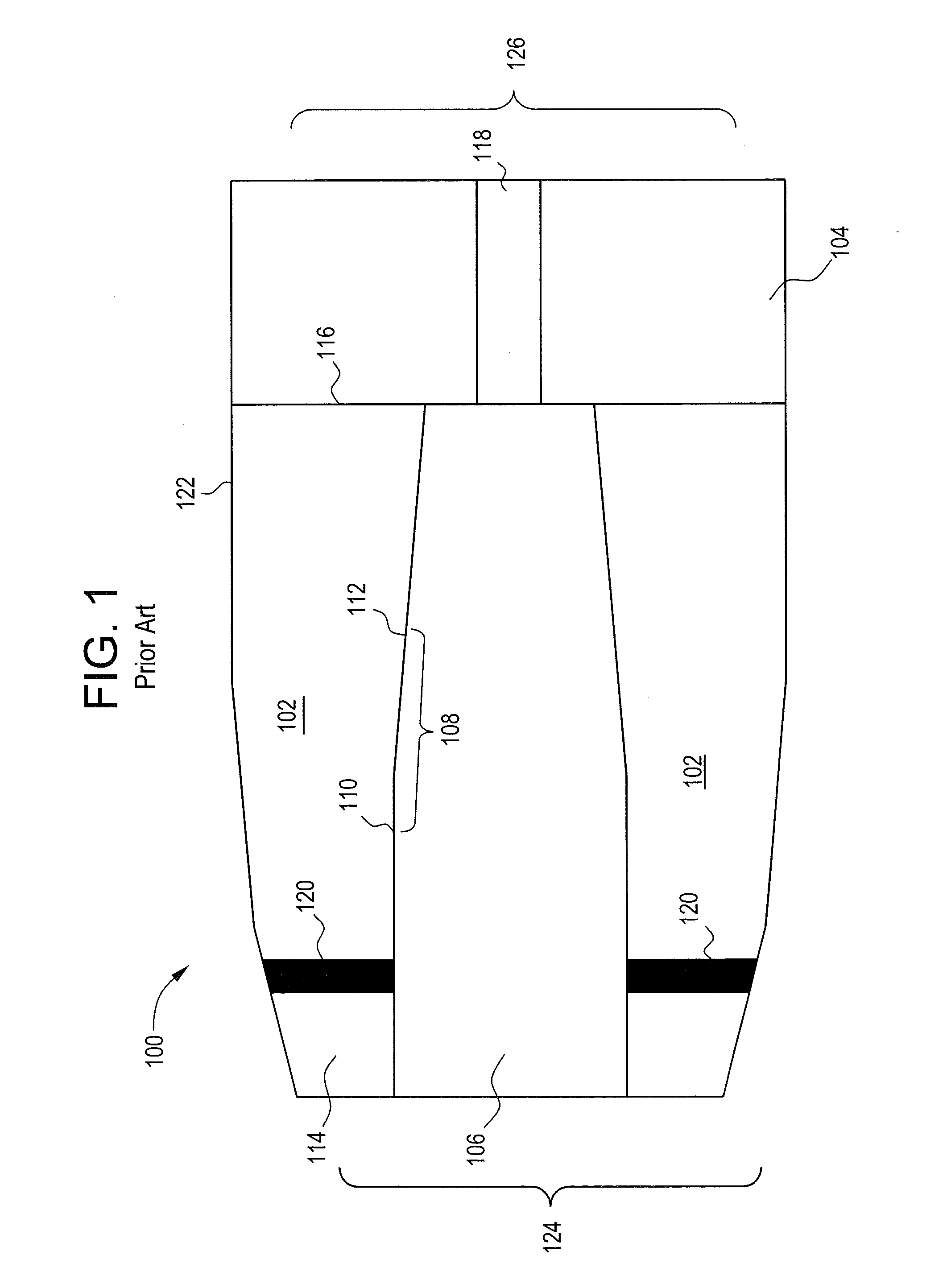

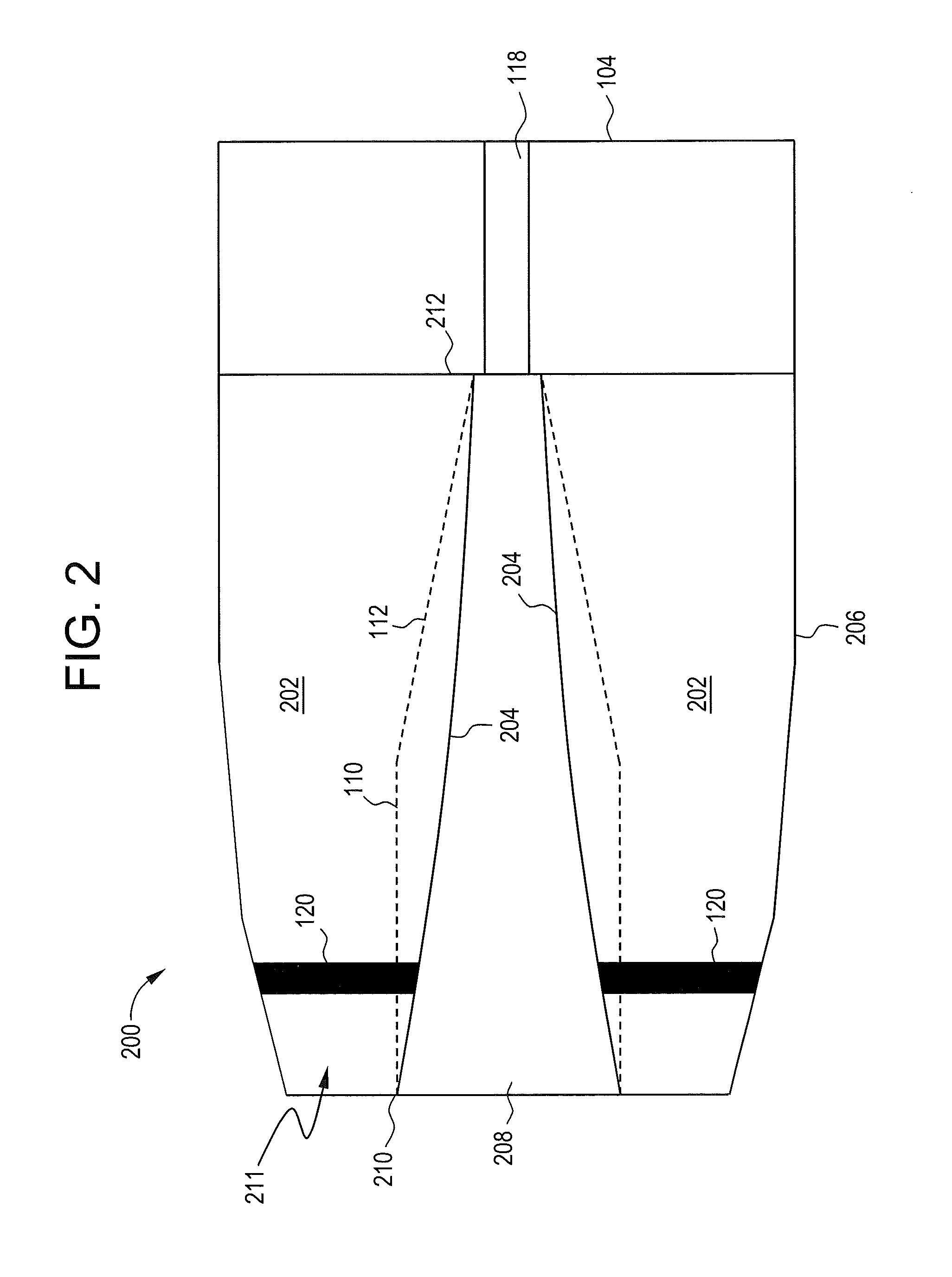

[0020]In one embodiment of the present invention, flow-path area is controlled in the strut passage through shaping of the diffuser inner barrel (inner wall). This flow path shaping is achieved through having maximum opening at the minimum area section in diffuser that is at maximum strut thickness with controlled variation upstream and downstream of strut generates inner wall flow path shape and is often constrained by flow separation from walls. The center body end is the function of center body radius and the diffuser inner wall angle, Similarly casing is shaped retaining the end radius of outer wall and is function of radial swirl. In particular, and contrary to the prior art in which the inner wall includes one or more “flat” sections, the inner wall may, in one embodiment, may be formed such that the inner wall is a curved from the inlet to an end of a center body section of the diffuser. The result is reduced strut blockage and, therefore, a reduction of loss through the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com