Fabric for Airbag

a technology of fabric and airbag, which is applied in the direction of weaving, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of high manufacturing cost, increased material and increased mass of woven fabric coated with synthetic rubber. , to achieve the effect of low cost and excellent accommodation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

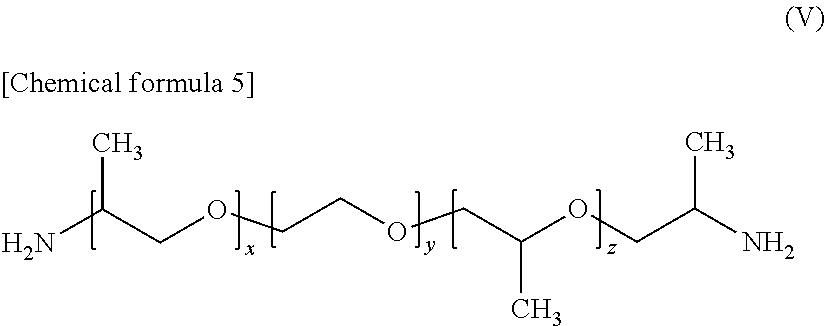

[0075]A polyamide 66 fiber of a total fineness of 470 dtex, 72 filaments, and a boiling water shrinkage degree of 5.5% was woven in a water jet room in a plain weaving manner, shrinkage-processed with boiling water, and drying-finished at 110° C. to obtain a woven fabric having a warp density of 46 / 2.54 cm and a weft density of 46 / 2.54 cm. Using a polymer obtained by polymerizing a polyamide 6, a polyethylene glycol-propylamine adduct (number average molecular weight 600) and adipic acid at a molar ratio of 2.5:1:1, an aqueous resin dispersion having a solid matter concentration of 15% by mass was made. Then, to the aqueous dispersion was added carboxymethylcellulose (07326-95, manufactured by Nacalai Tesque) at 3% by mass relative to the aqueous resin, and a viscosity was adjusted to 230 dPa·s. An aqueous dispersion of this resin composition was coated on the woven fabric by knife coating, at a resin amount after drying of 3 g / cm2. Properties of this woven fabric were assessed, and...

example 2

[0076]A polyamide 66 fiber of a total fineness of 350 dtex, 108 filaments, and a boiling water shrinkage degree of 8.5% was woven in a water jet room in a plain weaving manner, shrinkage-processed with boiling water, and drying-finished at 110° C. to obtain a woven fabric having a warp density of 53 / 2.54 cm and a weft density of 53 / 2.54 cm. Using a polymer obtained by polymerizing a polyamide 6, a polyethylene glycol-propylamine adduct (number average molecular weight 1000) and adipic acid at a molar ratio of 2.0:1:1, an aqueous resin dispersion having a solid matter concentration of 10% by mass was made. Then, to the aqueous dispersion was added carboxymethylcellulose (07326-95, manufactured by Nacalai Tesque) at 2% by mass relative to the aqueous resin, and a viscosity was adjusted to 120 dPa·s. An aqueous dispersion of this resin composition was coated on the woven fabric by knife coating, at a resin amount after drying of 4 g / cm2. Properties of this woven fabric were assessed, a...

example 3

[0077]A polyamide 66 fiber of a total fineness of 470 dtex, 72 filaments, and a boiling water shrinkage degree of 5.5% was woven in a water jet room in a plain weaving manner, shrinkage-processed with boiling water, and drying-finished at 110° C. to obtain a woven fabric having a warp density of 43 / 2.54 cm and a weft density of 43 / 2.54 cm. Using a polymer obtained by polymerizing a polyamide 6, adipic acid, and polyethylene glycol (number average molecular weight 600) at a molar ratio of 1.8:1:1, an aqueous resin dispersion having a solid matter concentration of 6% by mass was made. Then, to the aqueous dispersion was added carboxymethylcellulose (07326-95, manufactured by Nacalai Tesque) at 2% by mass relative to the aqueous resin, and a viscosity was adjusted to 105 dPa·s. An aqueous dispersion of this resin composition was coated on the woven fabric by knife coating, at a resin amount after drying of 8 g / cm2. Properties of this woven fabric were assessed, and results are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| air permeability | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com