Integrated Air/Oil Reservoir Cooler and Noise Reduction System

a technology of air/oil reservoir cooler and noise reduction system, which is applied in the direction of machines/engines, liquid fuel engines, light and heating apparatus, etc., can solve the problems of insufficient cooling system performance and excessive heat of pumps, and achieve the effect of reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

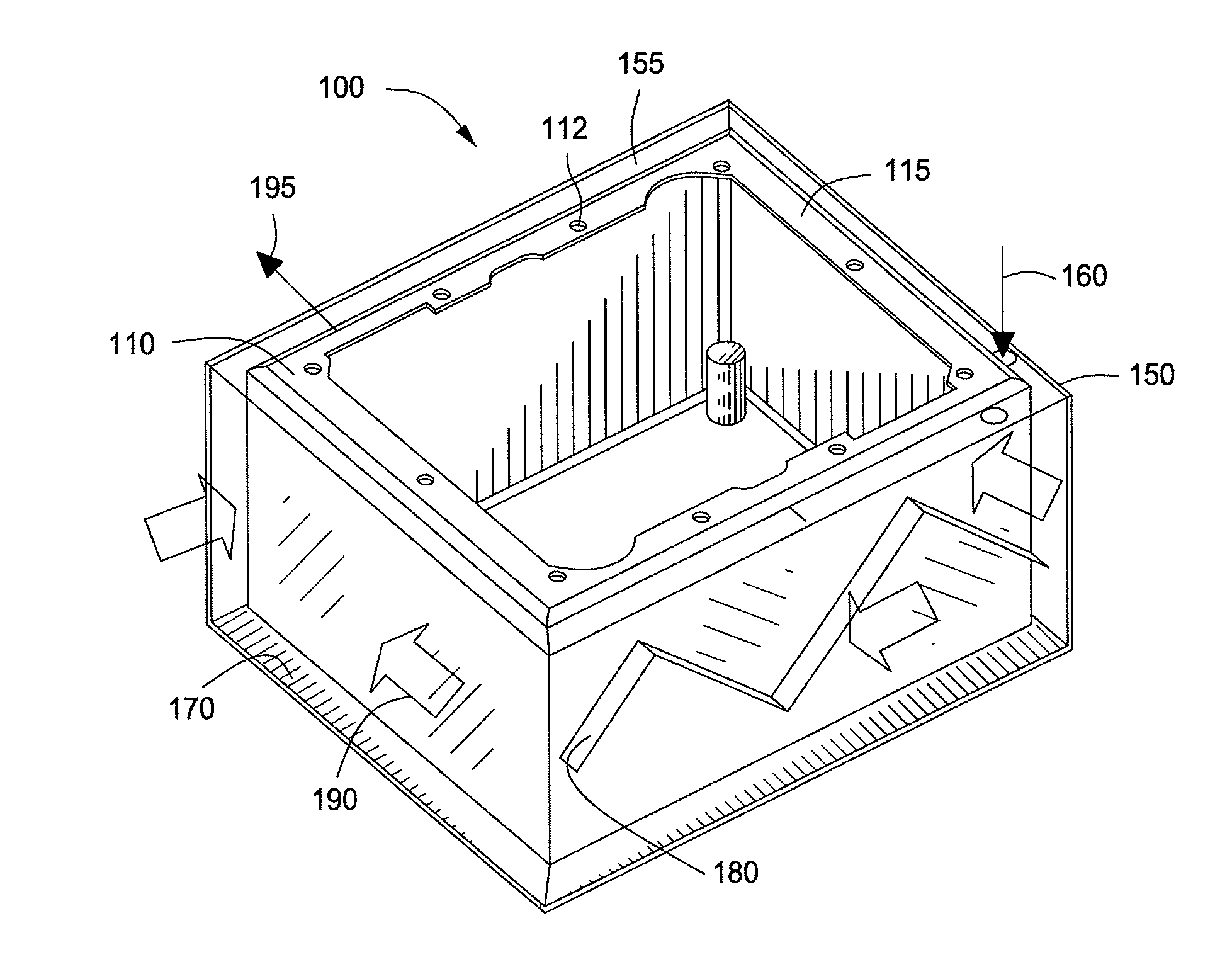

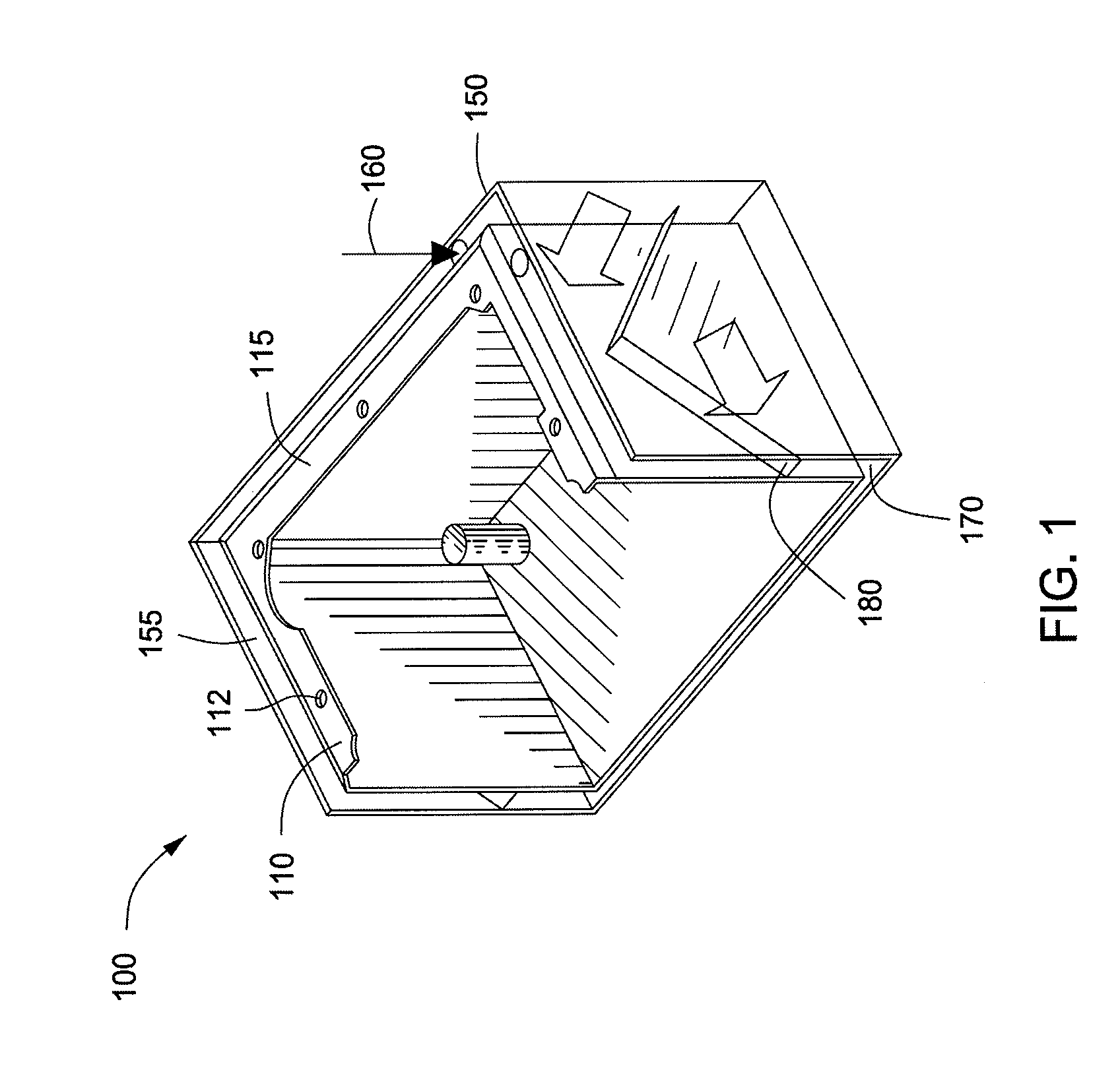

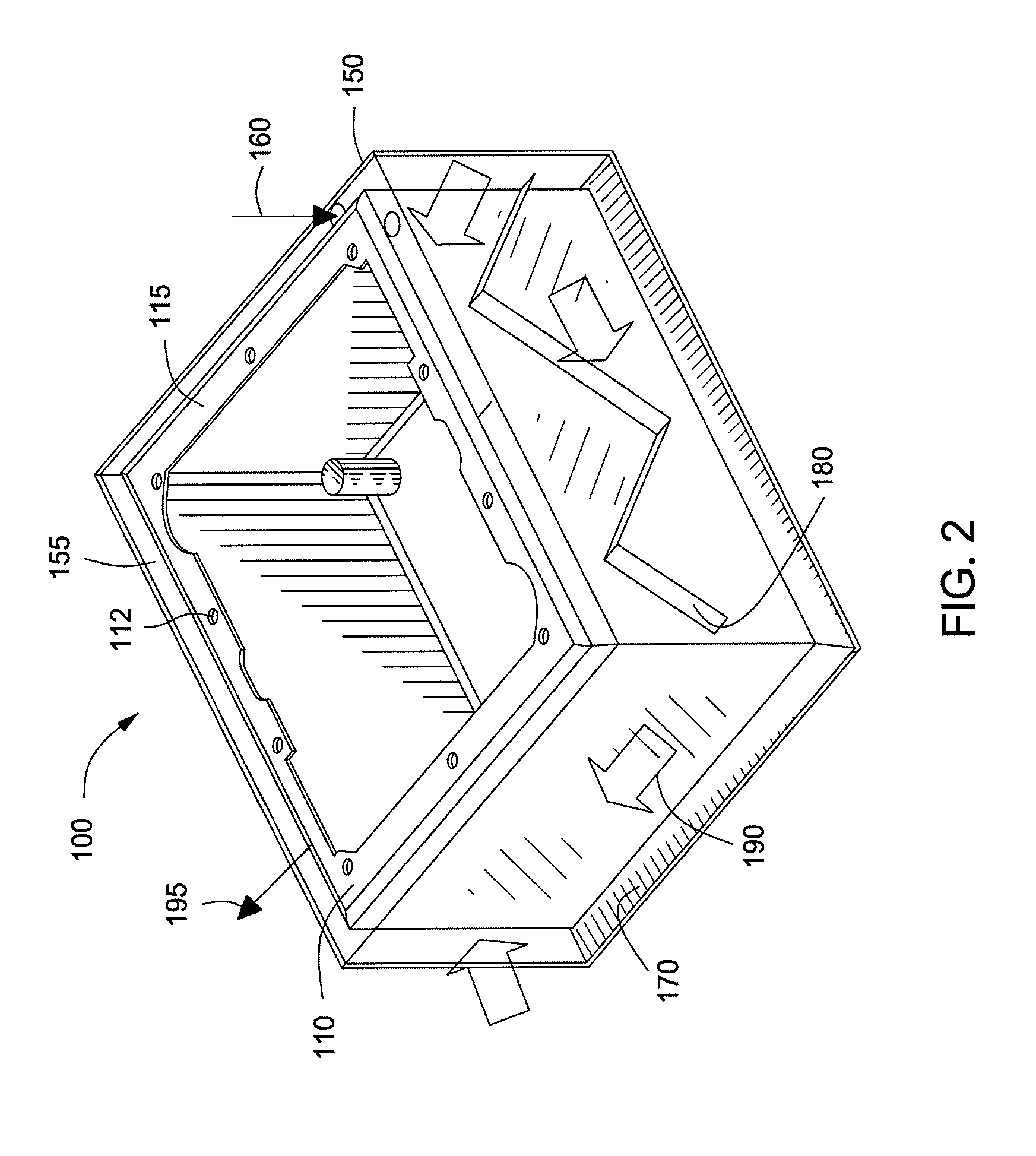

[0014]The invention will now be described with reference to the drawing figures, in which like reference numerals refer to like parts throughout. An embodiment in accordance with the invention provides a pump, such as an air / hydraulic pump that includes a cooling system that cools a working fluid such as hydraulic fluids used in the pump and reduces noise during the cooling system's operation.

[0015]The working fluid can be any fluid including, for example, hydraulic fluids, oils, lubricants, water, phosphate ester, water-based ethylene glycol compounds, and silicone fluids. Three most common types of hydraulic liquids are petroleum-based, synthetic fire-resistant, and water-based fire-resistant. The working fluid can be synthetic, naturally occurring or a combination thereof. As noted, any working fluid can be used with the invention and hydraulic fluid is just one exemplary fluid that can be used with invention. The cooling system combines a noise and vibration abatement system whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com