Solar Trough Field System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

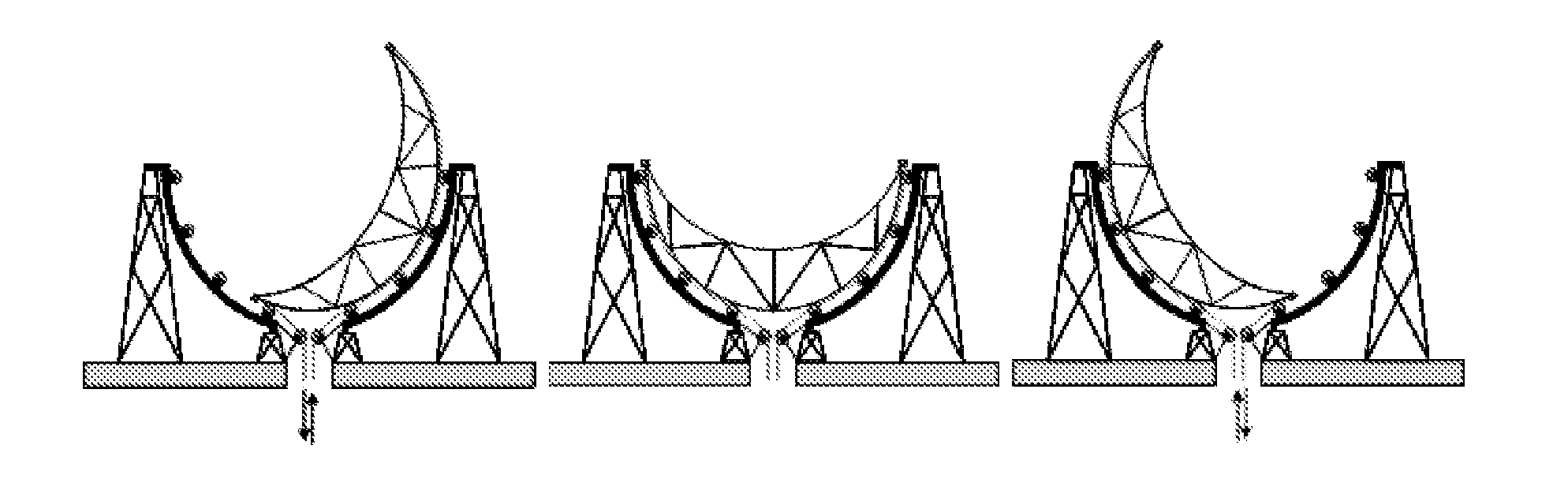

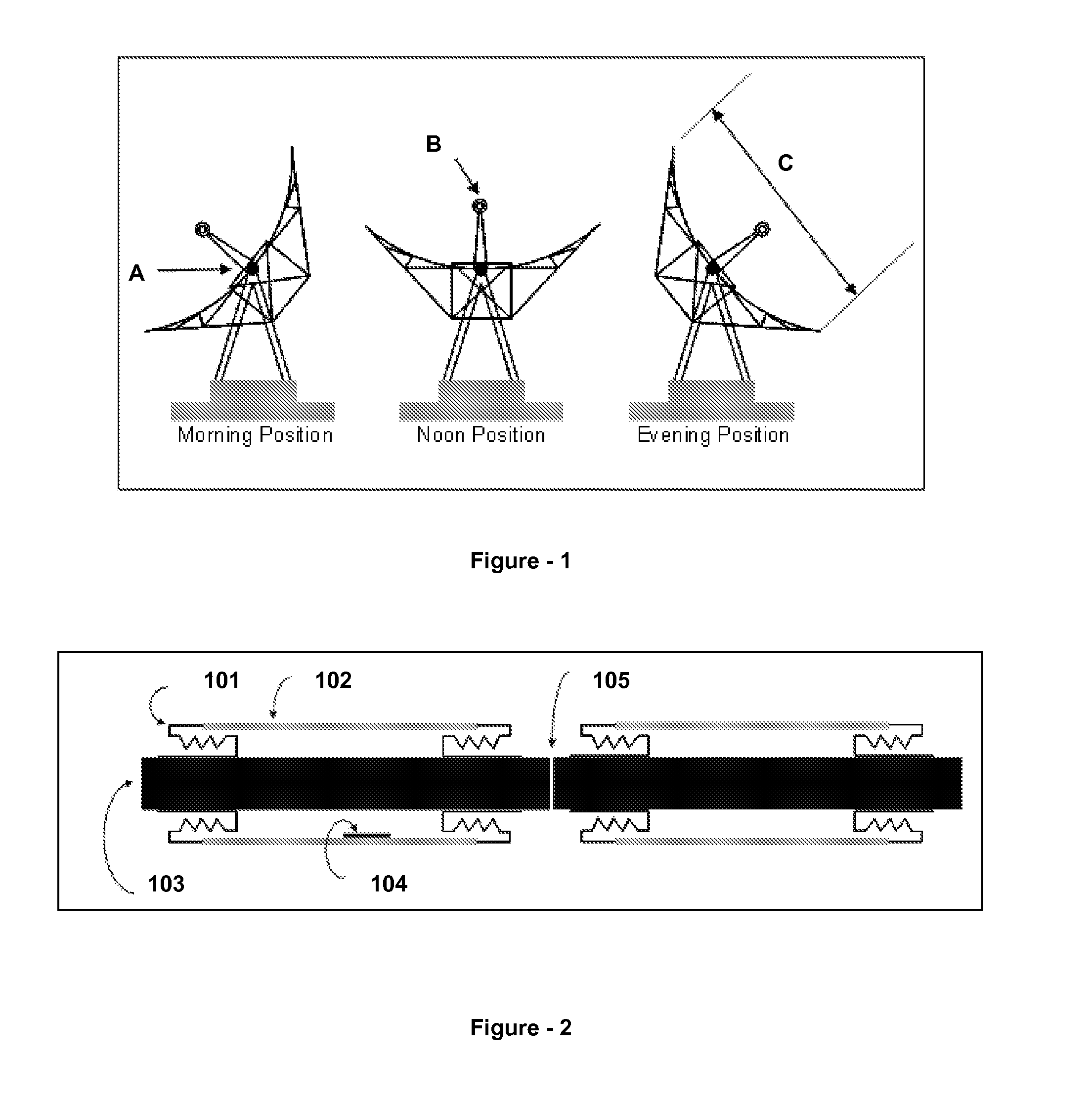

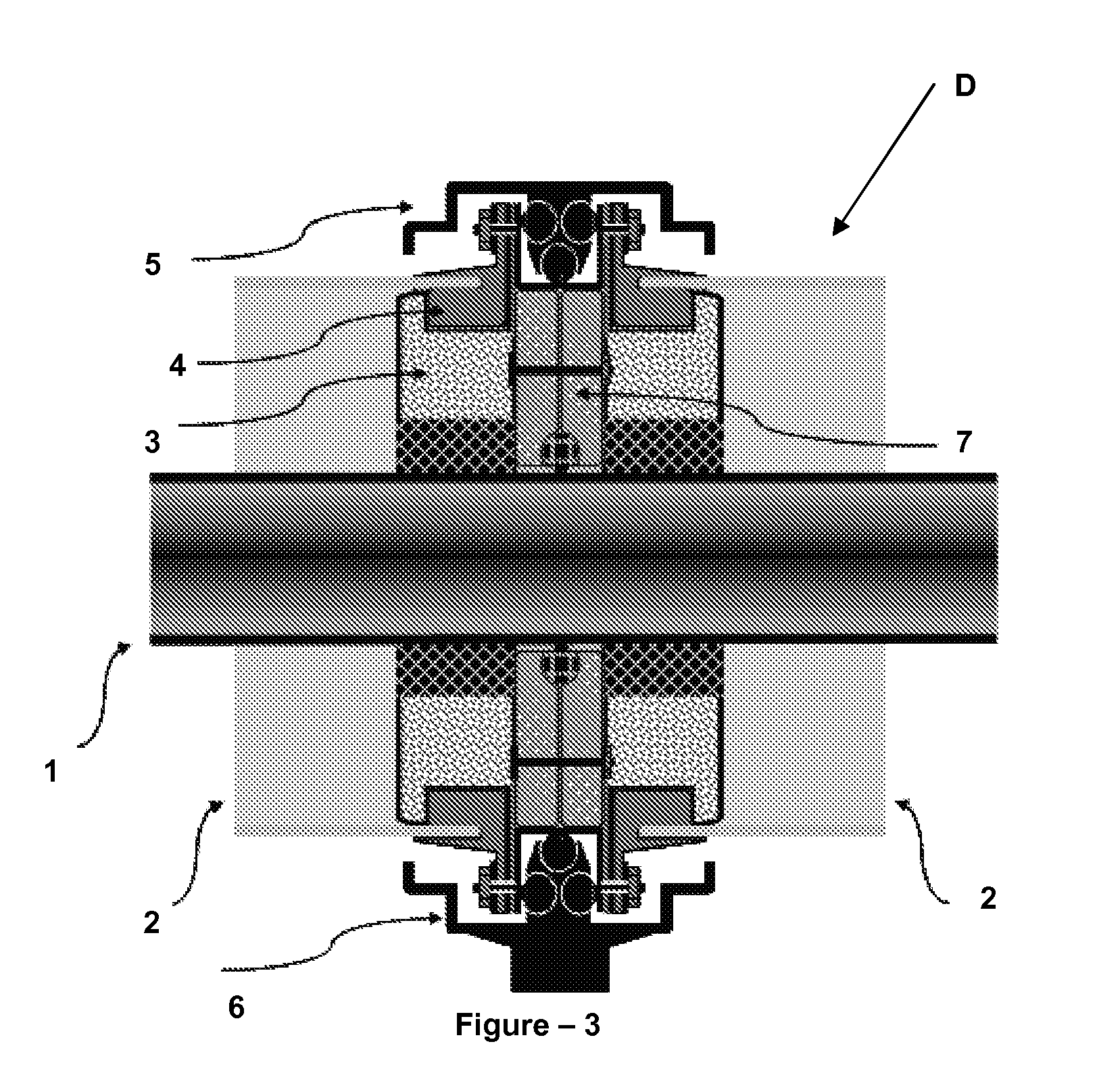

[0129]A solar trough field system according to the invention comprises multiple parabolic reflectors; a thermal receiver tube, center of which coincides with the focus of the parabolic reflectors and which consists of a metal heat receiving pipe (1) and a glass tube (2) which are nested (the glass tube surrounds the metal heat receiving pipe from outside); a “vacuum seal and glass tube connector system” (E) which connects the glass tubes (2) and the thermal heat receiving pipe (1) to each other; a rotating support unit (21), which connects the parabolic panel to the glass tube connector system (E) and provides the thermal receiver tube (1) to stay stationary while the parabolic panel is rotating around it; “flexible expansion unit” (29) located at the end of each parabolic trough unit which provides vacuum seal while the Heat Receiving Pipe (1) is moving due to heat expansion; and a vertical loop (52) located at the discharge side of the parabolic unit, which can be used instead of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com