Protective patch providing protection against the transfer of bodily secretions

a technology of bodily secretions and protective patches, which is applied in the field of protective patches, can solve the problems of major risk of various layers becoming delaminated and the fabrication process being more complex, and achieve the effects of preventing them from being dislodged, enhancing the strength of layers constituting the protective patch, and improving user comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

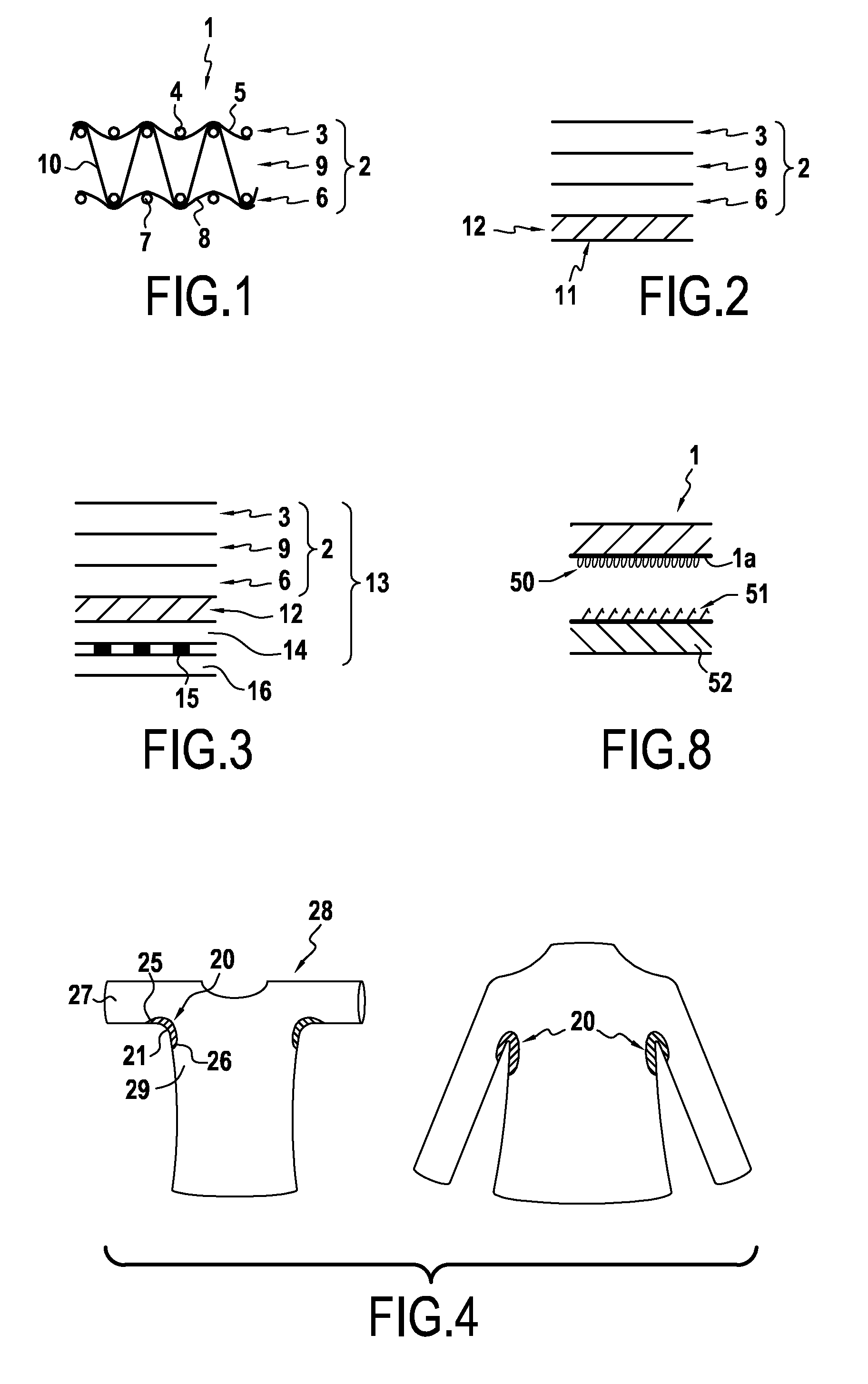

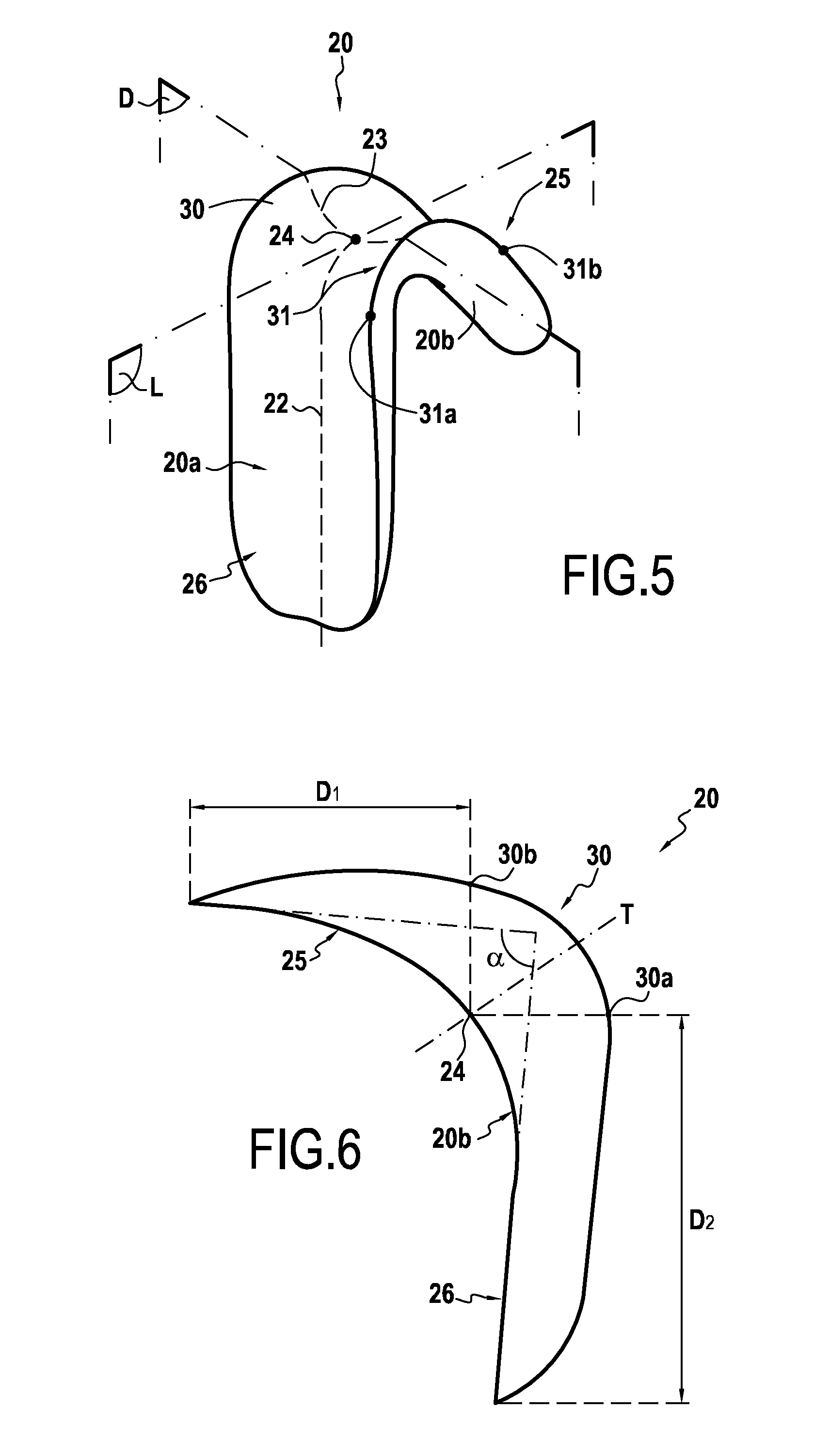

[0052]In the first embodiment, given in non-exclusive manner, the protective patch 1 consists of a fabric 2 that is said to be of the three-dimensional or 3D type in that it comprises two walls 3 and 6 that are both made of interlaced yarns, e.g., first warp yarns 4 and first weft yarns 5 for the first wall 3 and second warp yarns 7 and second weft yarns 8 for the second wall 6, said two walls 3 and 6 being connected together by a set 9 of link yarns, e.g., yarns 10 that, in the particularly simplified example shown in FIG. 1, pass in alternation over some of the first warp yarns 4 of the first wall 3 and under some of the second warp yarns 7 of the second wall 6. The technique for fabricating such a fabric of three-dimensional or 3D type is well known in the textile industry. It is possible to adjust the operating conditions of the loom used so as to determine accurately the distance between the two walls 3 and 6, which distance is occupied solely by the link yarns 10, and also so ...

second embodiment

[0064]Consequently, in the second embodiment shown in FIG. 2, the ptotective patch 11 also includes a breathable waterproof membrane 12 that is secured to the outside wall 6. Such a membrane 12 enhances the looked-for moisture barrier effect, while presenting sufficient porosity to allow air to circulate, which is useful for avoiding localized heating of the space between the patch and the wearer's body, which heating is likely in particular to accentuate perspiration. This porosity must also be sufficient to allow the moisture contained in the fabric 2 to be discharged in the form of water vapor, thereby correspondingly restoring its capacity to absorb moisture.

[0065]The technique for securing the breathable waterproof membrane 12 to the outside wall 6 must enable the membrane to retain its porosity. It is preferable to use dots of hot-melt type adhesive.

third embodiment

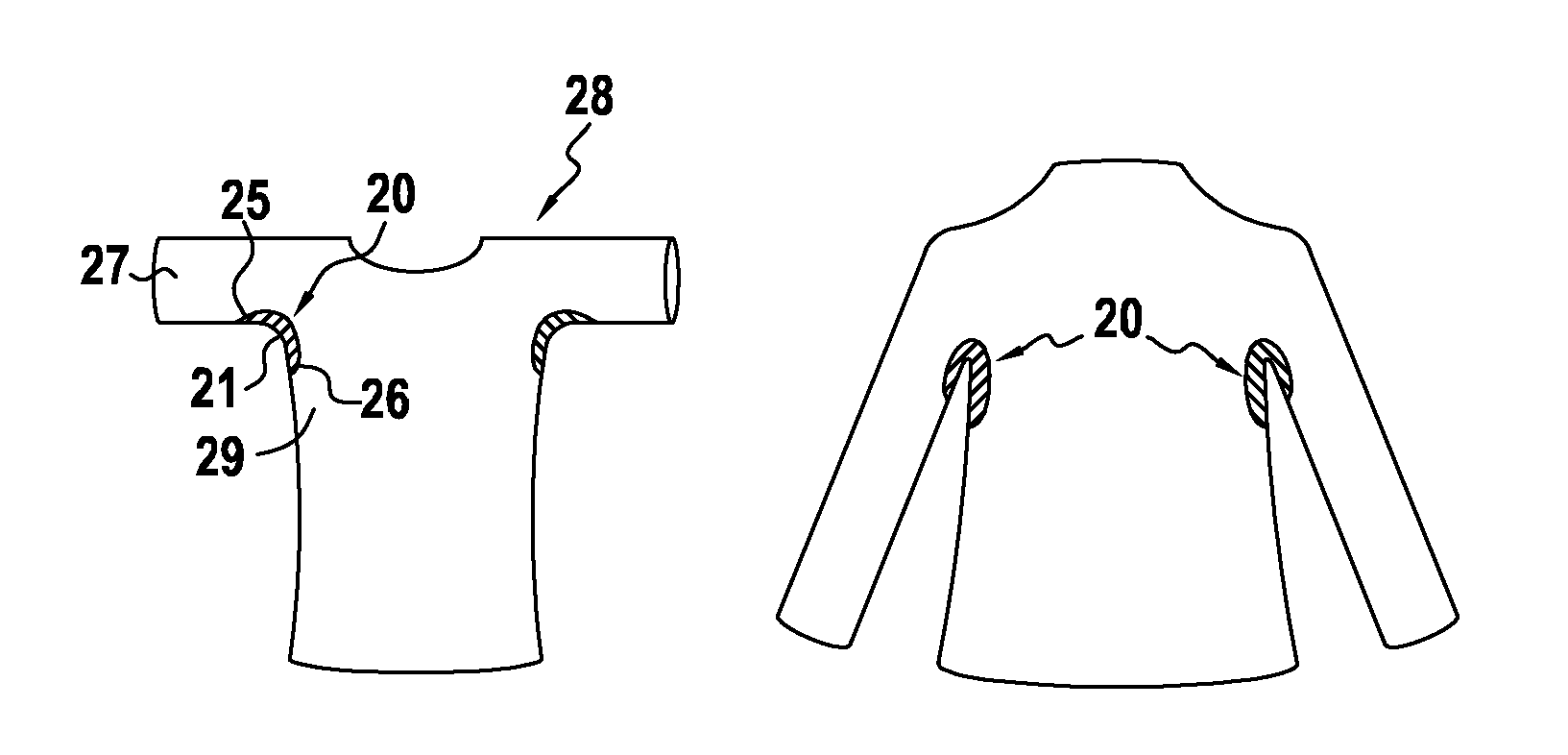

[0066]FIG. 3 shows a protective patch 13 that differs from the second by securing an outer layer 14 on the breathable waterproof membrane 12, e.g., a layer of non-woven or lightweight textile having an adhesive 15 on its outside face, which adhesive is protected by an anti-adhesive sheet 16.

[0067]In this third embodiment, the protective patch 13 may be put into place directly by the user. It suffices to remove the anti-adhesive sheet 16 and to press the adhesive 15 against the inside face of the armpit zone 21 of an article of clothing 28.

[0068]The use of the outer layer 14 in this third embodiment is justified by the risk of delamination that might occur between the breathable waterproof membrane 12 and the article of clothing 28 were the adhesive 15 to be applied directly to said membrane 12.

[0069]More generally, the presence of an outer layer 14 is justified whenever there is a risk of the membrane being degraded or delaminated, either during manufacture of the protective patch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com