Energy storage unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

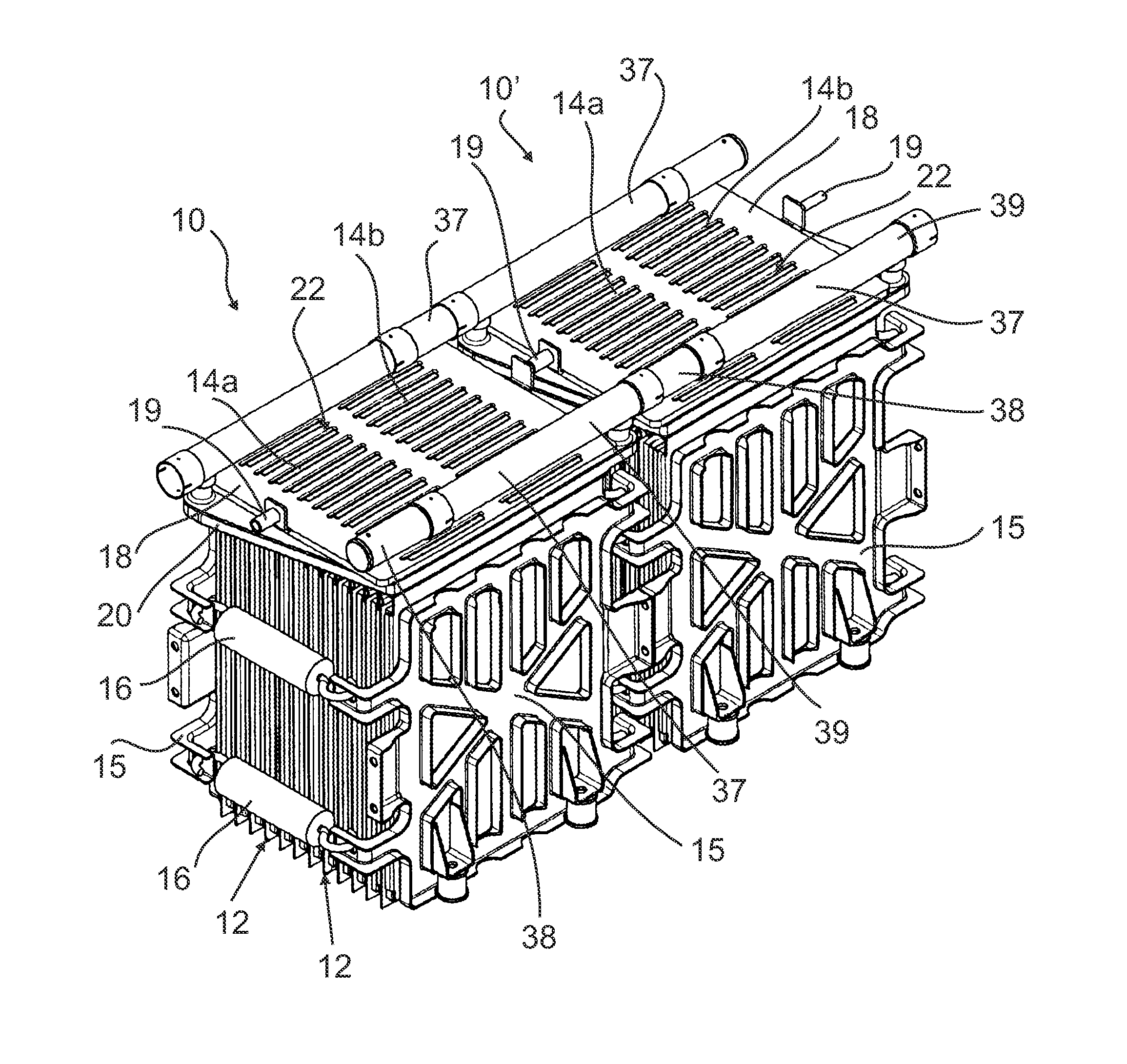

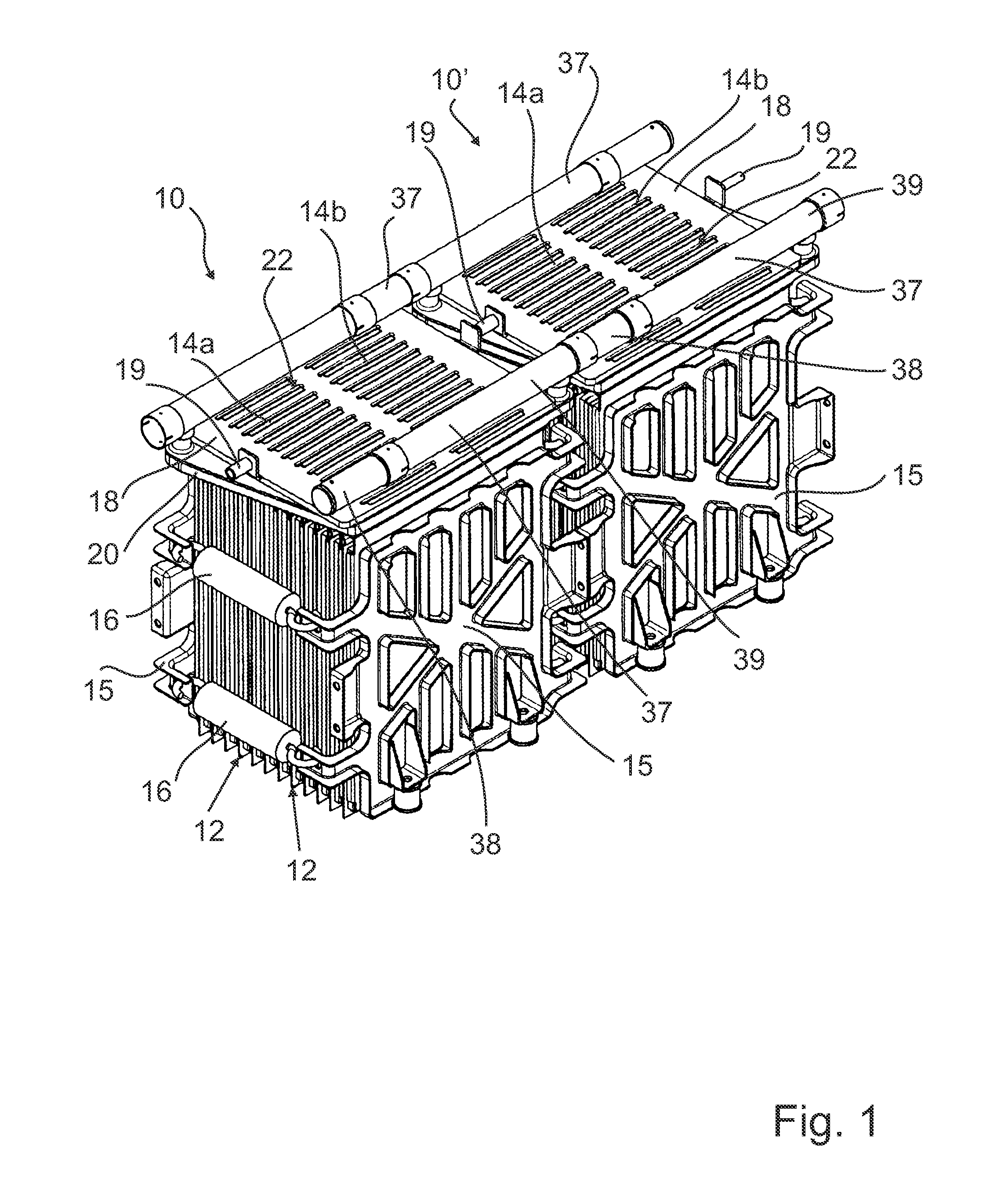

[0030]FIG. 1 shows a perspective view of two energy storage units 10, 10′. The two energy storage units 10, 10′ are joined together in order to form a superordinate unit. Within the framework of a modular concept, thus, depending on the application requirement, any number of energy storage units can be joined together in a line or be combined to form a two- or three-dimensional matrix in order to eventually constitute a vehicle battery, for example.

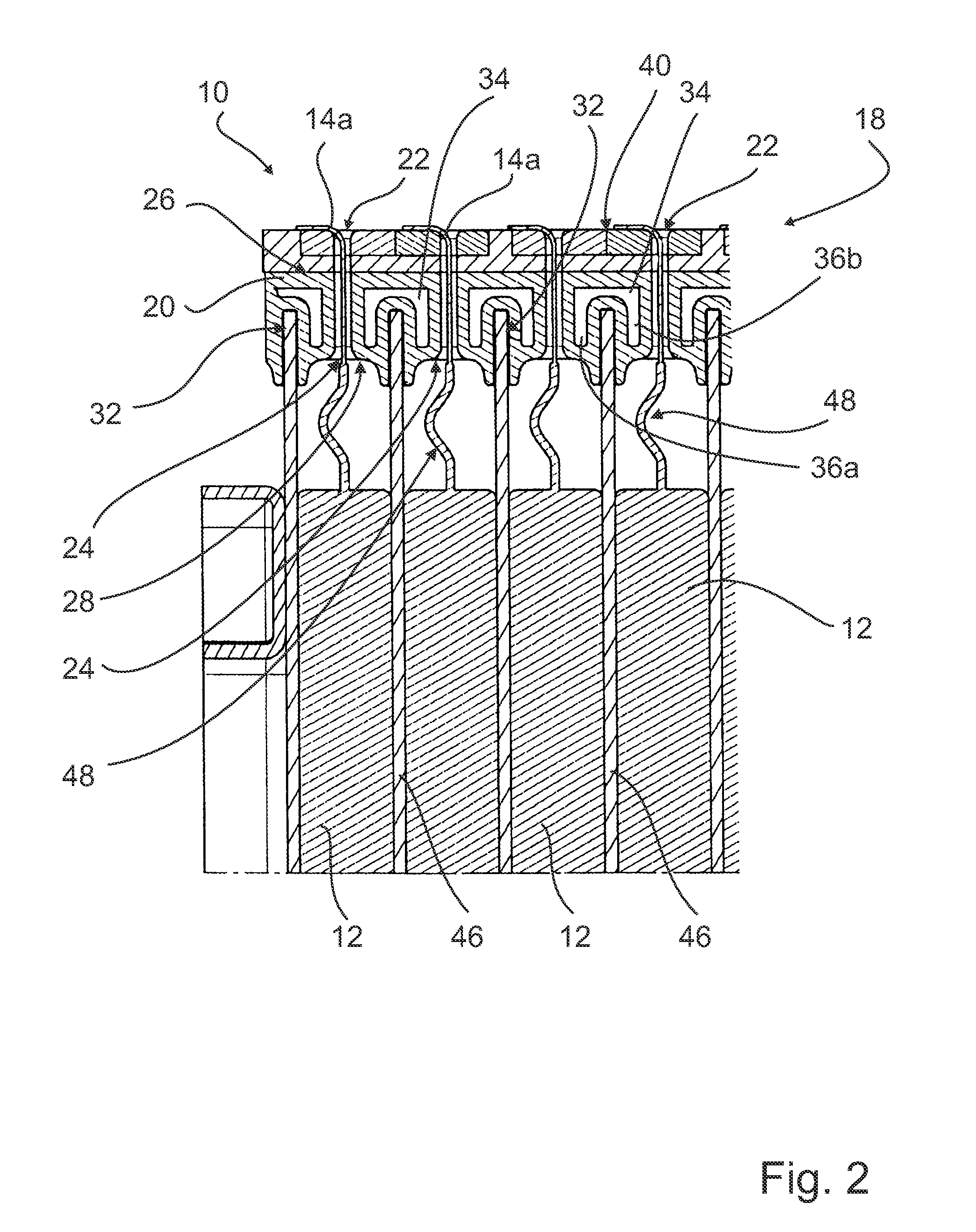

[0031]Each of the energy storage units 10, 10′ comprises a plurality of prismatic cells / flat cells 12 arranged in parallel to one another in a stack. The cells 12 can, for example, be lithium ion accumulator cells or double-layer capacitor cells (“supercaps”). Each of the individual cells 12 has two electrode tabs 14a, 14b protruding from the narrow side thereof. A plate-shaped interconnection board 18 serves for an electrical through-connection of the cells 12. In the case of the exemplary embodiment described, the cells 12 are serially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com