Rotary engine lip-seal apparatus and method of operation therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

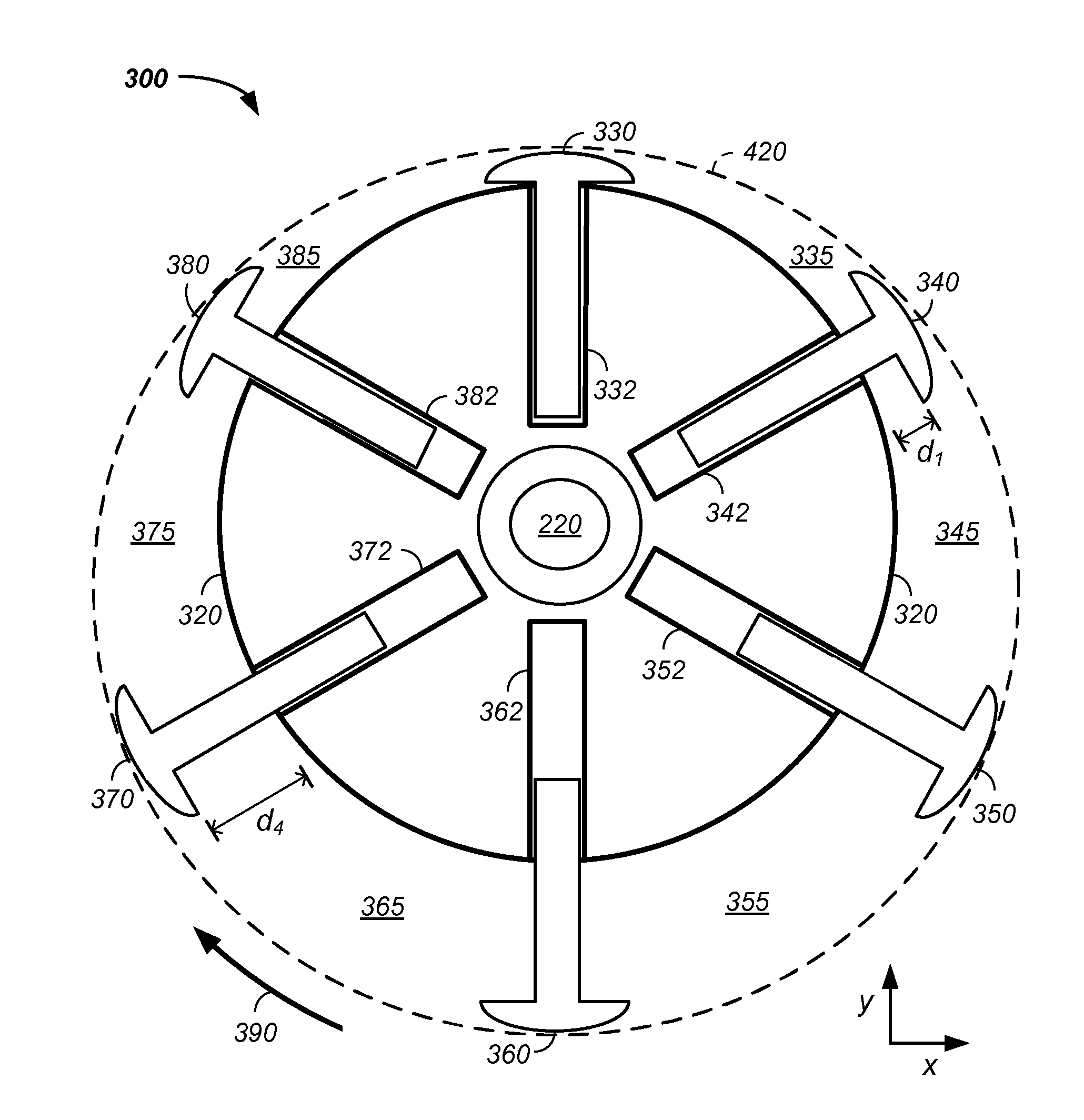

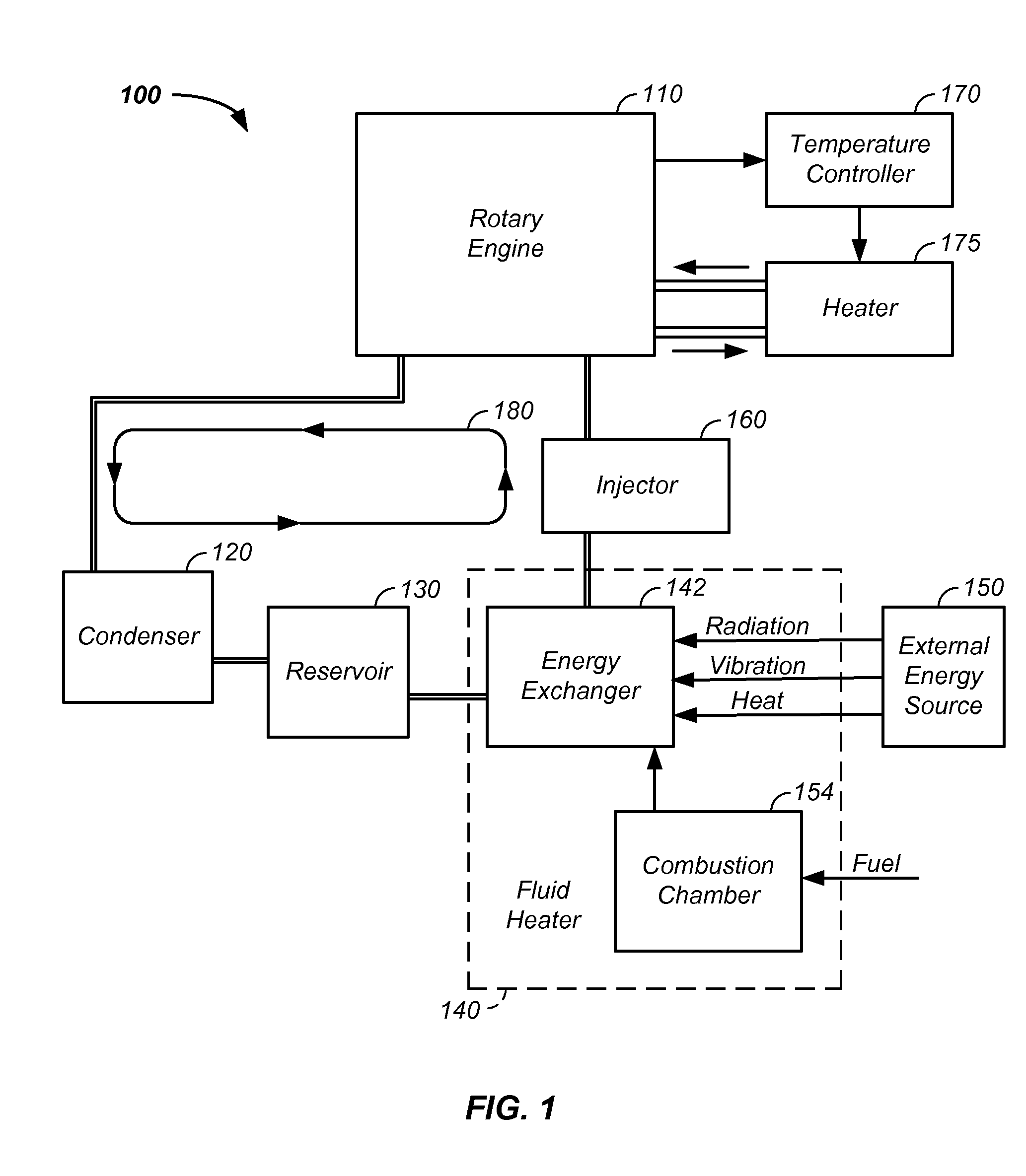

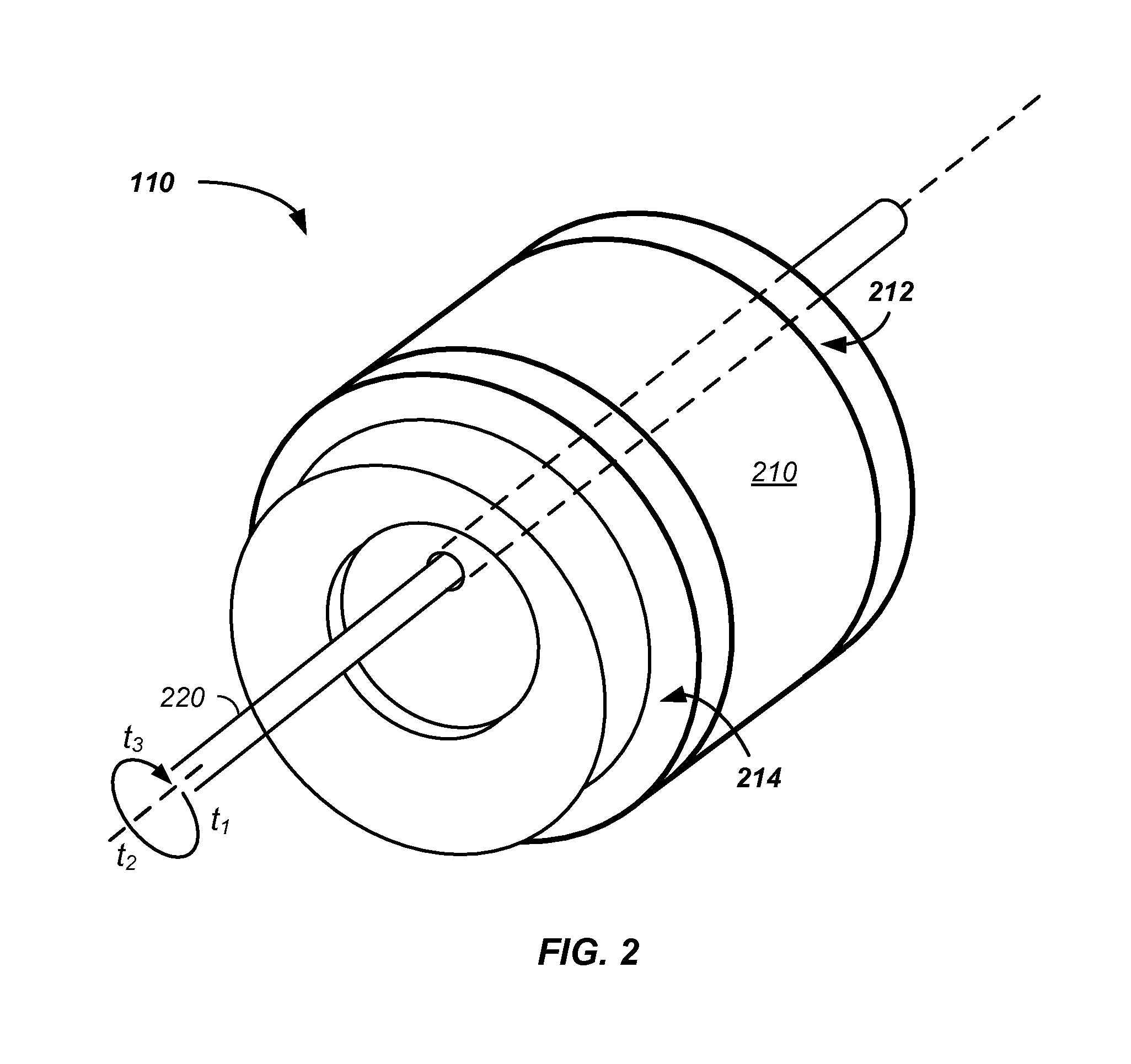

[0151]The invention comprises a rotary engine method and apparatus configured with at least one lip seal. A lip seal restricts fuel flow from a fuel compartment to a non-fuel compartment and / or fuel flow between fuel compartments, such as between a reference expansion chamber and any of an engine: rotor, vane, housing, and / or a leading or trailing expansion chamber. Types of lip seals include: vane lip seals, rotor lip seals, and rotor-vane slot lip seal. Generally, lip seals dynamically move or deform as a result of fuel movement or pressure to seal a junction between a sealing surface of the lip seal and a rotary engine component. For example, a vane lip seal sealing to the inner housing dynamically moves along the y-axis until an outer surface of the lip seal seals to the housing.

[0152]In another embodiment, the rotary engine method and apparatus uses an offset rotor. The rotary engine is preferably a component of an engine system using a recirculating liquid / vapor.

[0153]In yet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com