Wireless telemetry systems for downhole tools

a technology of telemetry system and downhole tool, which is applied in the field of telemetry system, can solve the problems of difficult to provide such communication using a cable, the cable inside the tubing is also an additional complexity, and the operator does not obtain direct feedback from the downhole tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

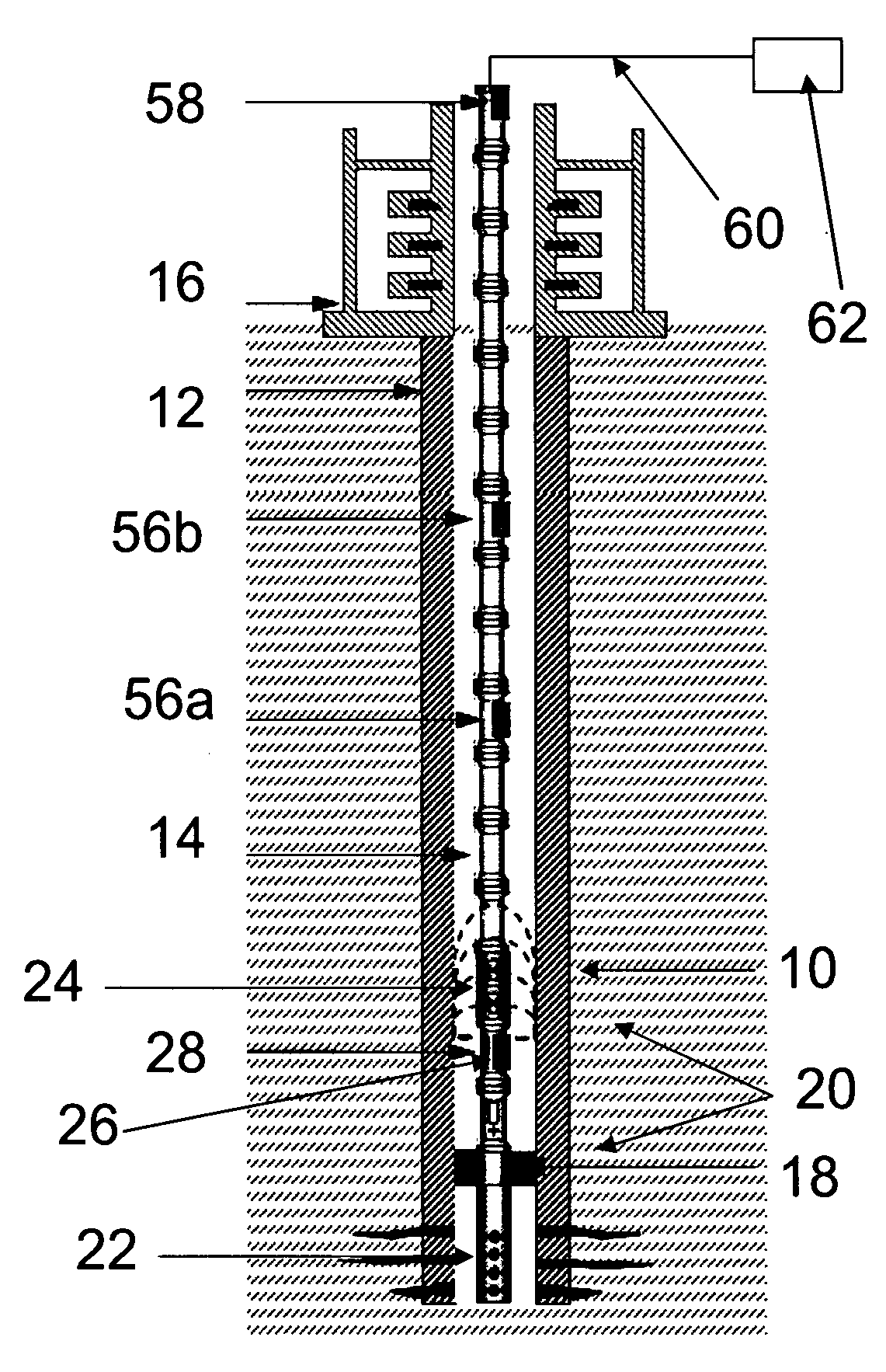

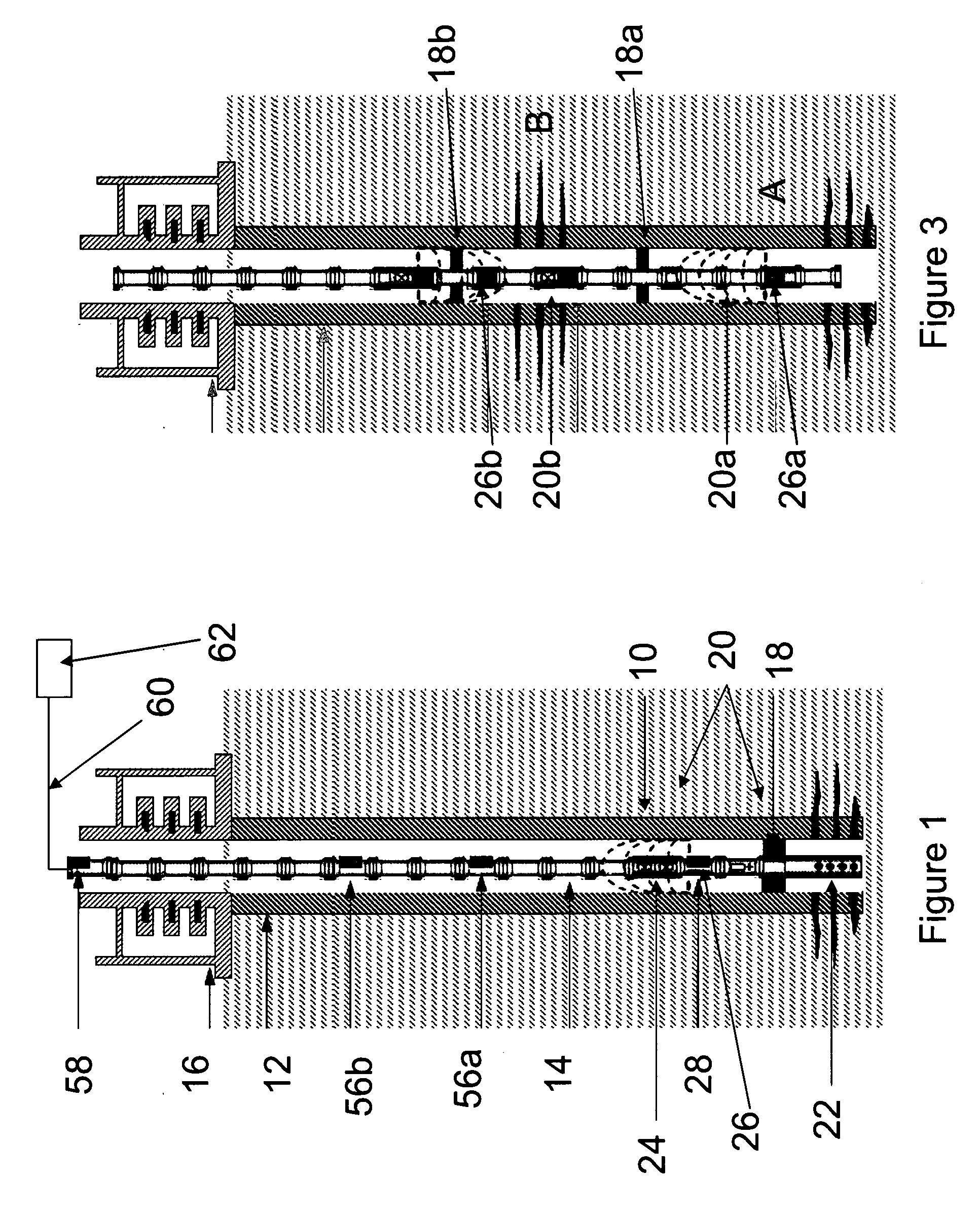

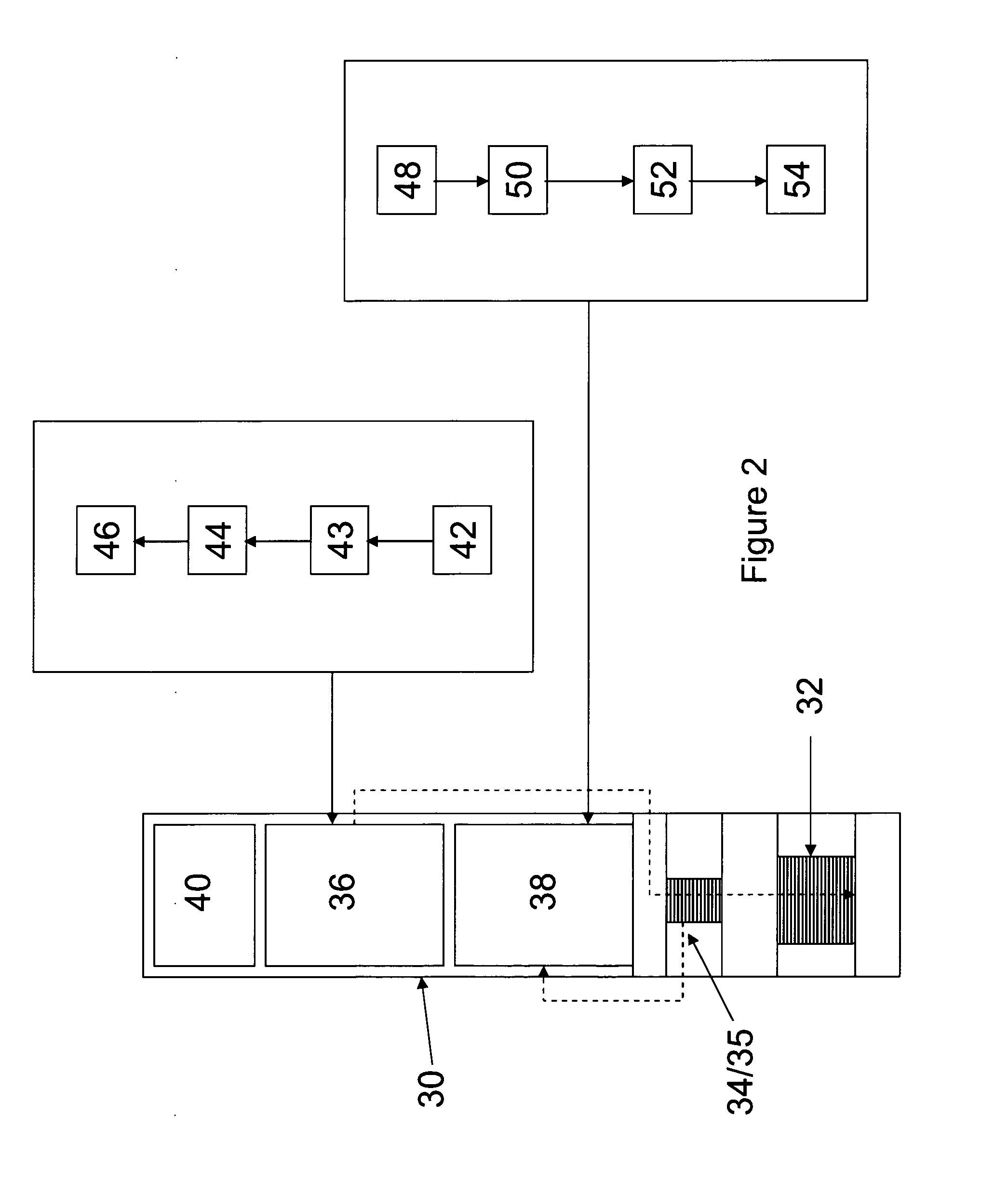

[0038]The present invention is particularly applicable to testing installations such as are used in oil and gas wells or the like. FIG. 1 shows a schematic view of such a system. Once the well has been drilled through a formation, the drill string can be used to perform tests, and determine various properties of the formation though which the well has been drilled. In the example of FIG. 1, the well 10 has been lined with a steel casing 12 (cased hole) in the conventional manner, although similar systems can be used in unlined (open hole) environments. In order to test the formations, it is preferable to place testing apparatus in the well close to the regions to be tested, to be able to isolate sections or intervals of the well, and to convey fluids from the regions of interest to the surface. This is commonly done using a jointed tubular drill pipe, drill string, production tubing, or the like (collectively, tubing 14) which extends from the well-head equipment 16 at the surface (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com