Bed-type circular saw blade grinder

a circular saw blade and grinder technology, applied in the field of grinding technique of saw blades, can solve the problems of unfavorable processing quality, unfavorable use, and inability to meet the needs of customers, and achieve the effects of convenient manufacture, reduced cost, and simplified structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

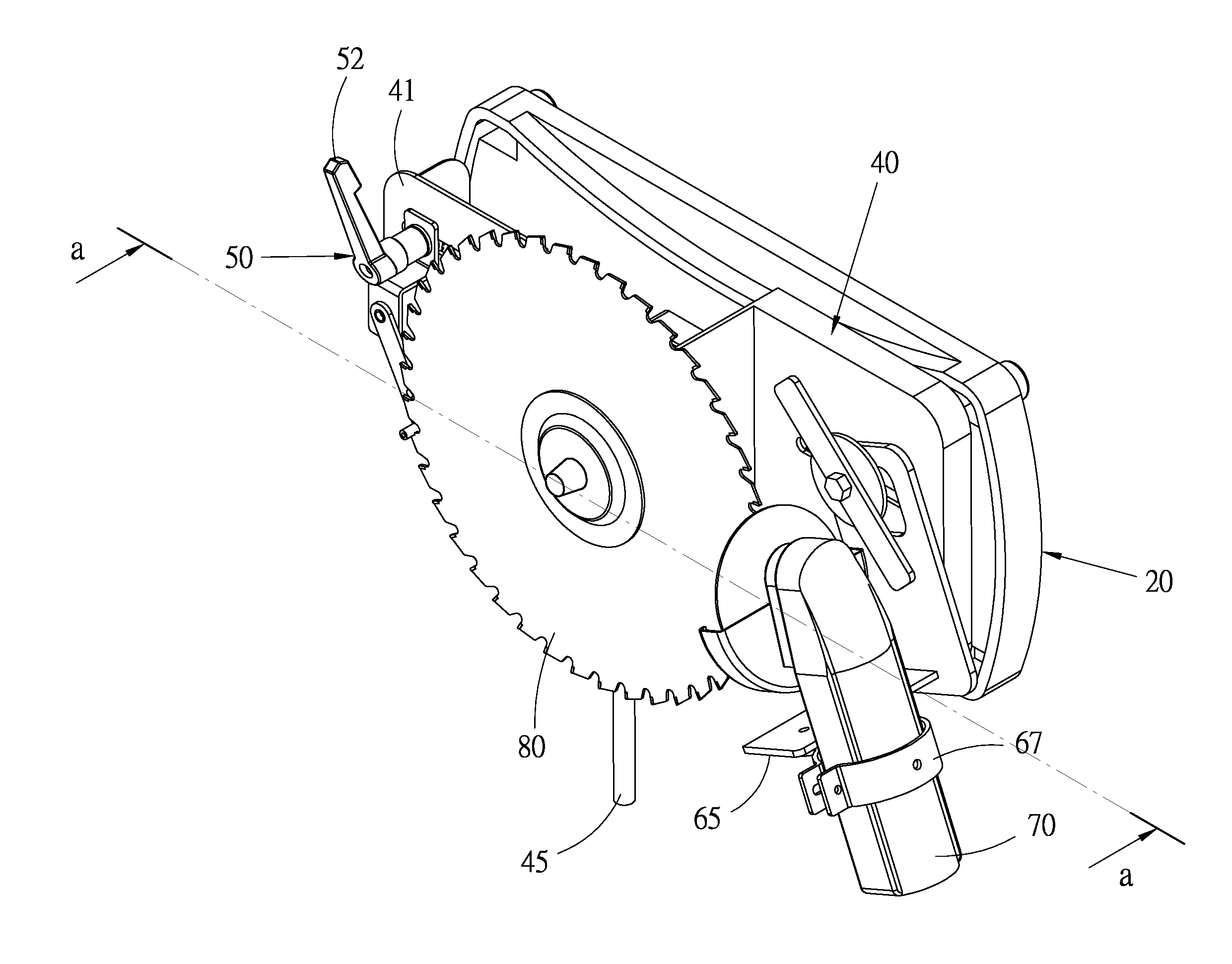

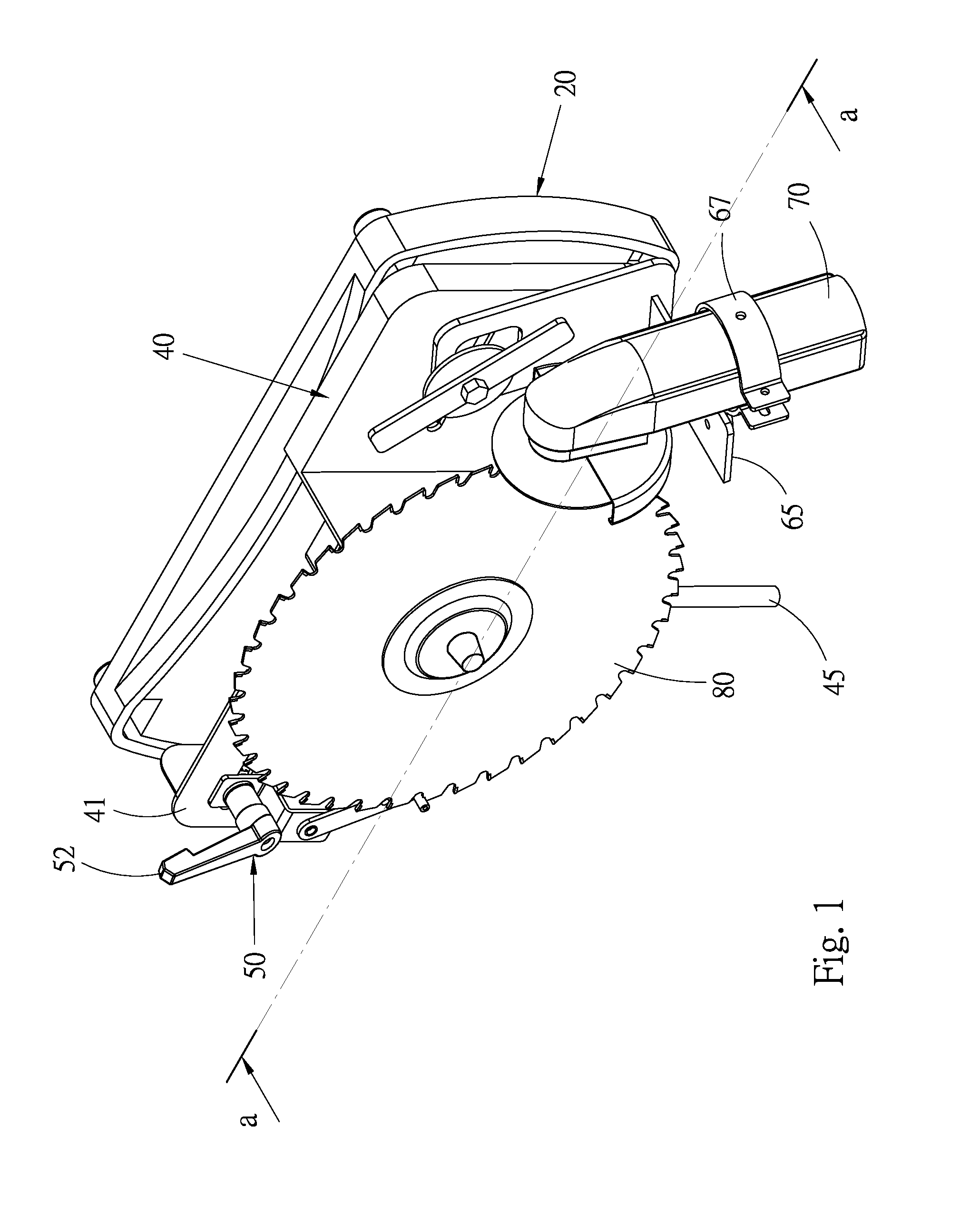

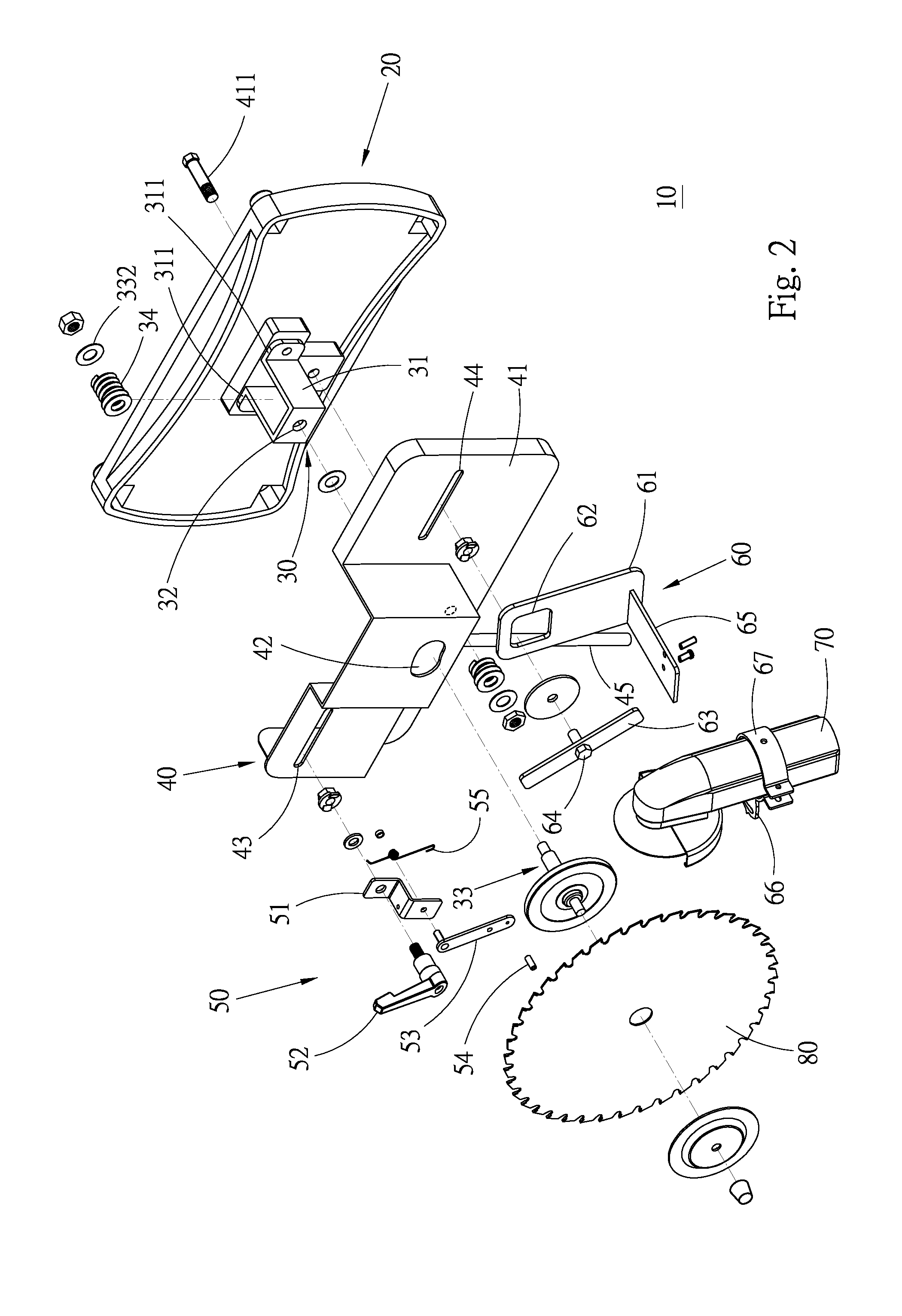

[0018]Please refer to FIGS. 1 to 9. According to a preferred embodiment, the bed-type circular saw blade grinder 10 of the present invention includes a bed section 20, a support section 30, a rotary seat 40, a circular saw blade restriction section 50, a grinding unit retainer seat 60 and a grinding unit 70.

[0019]The bed section 20 is a board body with a certain weight as a base on which the other components of the bed-type circular saw blade grinder 10 are mounted. The bed section 20 also helps in stabilizing the operation of the bed-type circular saw blade grinder 10.

[0020]The support section 30 has a substantially U-shaped support body 31 with a certain height. Two wing plates 311 laterally extend from bottom ends of two sides of the support body 31. The wing plates 311 are attached to and fixedly connected with an upper face of the bed section 20. A top wall of the support body is formed with a shaft hole 32. The shaft hole 32 has an axis normal to the upper face of the bed sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| frictional force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com