Thermoformed package with tamper evident seal

a technology of thermal insulation and sealing seals, applied in the field of packaging, can solve the problems of time-consuming and laborious process of feeding packages through sealing equipment after filling, and the end consumer is difficult to open the package, and achieves the effect of sufficient adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

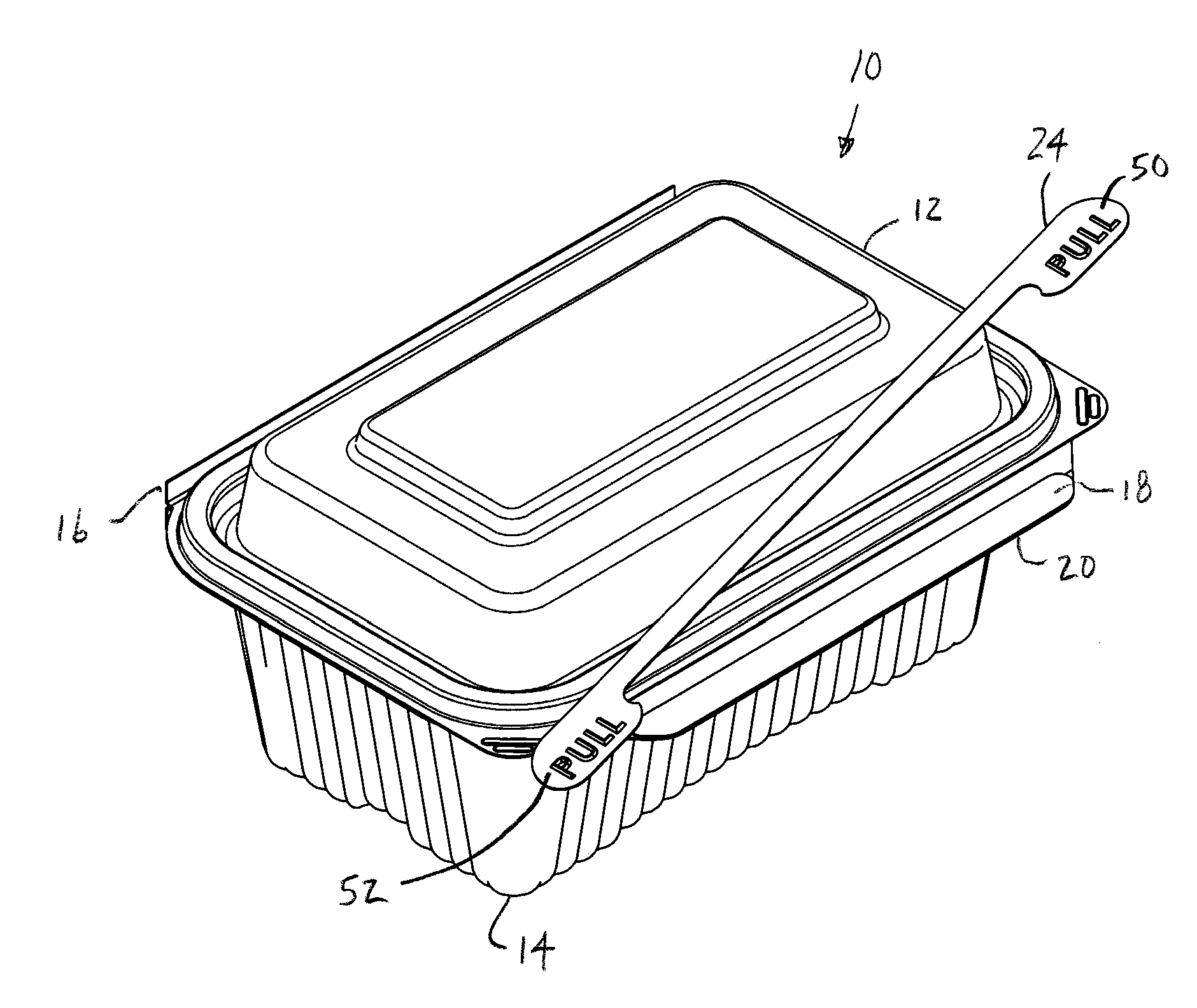

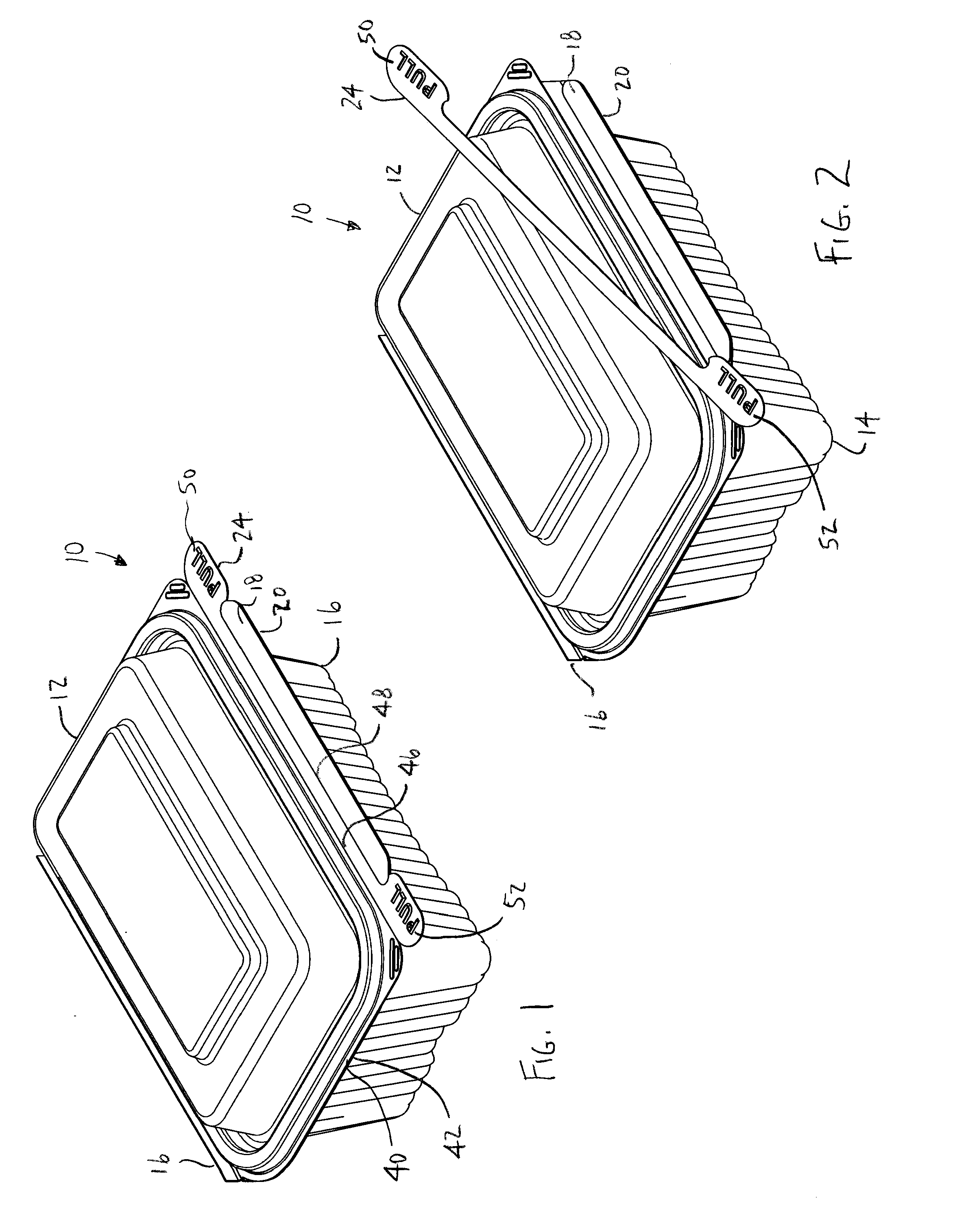

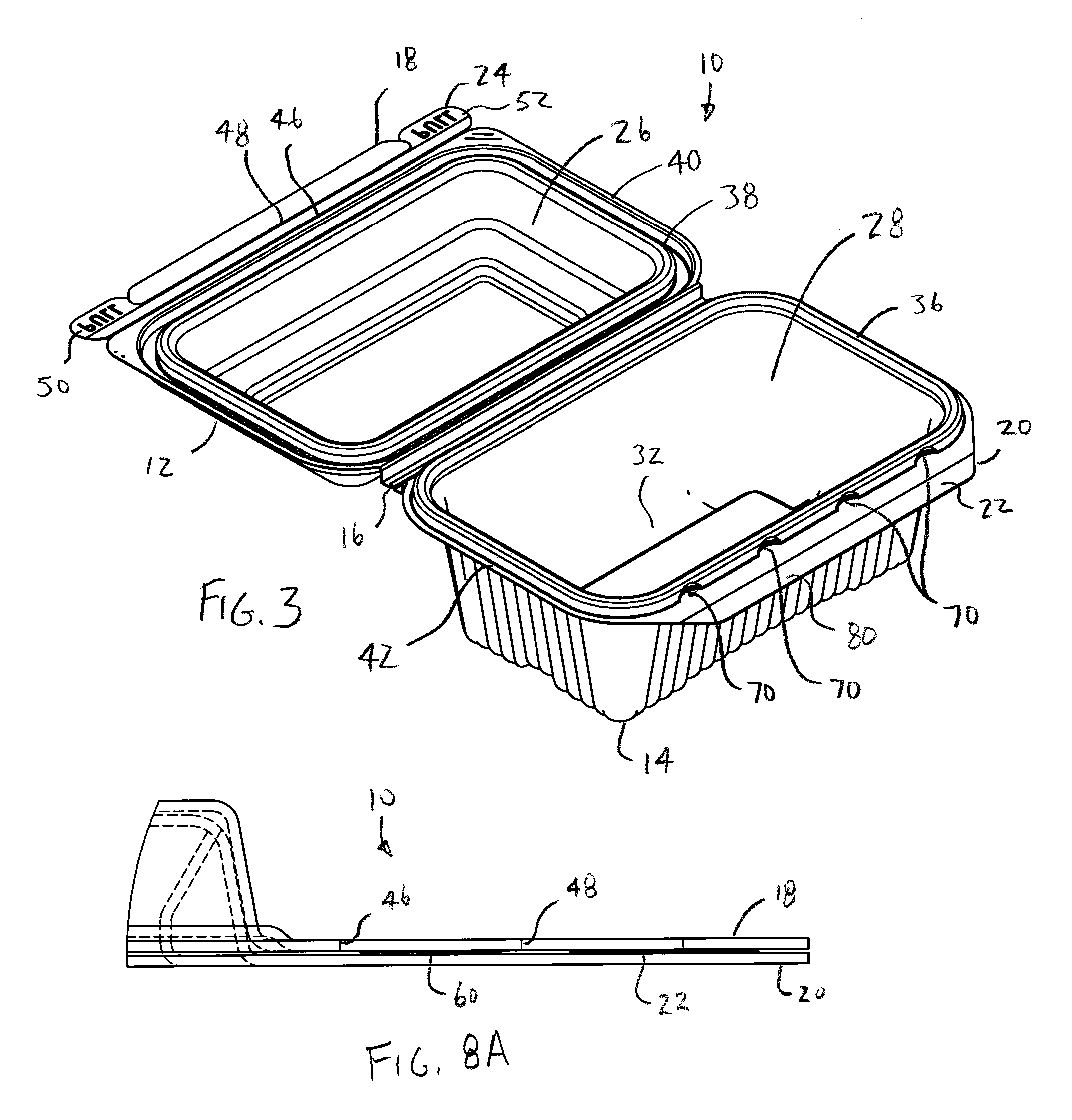

[0032]A thermoformed package in accordance with an embodiment of the present invention is shown in FIGS. 1 and 2. The package 10 of this embodiment is a clamshell package having a top part 12 and a bottom part 14 joined along a living hinge 16 that allows the package 10 to be easily opened and closed. The free edge of the top part 12 includes a sealing flange 18 and the free edge of the bottom part 14 includes a carrier flange 20. The package 10 is configured so that the sealing flange 18 and the carrier flange 20 come together when the package 10 is closed. A double-sided adhesive 22 is disposed on the carrier flange 20 to provide a mechanism for selectively joining the sealing flange 18 to the carrier flange 20 to seal the package 10. The double-sided adhesive 22 of this embodiment has sufficient adhesive strength to make it difficult for the sealed flanges to be separated from one another without causing damage that is evident through visual inspection of the package 10. The doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com