Building system and components therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

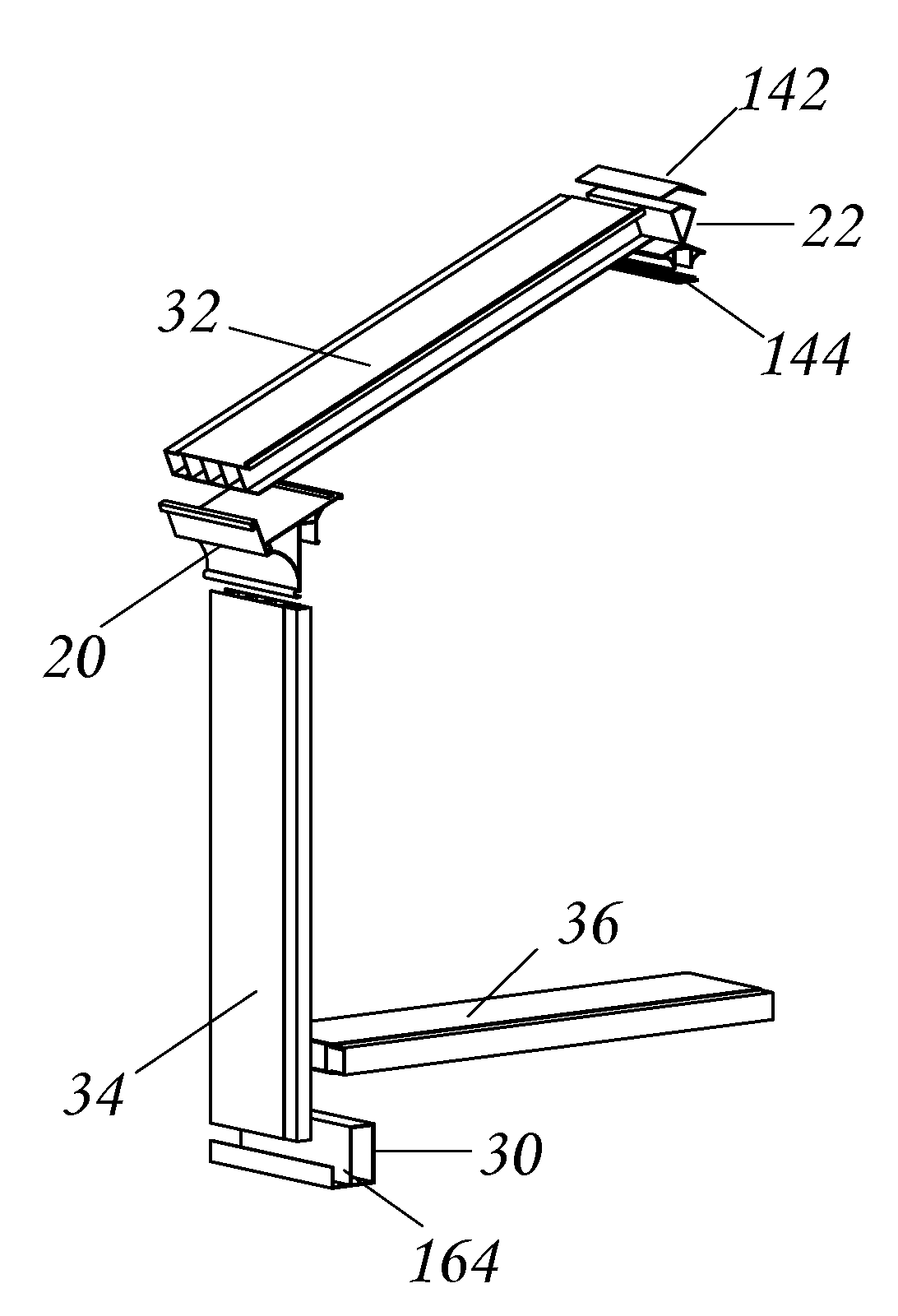

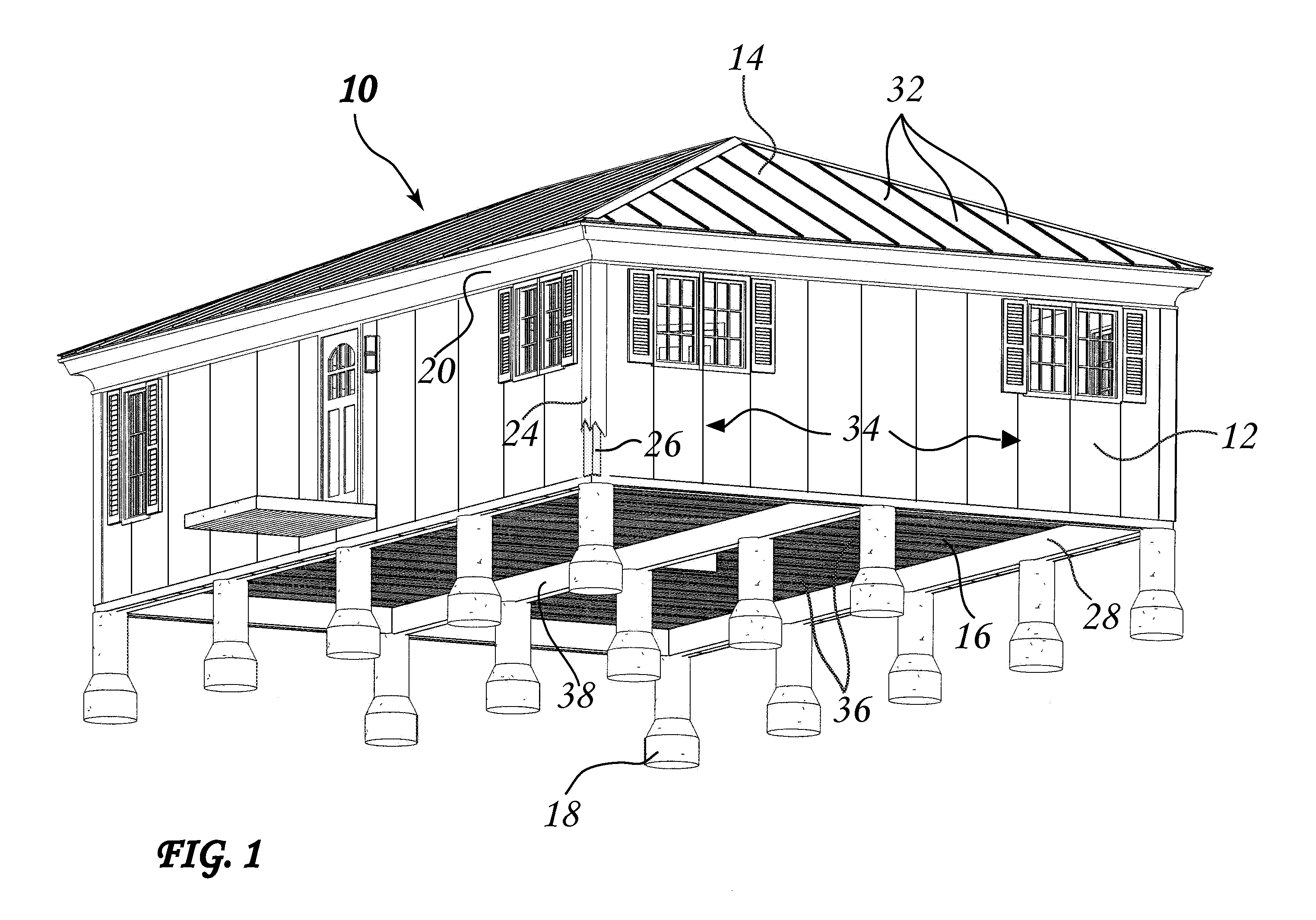

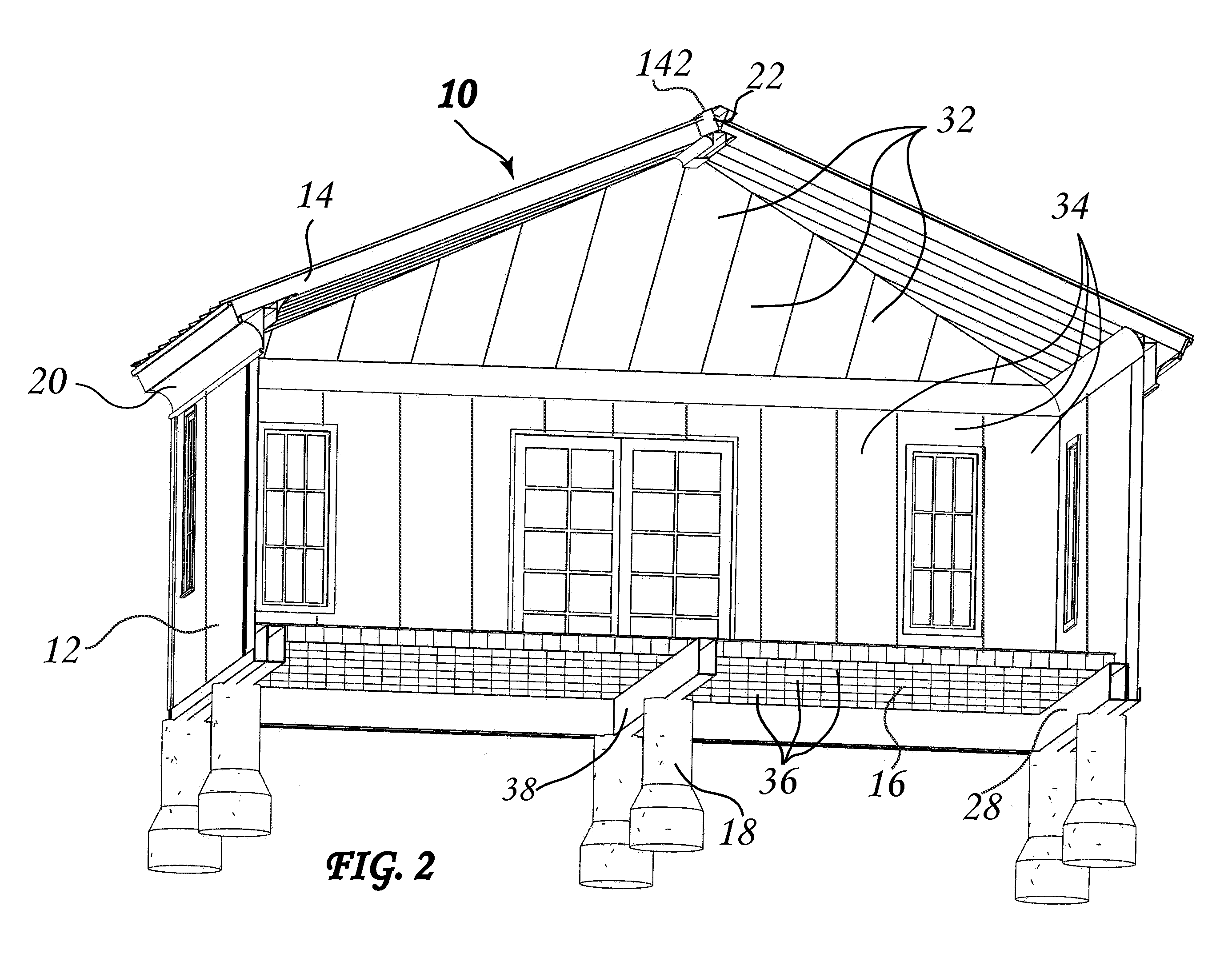

[0044]FIGS. 1 and 2 illustrate a typical building 10 made in accordance with the present invention having walls 12, a roof 14, floor 16 and foundation column supports 18. As seen in the sectional view of FIG. 2, the building 10 includes a soffit and fascia tie beam 20 connecting the roof 14 and walls 12, a structural ridge 22 at the top of the building 10 at the upper junction of the roof 14, an exterior corner cap 24, a corner connector 26, and sill beam 28 attached to the column supports 18. The roof 14 is made of a plurality of interconnected panels 32. Similarly the walls 12 are made of a plurality of interconnected panels 34. The floor 16 is also made with a plurality of interconnected panels 36. The corner connector 26 connects the wall panels 34 at the outside and inside corners of the wall junctions. The exterior corner cap 24 is positioned over the corner connector 26. An additional structural beam 38 is centrally located in the building 10 to support the floor 16 on the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com