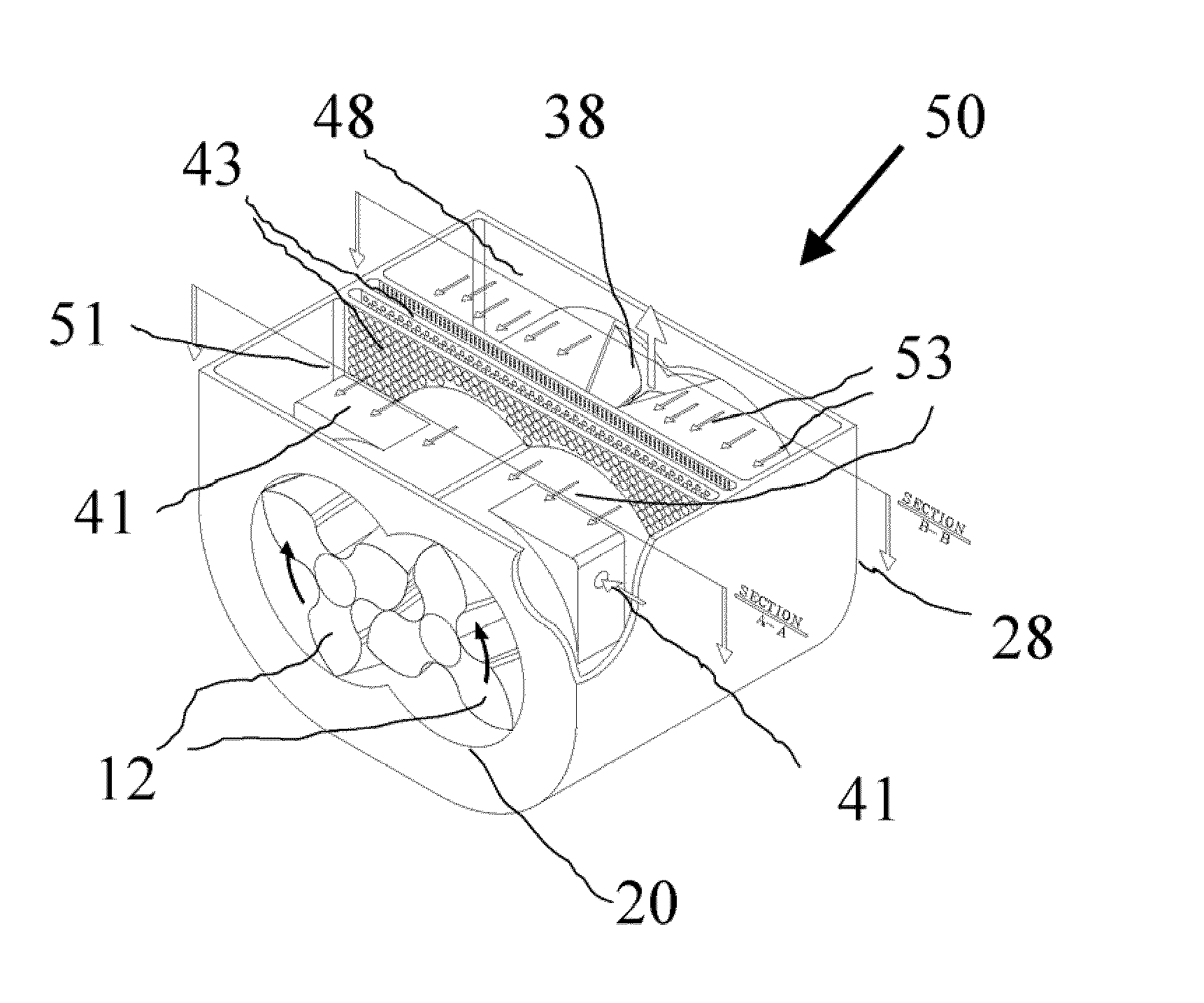

Roots supercharger with a shunt pulsation trap

a supercharger and pulsation trap technology, applied in the direction of machines/engines, liquid fuel engines, rotary/oscillating piston pump components, etc., can solve the problems of pulsation control, huge pressure and flow pulsations, and impede the expansion of commercial applications, etc., to achieve compact size, less noise, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0039]Although specific embodiments of the present invention will now be described with reference to the drawings, it should be understood that such embodiments are examples only and merely illustrative of but a small number of the many possible specific embodiments which can represent applications of the principles of the present invention. Various changes and modifications obvious to one skilled in the art to which the present invention pertains are deemed to be within the spirit, scope and contemplation of the present invention as further defined in the appended claims.

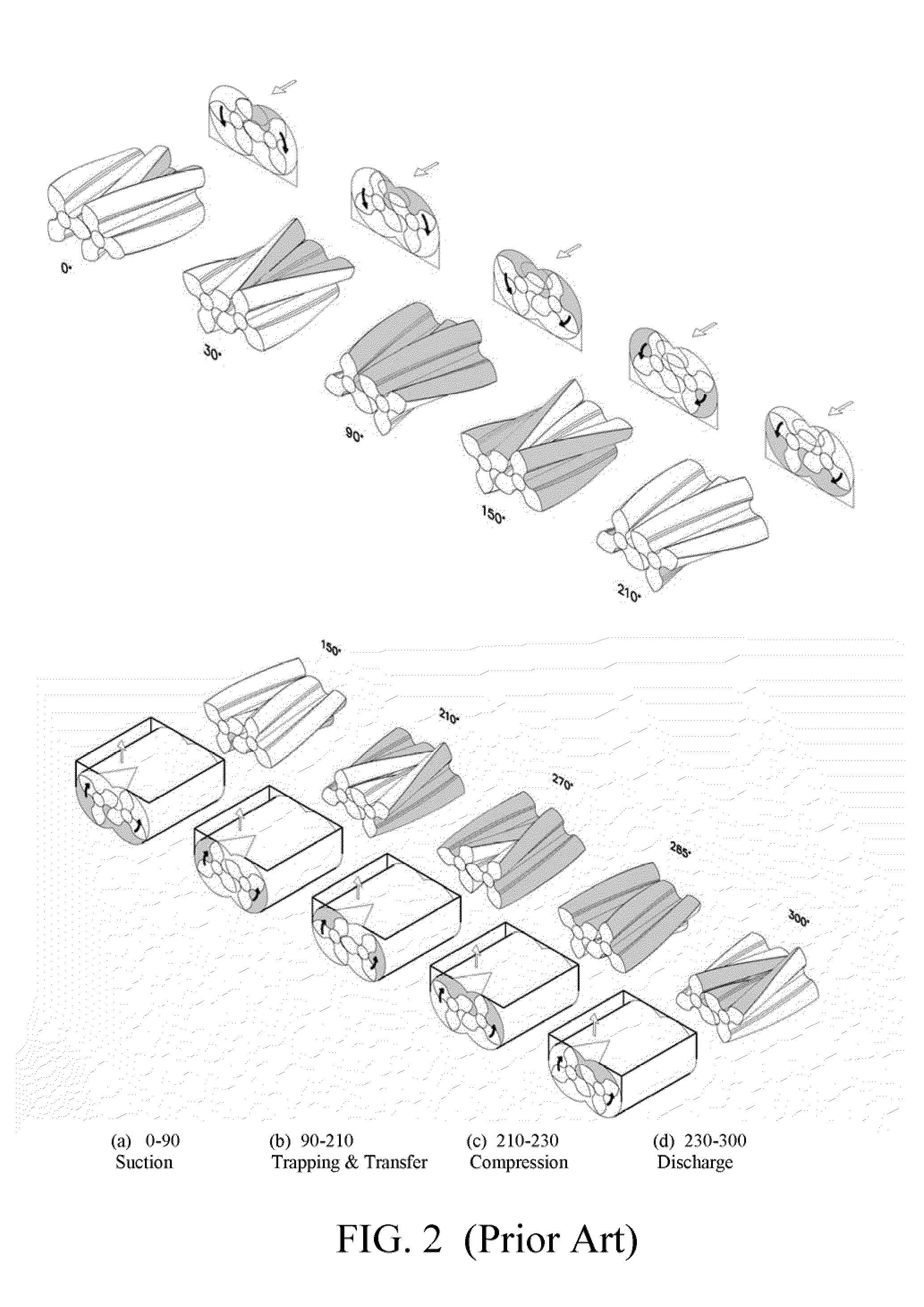

[0040]It should also be pointed out that though drawing illustrations and description are devoted to a helical three-lobe Roots supercharger in the present invention, the principle can be applied to other types of rotary supercharger with different numbers of lobes such as four-lobed, five-lobed or six lobed, etc. as long as both rotors have the same number of lobes. The principle can also be applied to either gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com