Vacuum pump with ventilating means

a vacuum pump and ventilating technology, applied in the field of vacuum pumps, can solve problems such as negative consequences, and achieve the effect of more operational stability of vacuum pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

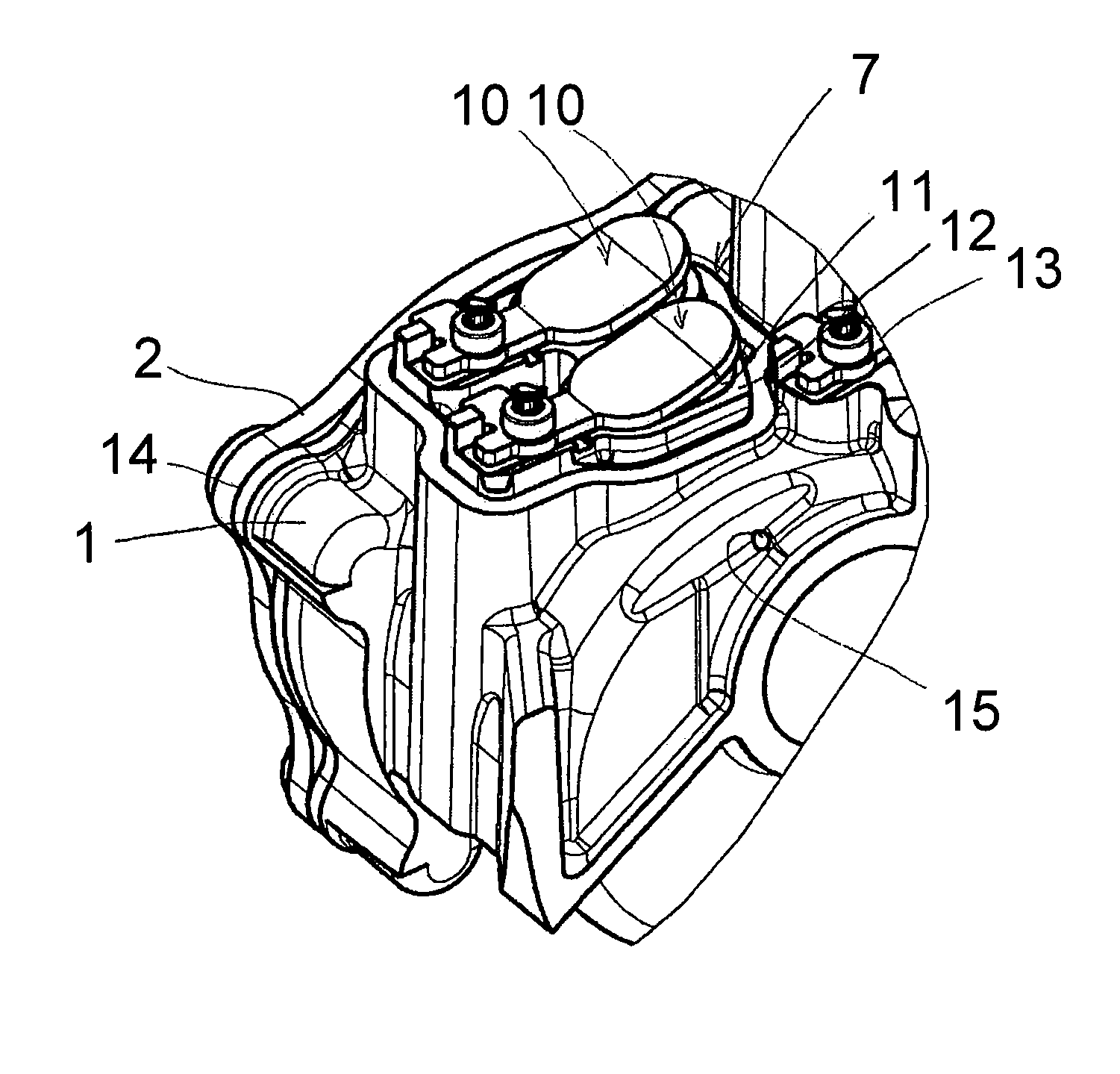

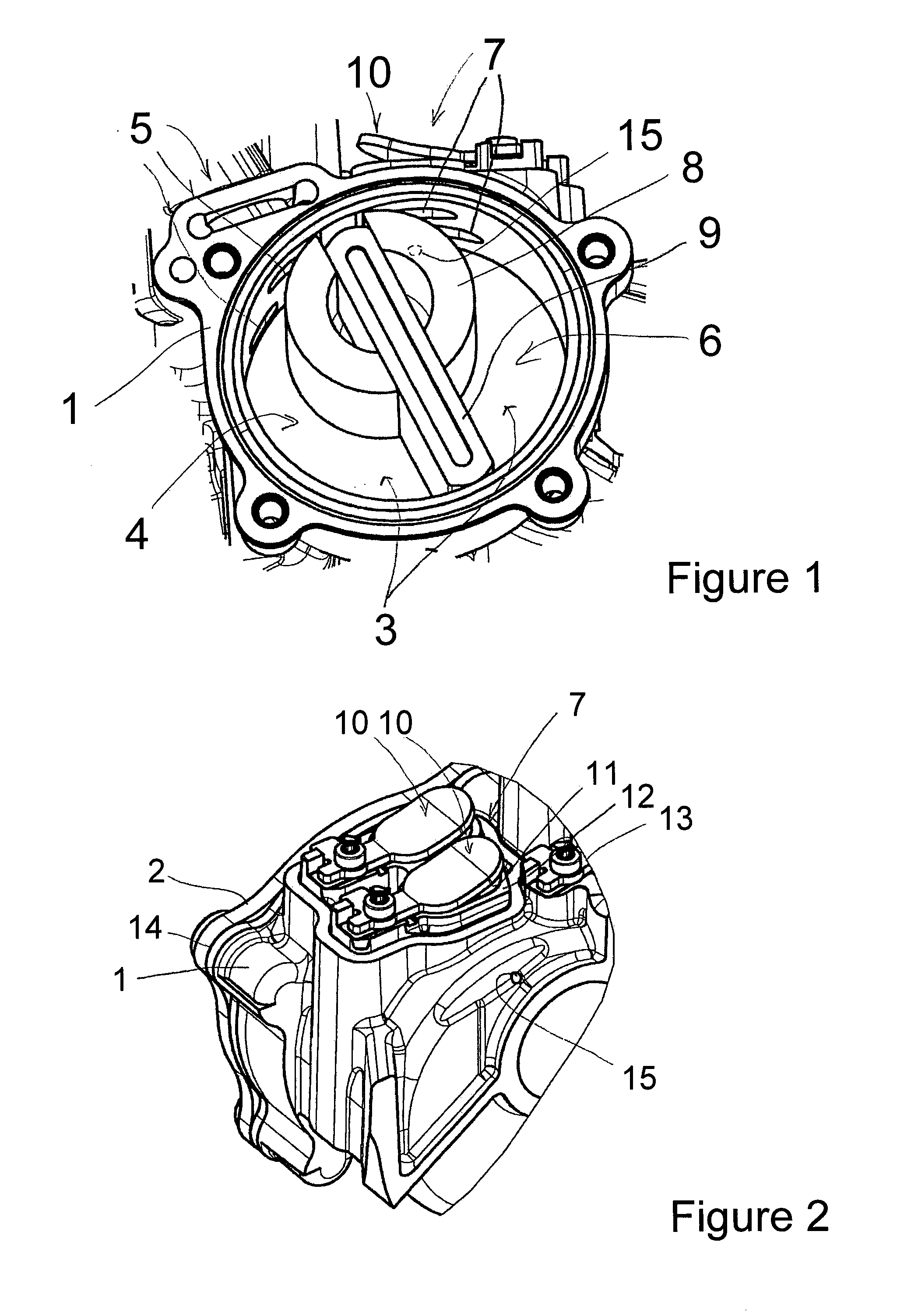

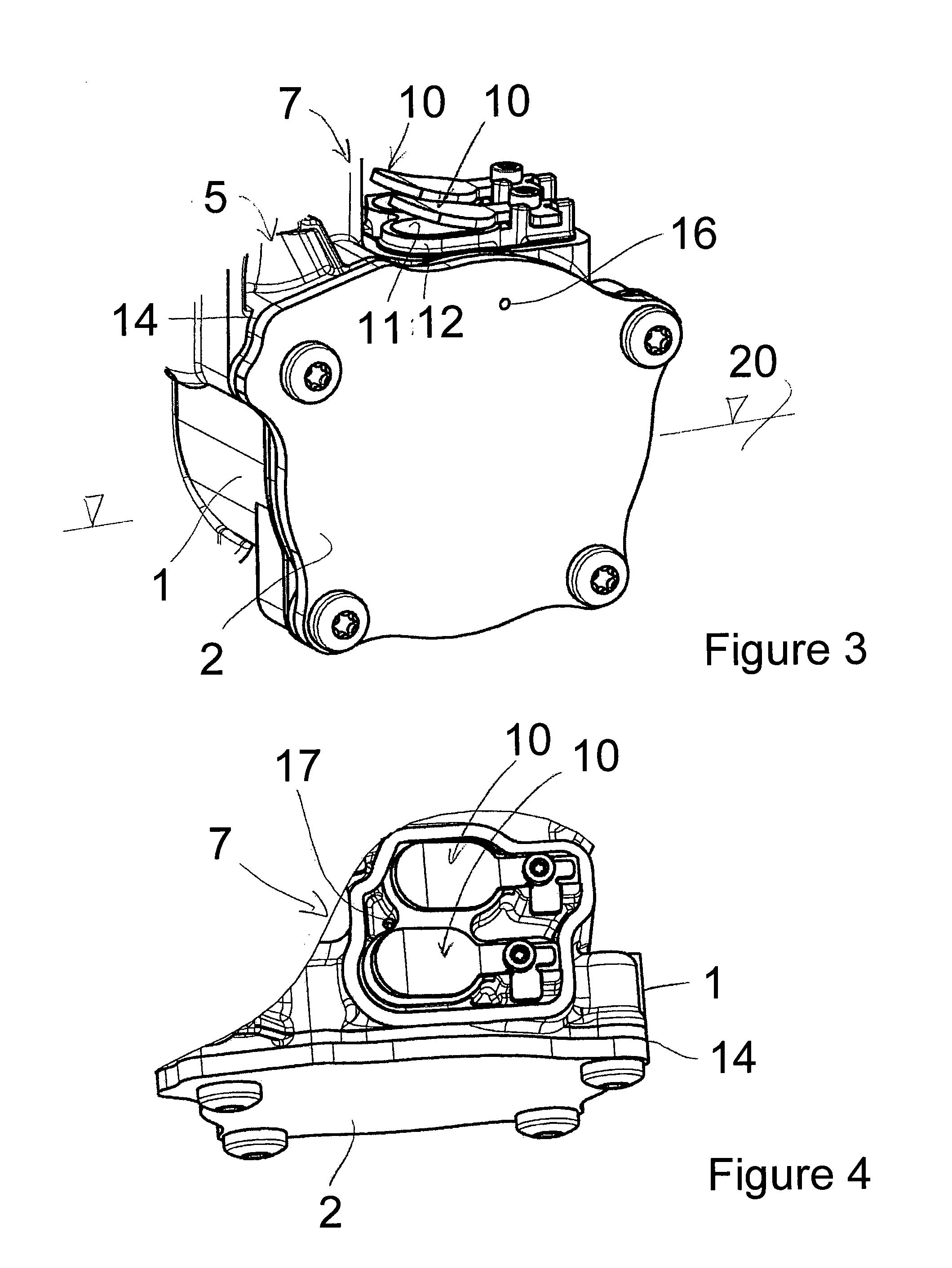

[0028]FIG. 1 shows a vacuum pump of a first exemplary embodiment, in a perspective view onto a housing 1 of the vacuum pump. A housing cover is removed, such that a delivery chamber 3 which is surrounded by the housing 1 and the housing cover when they are assembled is exposed. A delivery member comprising a rotor 8 and a vane 9 is movably arranged in the delivery chamber 3. The vacuum pump is for example embodied as a vane cell pump, wherein a single-vane vacuum pump serves as an example. When the delivery member 8, 9 is rotary-driven anti-clockwise, a low-pressure region 4 comprising a working inlet 5 and a high-pressure region 6 comprising a working outlet 7 are formed in the delivery chamber 3. The vacuum pump is connected to an assembly, for example a brake booster of a motor vehicle, via the working inlet 5 in order to supply the assembly with a negative pressure. When the delivery member 8, 9 is rotary-driven, air is suctioned into the low-pressure region 4 through the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com