Method for fabricating semiconductor devices using stress engineering

a technology of stress engineering and semiconductor devices, applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems of high current during operation and correspondingly faster device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The following embodiments are described in sufficient detail to enable those skilled in the art to make and use the invention. It is to be appreciated that other embodiments would be evident based on the present disclosure, and that system, process, or mechanical changes may be made without departing from the scope of the present invention.

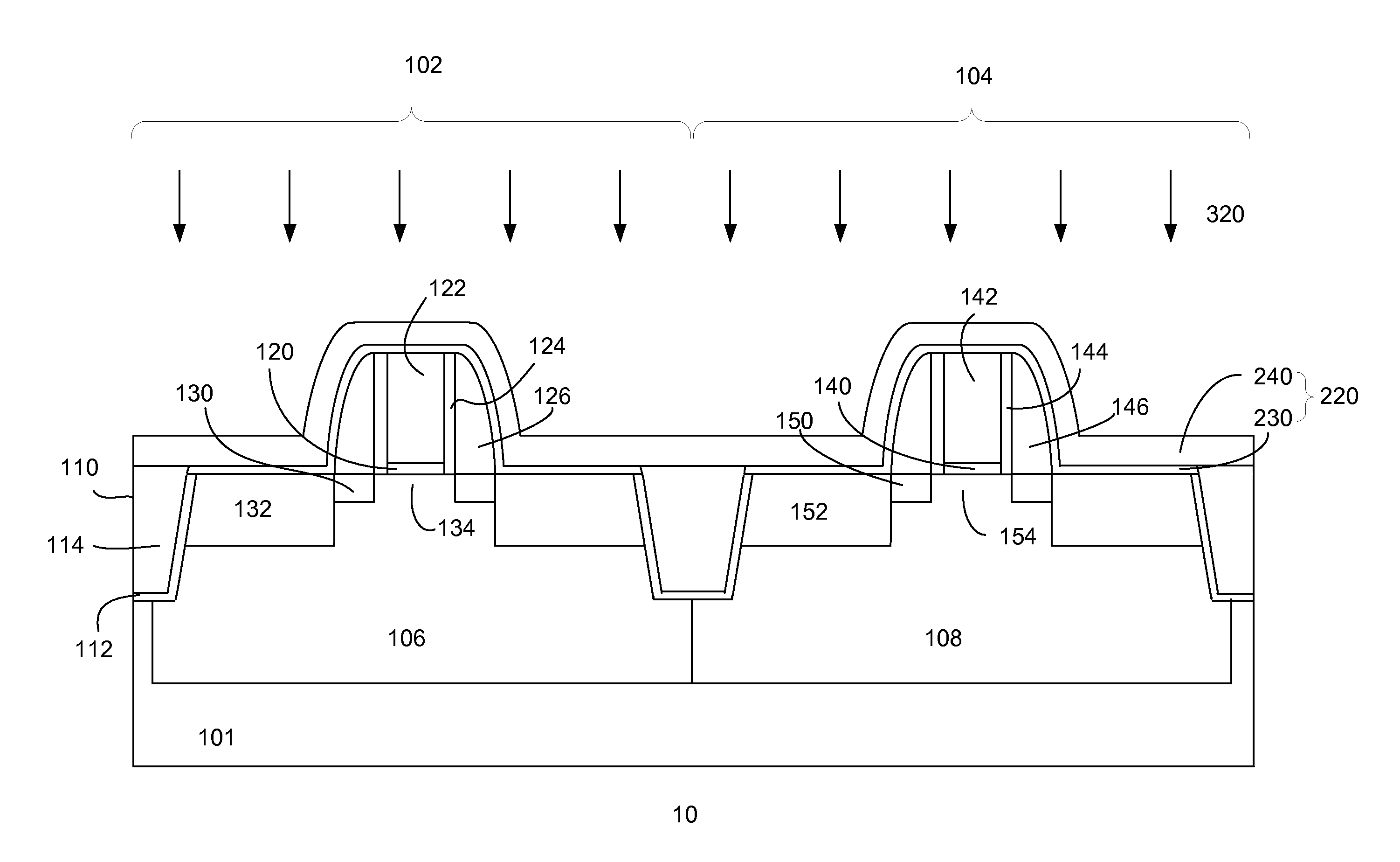

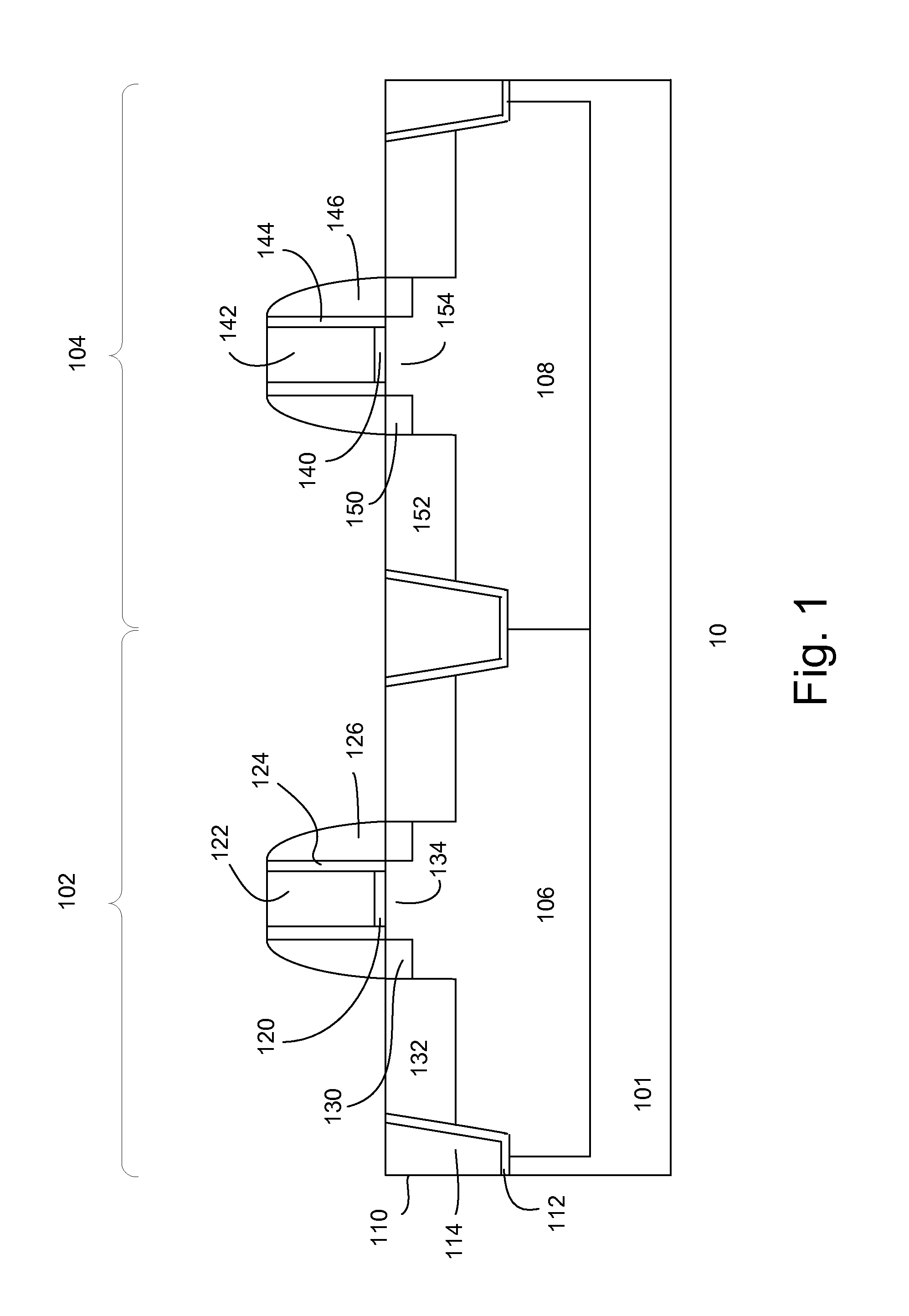

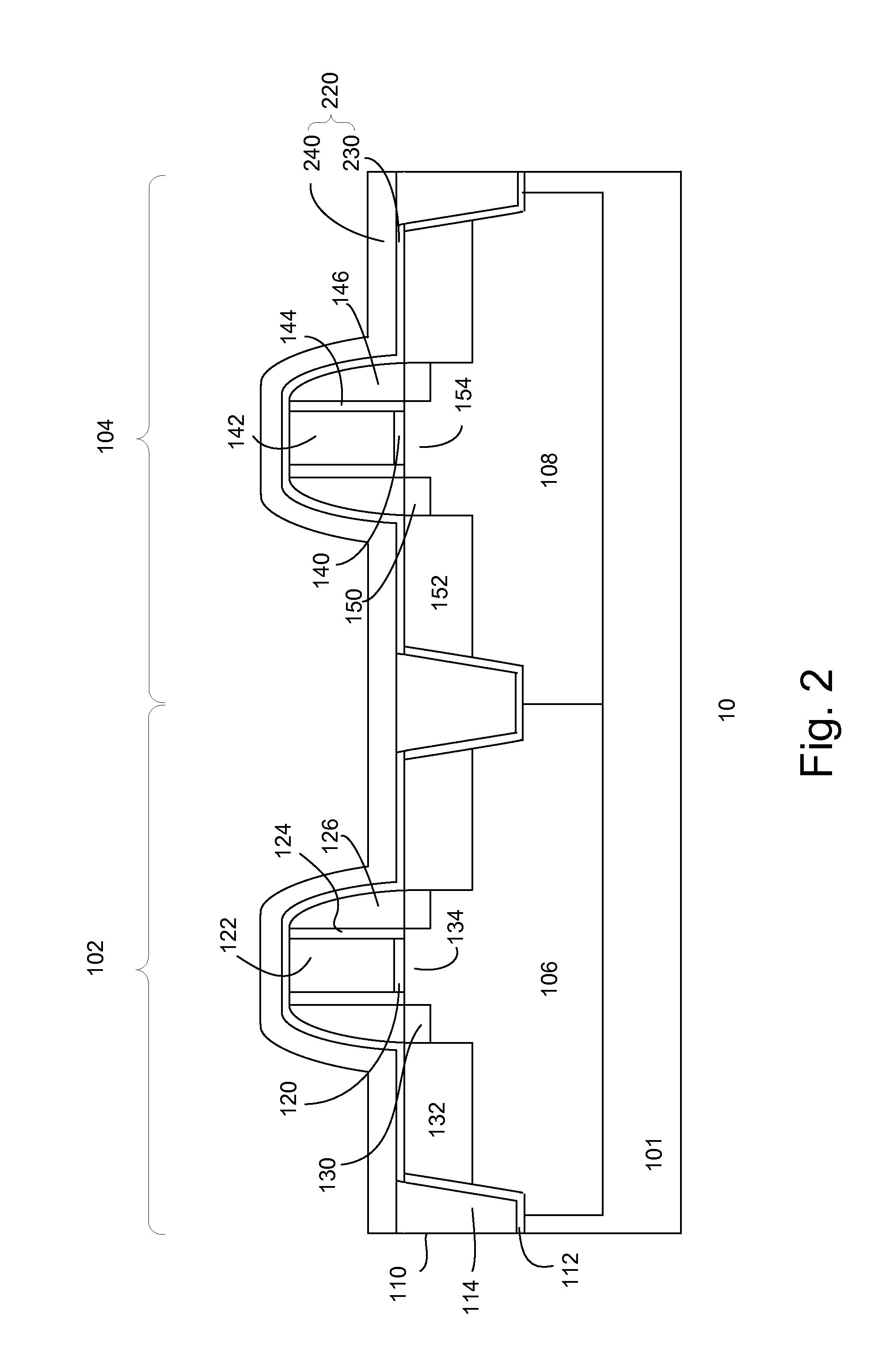

[0013]FIGS. 1 to 5 are cross-sectional views illustrating process steps for fabricating Metal Oxide Field Effect Transistors (MOSFET) in accordance with one embodiment of the invention. It should be noted, however, that embodiments of the invention are described in the context of fabricating MOSFETs for illustrative purposes only and that the invention may also be applicable to the fabrication of other semiconductor devices such as but not limited to multi-gate transistors, annular gate transistors and high voltage transistors.

[0014]Additionally, it is to be understood that a plurality of conventional processes that are well known in the art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com