Co2 refrigeration system for ice-playing surfaces

a refrigeration system and ice-playing technology, applied in water-skiing, sports equipment, ski bindings, etc., can solve the problems of high flammability of refrigerants, environmental harm, and high risk of local safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

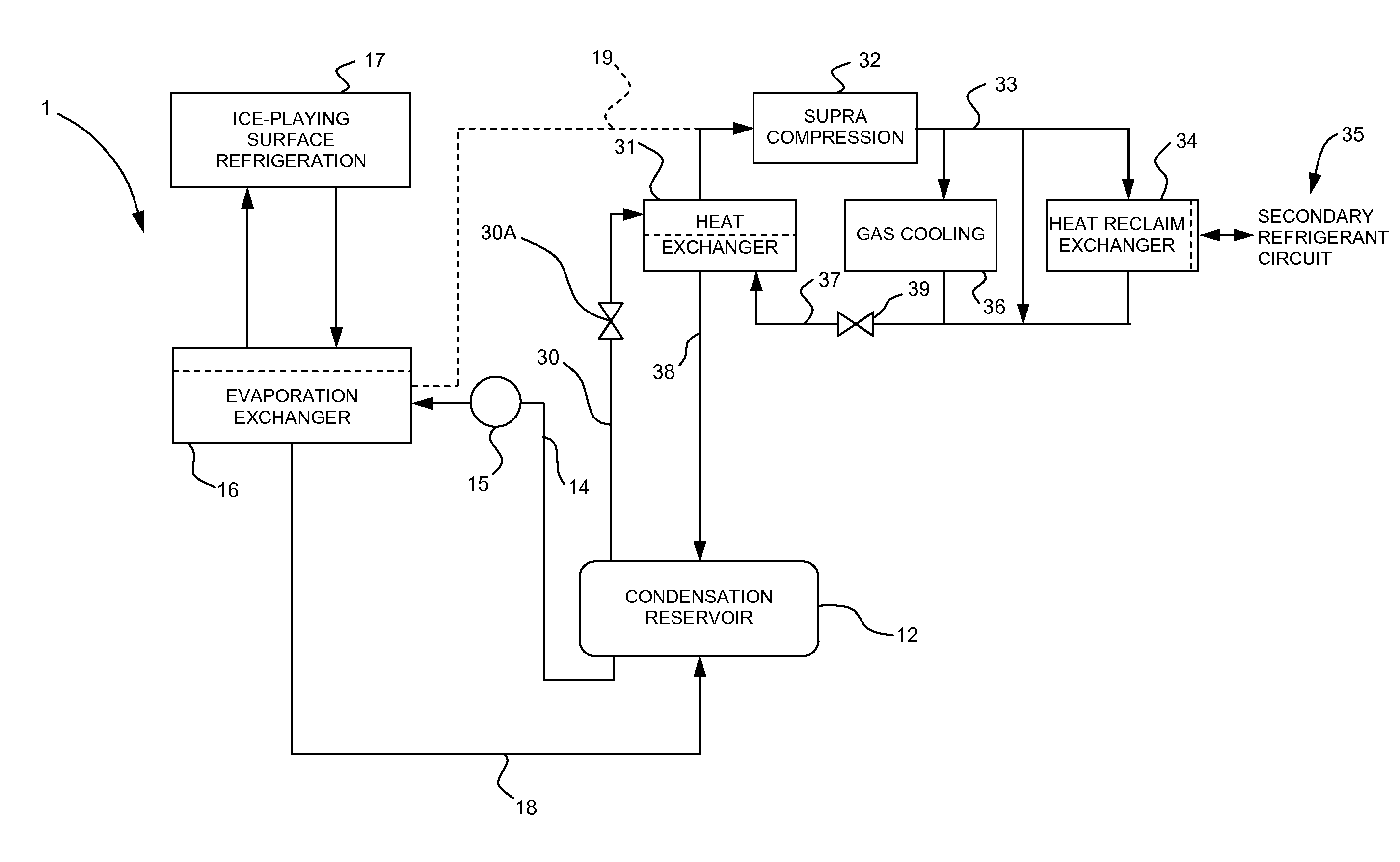

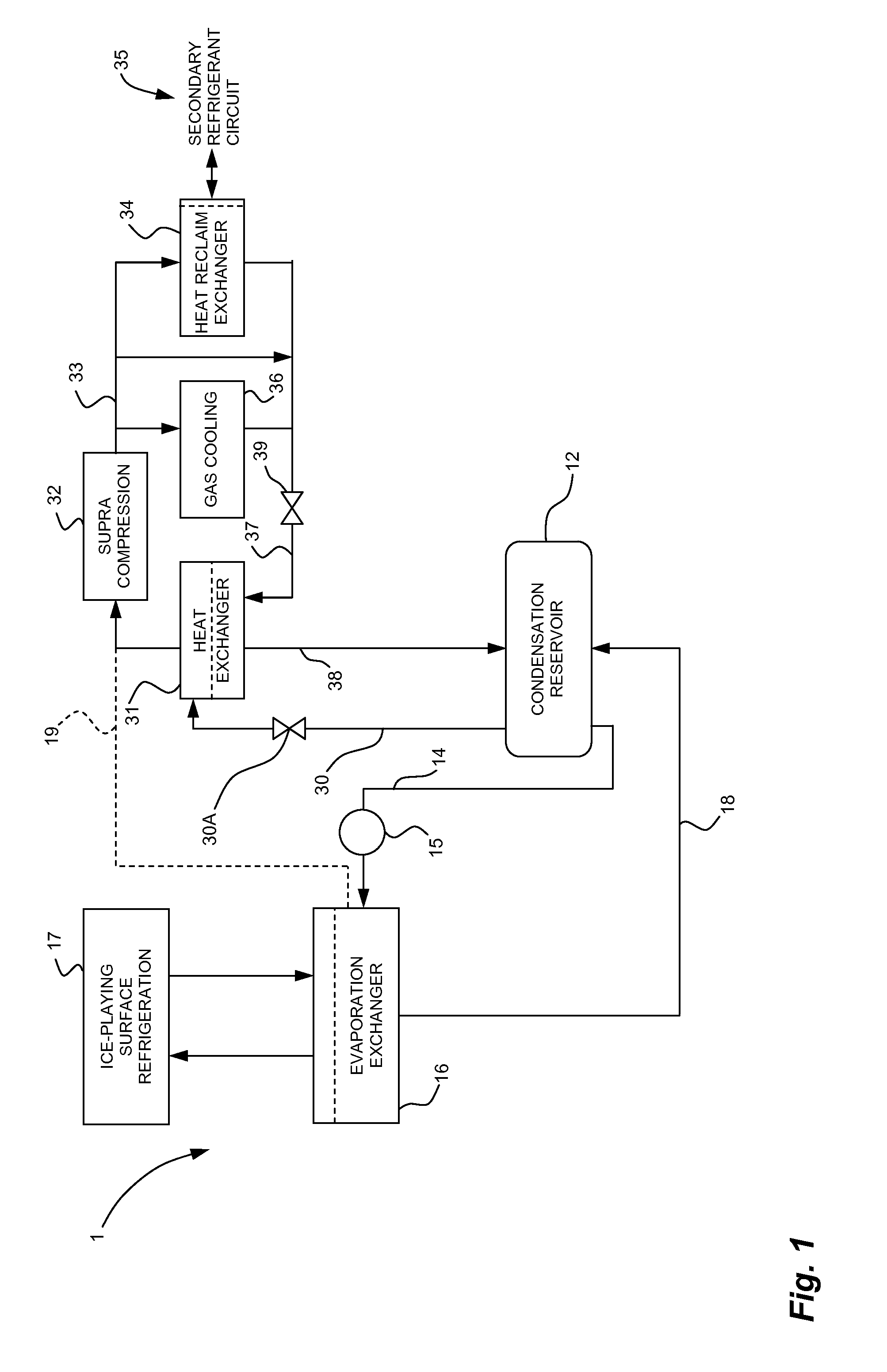

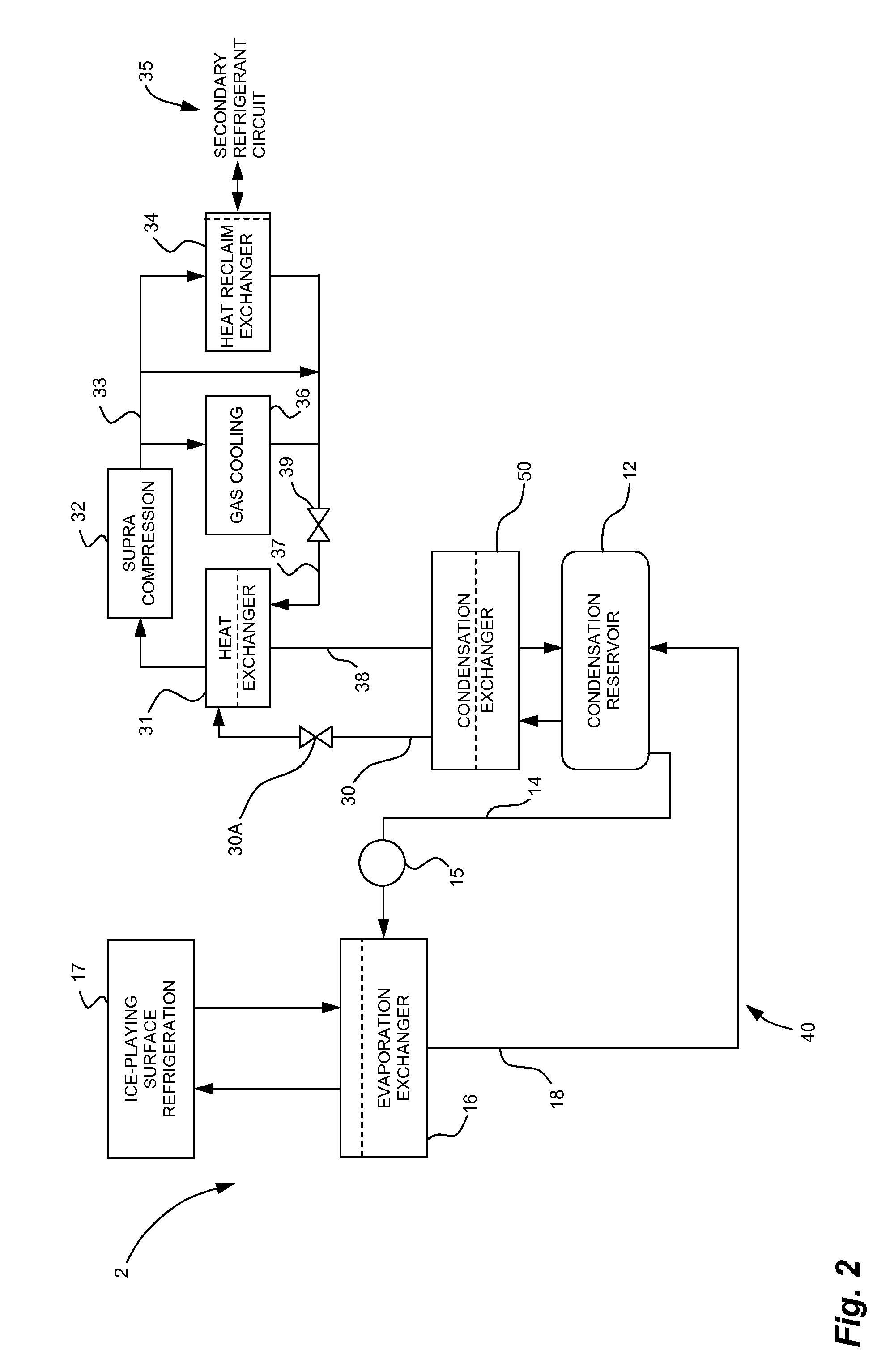

[0015]Referring to FIG. 1, a CO2 refrigeration system in accordance with an embodiment is illustrated at 1. The CO2 refrigeration system 1 has a CO2 refrigeration circuit comprising a CO2 condensation reservoir 12. The condensation reservoir 12 accumulates CO2 refrigerant in a liquid and gaseous state, and may be in a heat-exchange relation with a closed condensation circuit that absorbs heat from the CO2 refrigerant, with examples given hereinafter.

[0016]Line 14 directs CO2 refrigerant from the condensation reservoir 12 to an evaporation stage via pump(s) or expansion valve(s). As is shown in FIG. 1, the CO2 refrigerant is supplied in a liquid state by the condensation reservoir 12 into line 14. The pump 15 ensures a suitable flow of liquid CO2 refrigerant to the evaporation exchanger 16. In some instances, expansion valve(s) 15 may be used to control the pressure of the CO2 refrigerant, which is then fed to the evaporation exchanger 16. Any appropriate means may be used to put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com