Laminate and method for separating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

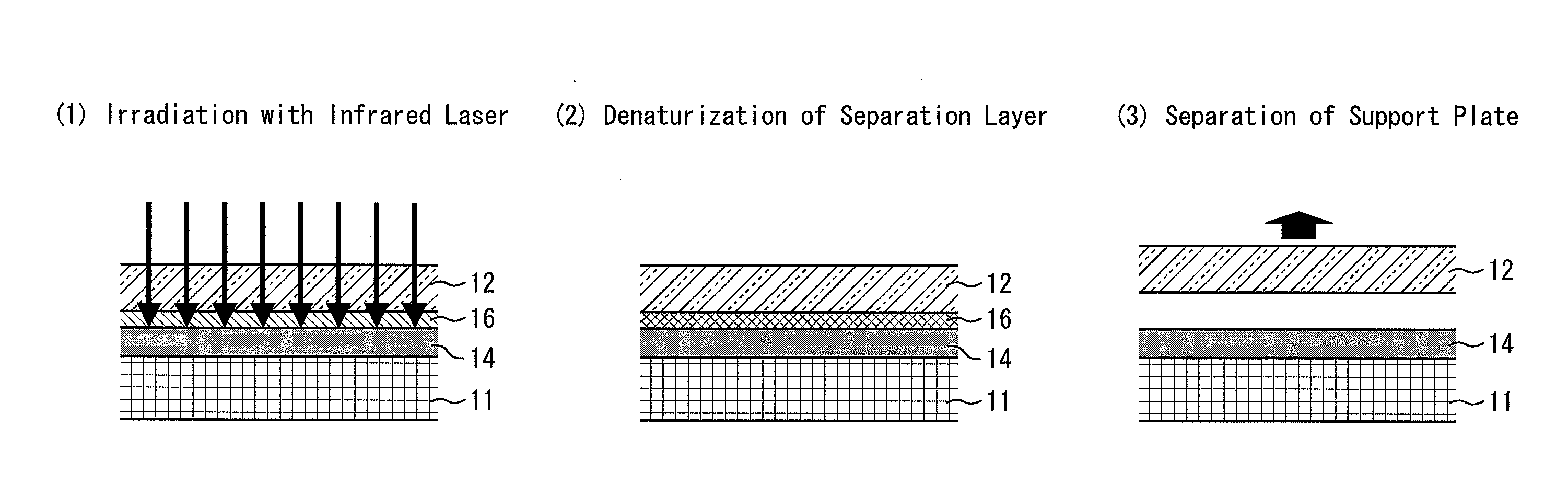

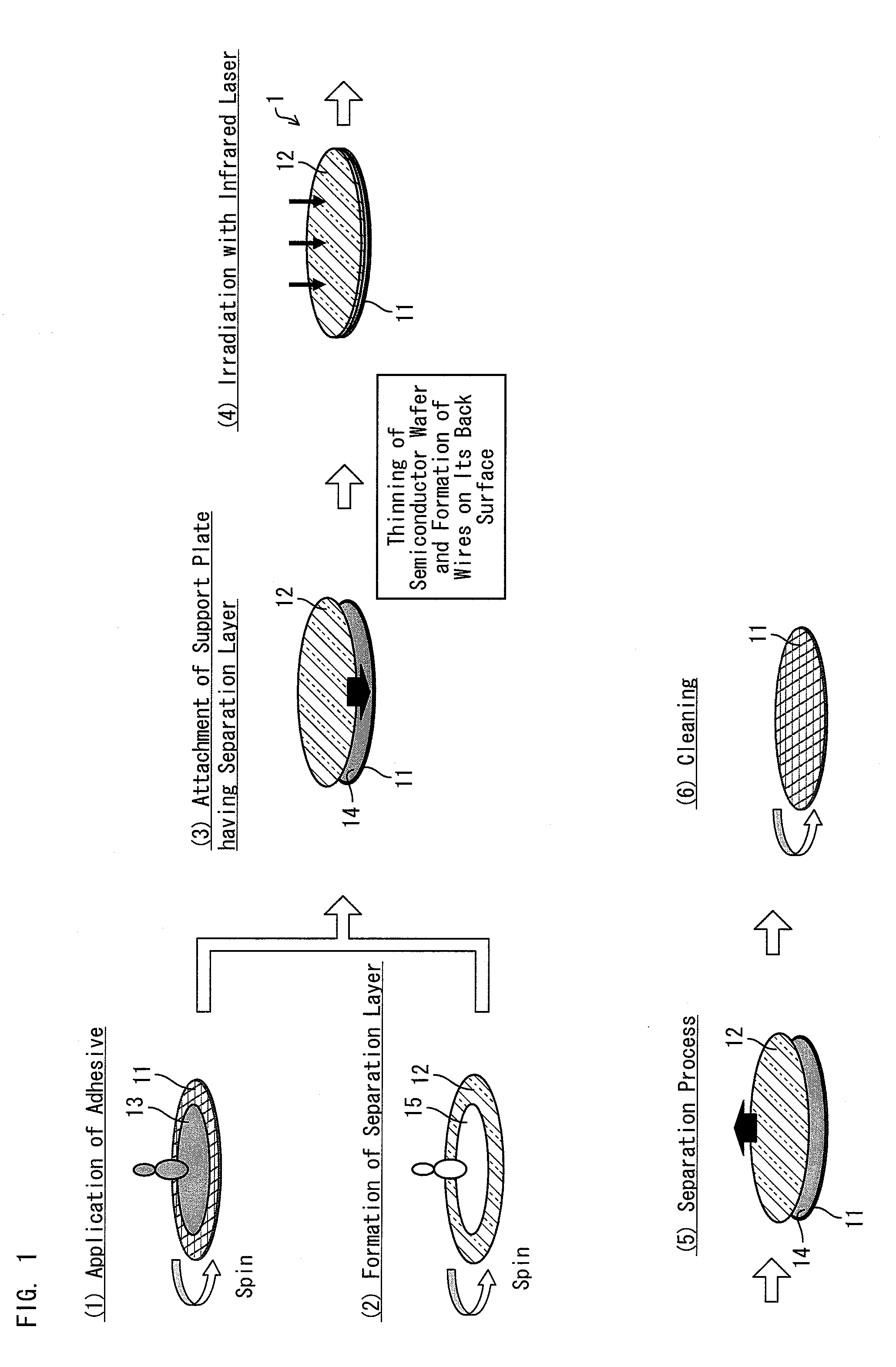

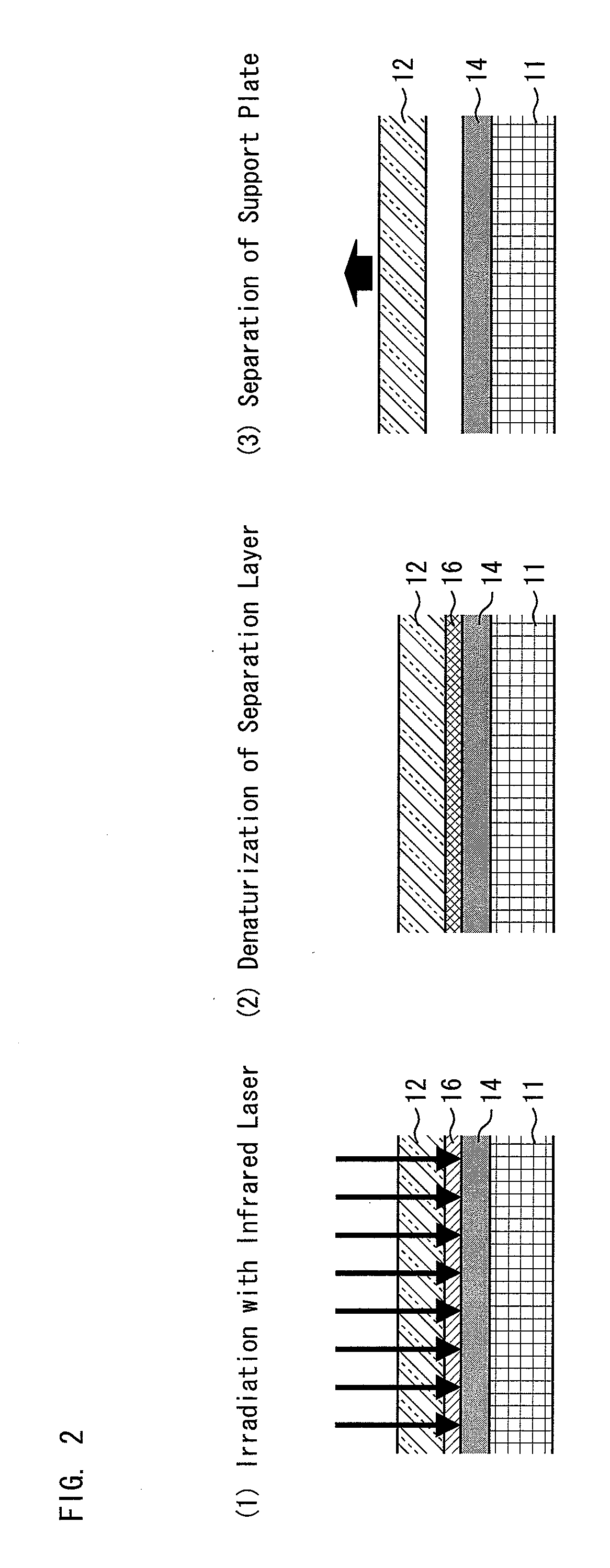

Method used

Image

Examples

examples

(Preparation of Laminate)

[0090]A laminate in Example 1 was prepared as follows. A tert-butylstyrene (TBST)-dimethylsiloxane copolymer having a siloxane structure, which is a copolymer of a repeating unit represented by Formula (3) below and a repeating unit represented by Formula (1) below (this copolymer is hereinafter referred to as Resin 1), was dissolved in PGMEA in such a manner that the content of the Resin 1 after dissolution was 20 weight %. Thus, a separation layer solution was obtained. An abundance ratio (molar ratio) of the repeating units in the Resin 1 was such that Formula (3): Formula (1)=1: 1. Weight-average molecular weight Mw of the Resin 1 was 8,000.

[0091]The separation layer solution was spin-applied onto a silicon wafer serving as a support plate in such a manner that the separation layer would have a thickness of 1 μm after baking the silicon wafer. Subsequently, the silicon wafer was heated in a stepwise manner for 1 min at 100° C., 160° C. and 220° C. so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com