Method of evaluating a clamping portion of an electric wire and a terminal, and device for evaluating the clamping portion

a technology of clamping portion and evaluation device, which is applied in the direction of testing/measuring connectors, line/current collector details, instruments, etc., can solve the problems of mechanical connection performance and electric connection performance differences, and achieve easy evaluation, good clamping portion quality, and easy measurement of terminal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Hereinafter, embodiments of the present invention will be described with reference to the drawings.

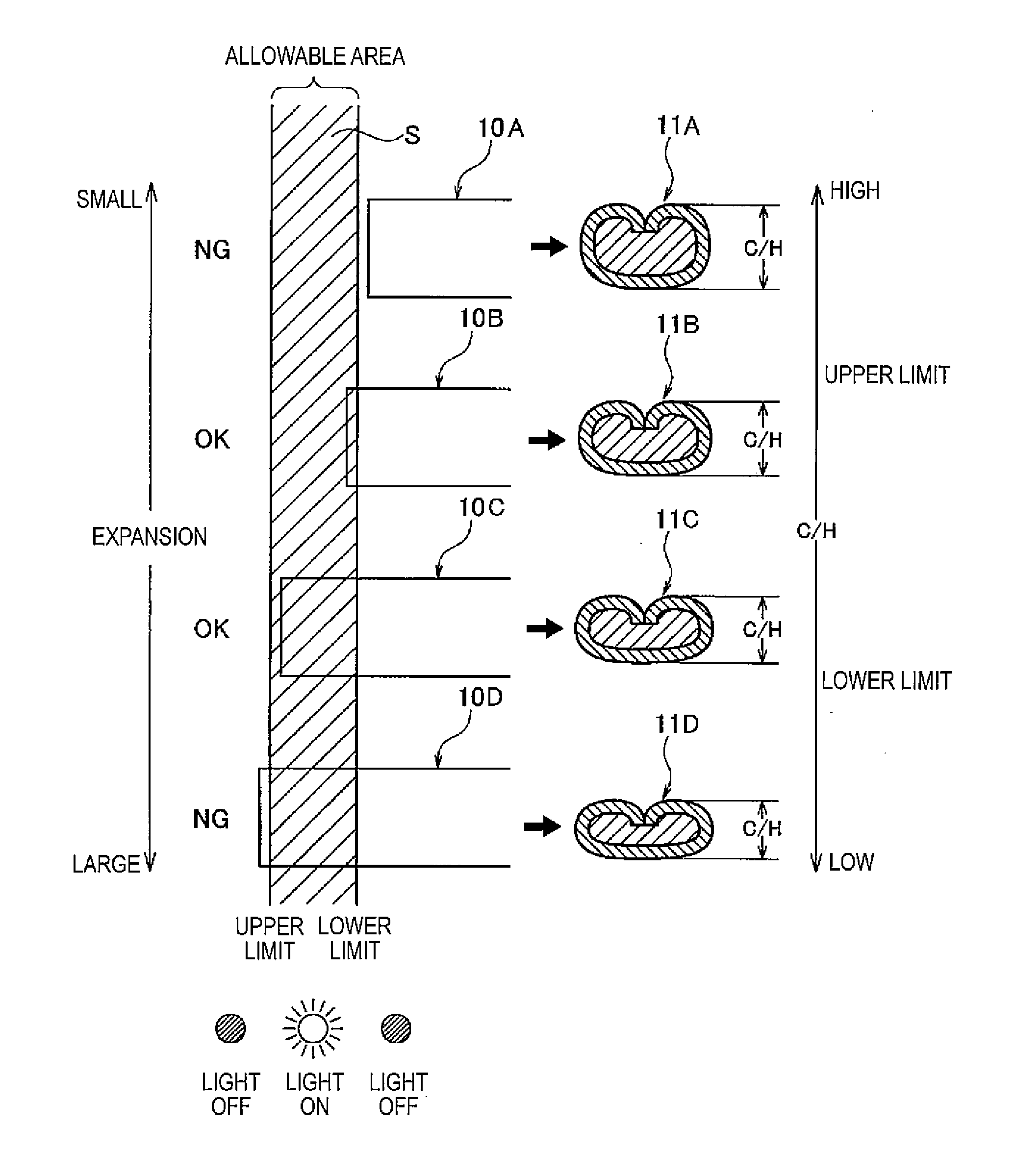

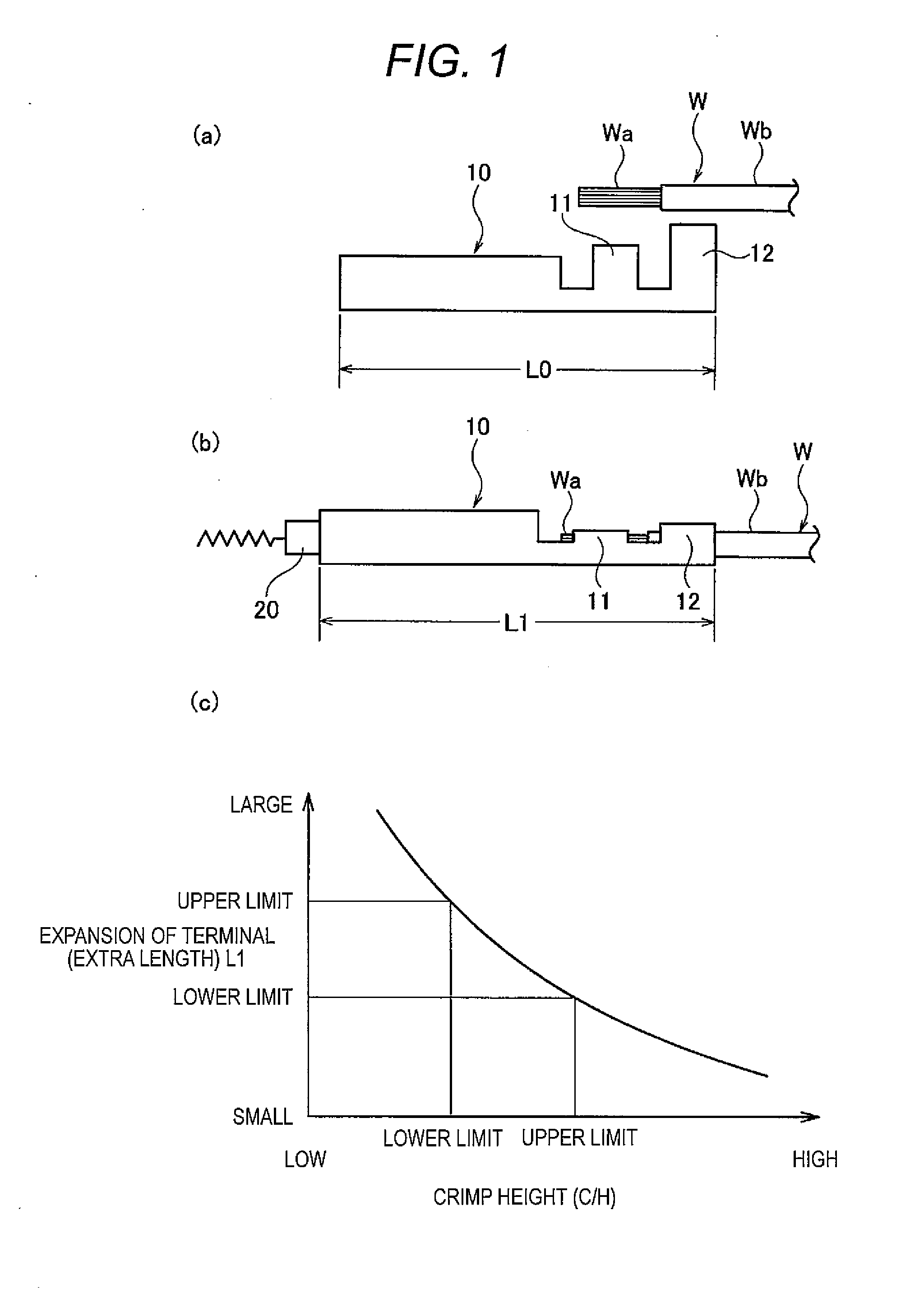

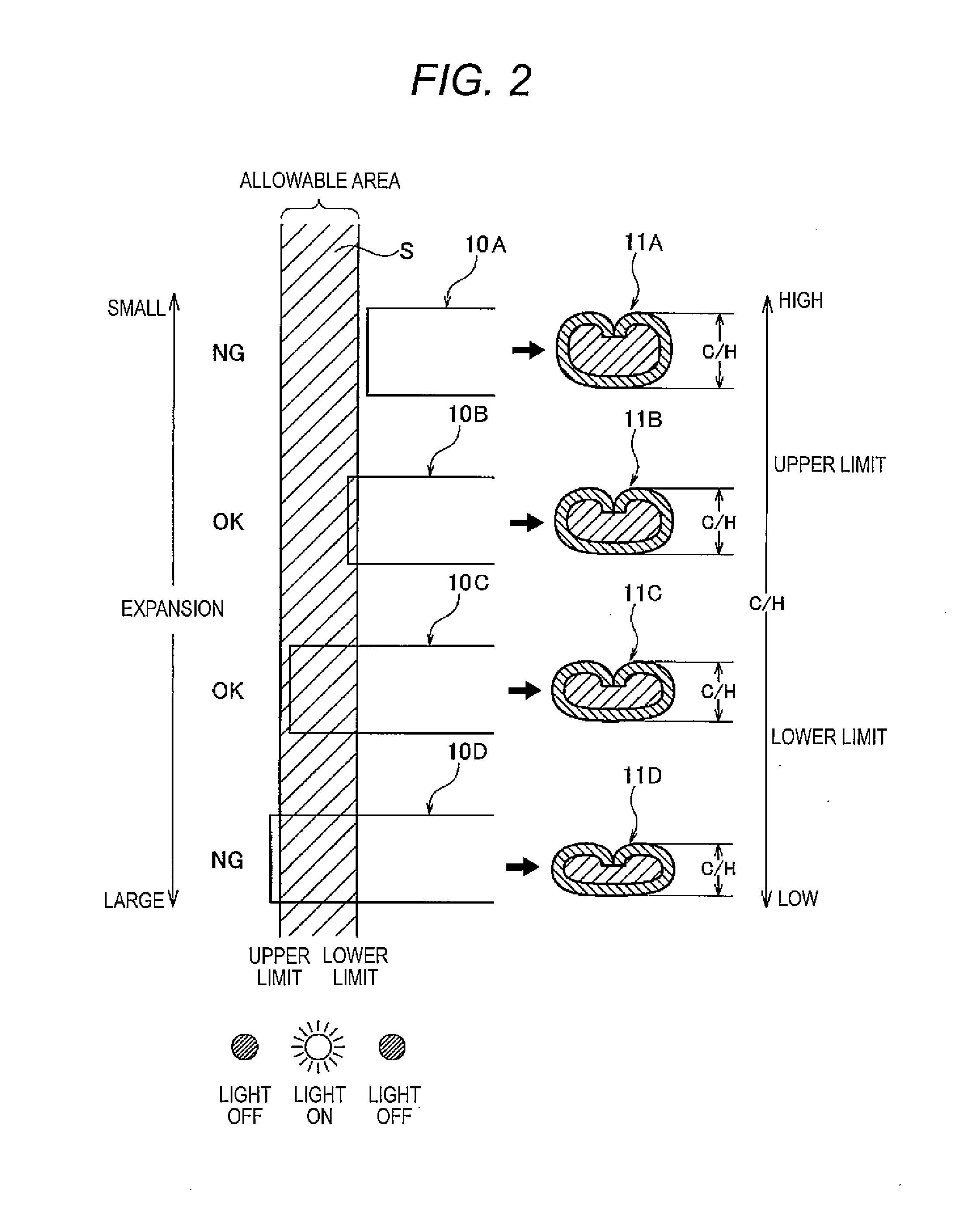

[0022]FIG. 1 is an illustrative diagram of an evaluation method according to an embodiment of the present invention, in which FIG. 1(a) is a side view illustrating a state before a terminal and an electric wire are crimped onto each other, FIG. 1(b) is a side view illustrating a state after the terminal and the electric wire are crimped onto each other, and FIG. 1(c) is a characteristic diagram illustrating a relationship between a crimp height and the expansion of the terminal due to clamping. The configuration of a terminal 10 and the configuration of an electric wire W are identical with those in FIG. 4, and therefore, their description will be omitted.

[0023]In this embodiment, as illustrated in FIGS. 1(a) and 1(b), an overall length L0 of the terminal 10 before clamping are grasped in advance, and an overall length L1 of the terminal 10 after clamping is measured by a detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com