Lubricant supply system and method for controlling gearbox lubrication

a technology of lubricant supply system and gearbox, which is applied in the direction of mechanical equipment, gearing details, machines/engines, etc., can solve the problems of high pressure and unsafe pump operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

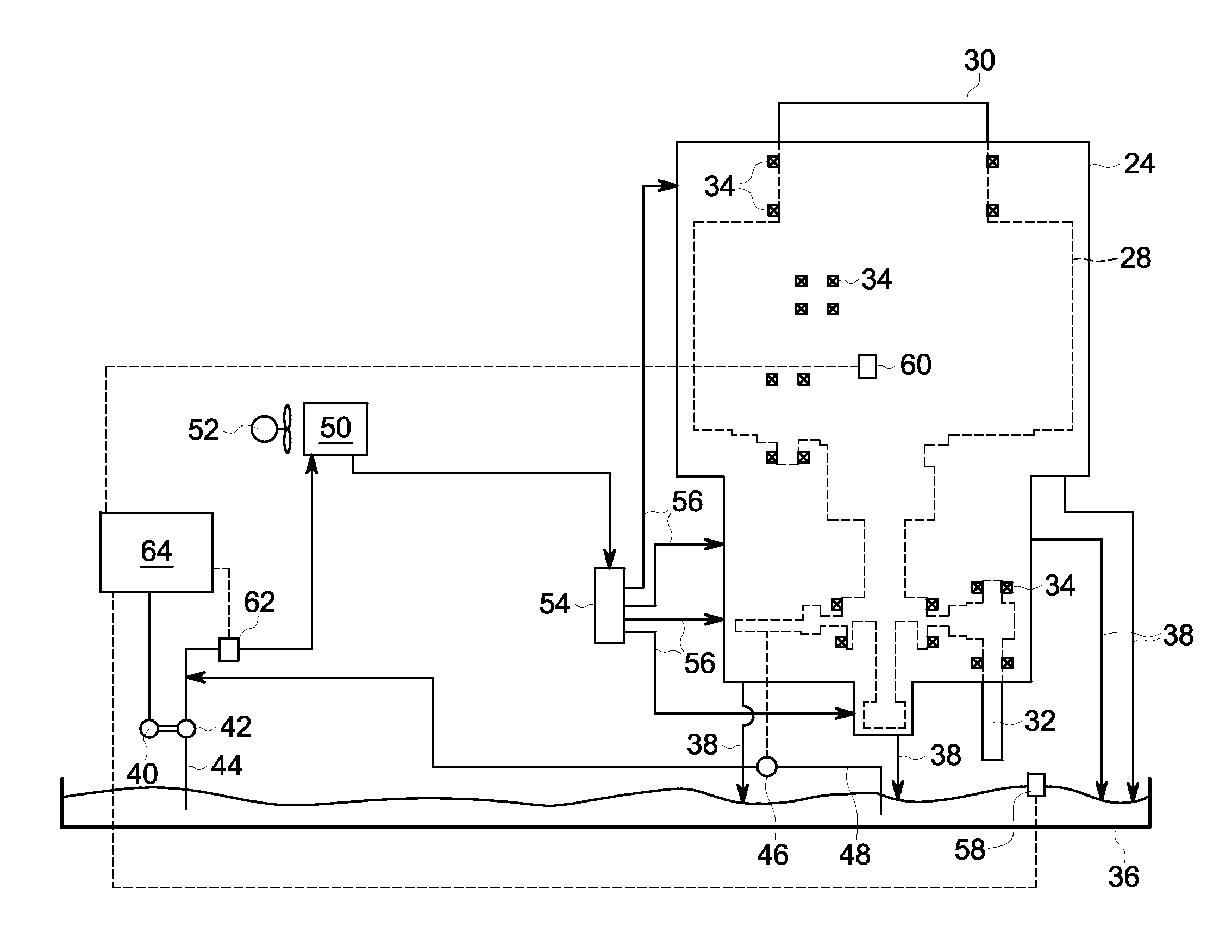

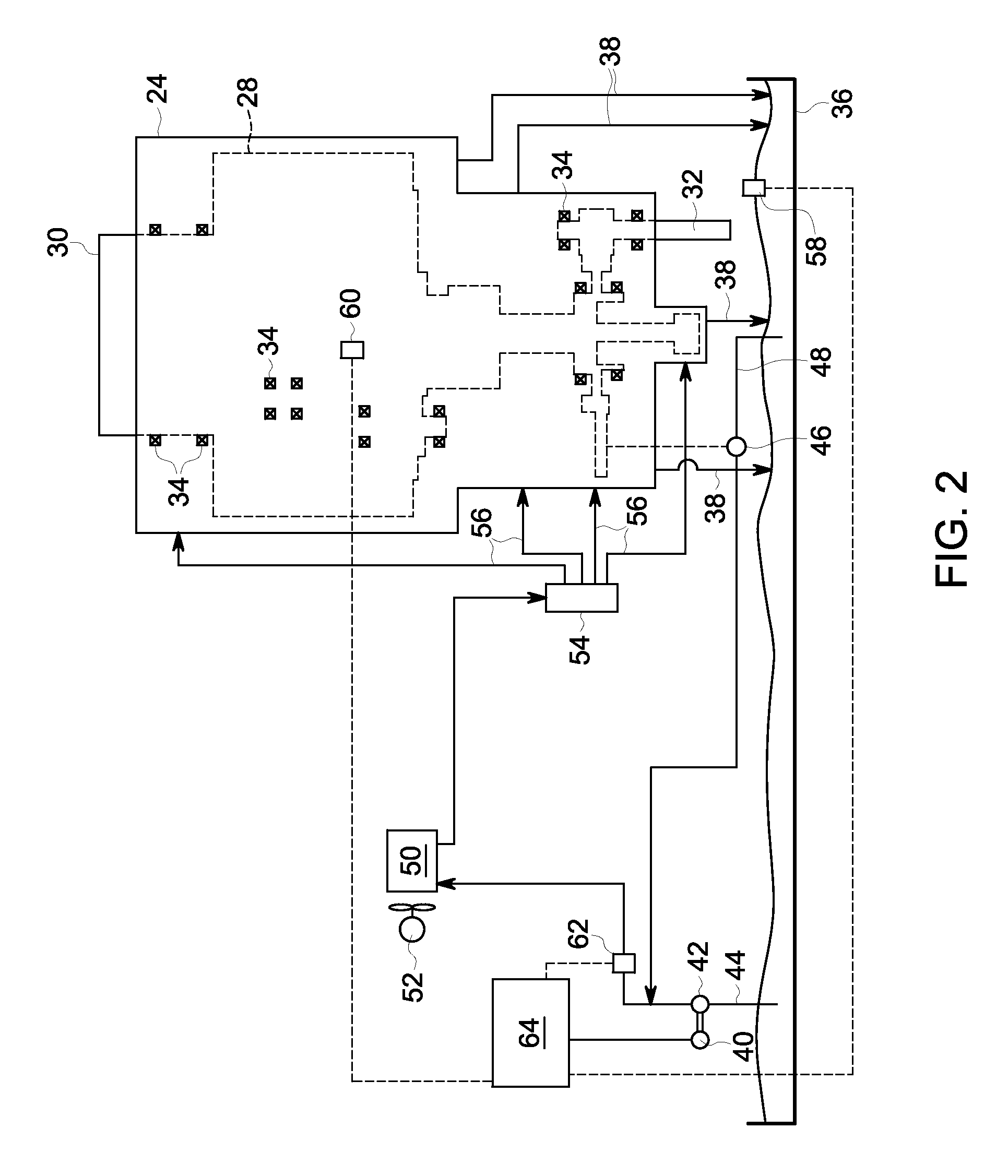

[0012]Referring to the drawings wherein identical reference numerals denote the same elements throughout the various views, embodiments of the invention relate to a lubricant supply system (generally shown in FIG. 2), e.g., for a wind turbine. Other embodiments relate to methods for controlling gearbox lubrication, e.g., for a wind turbine.

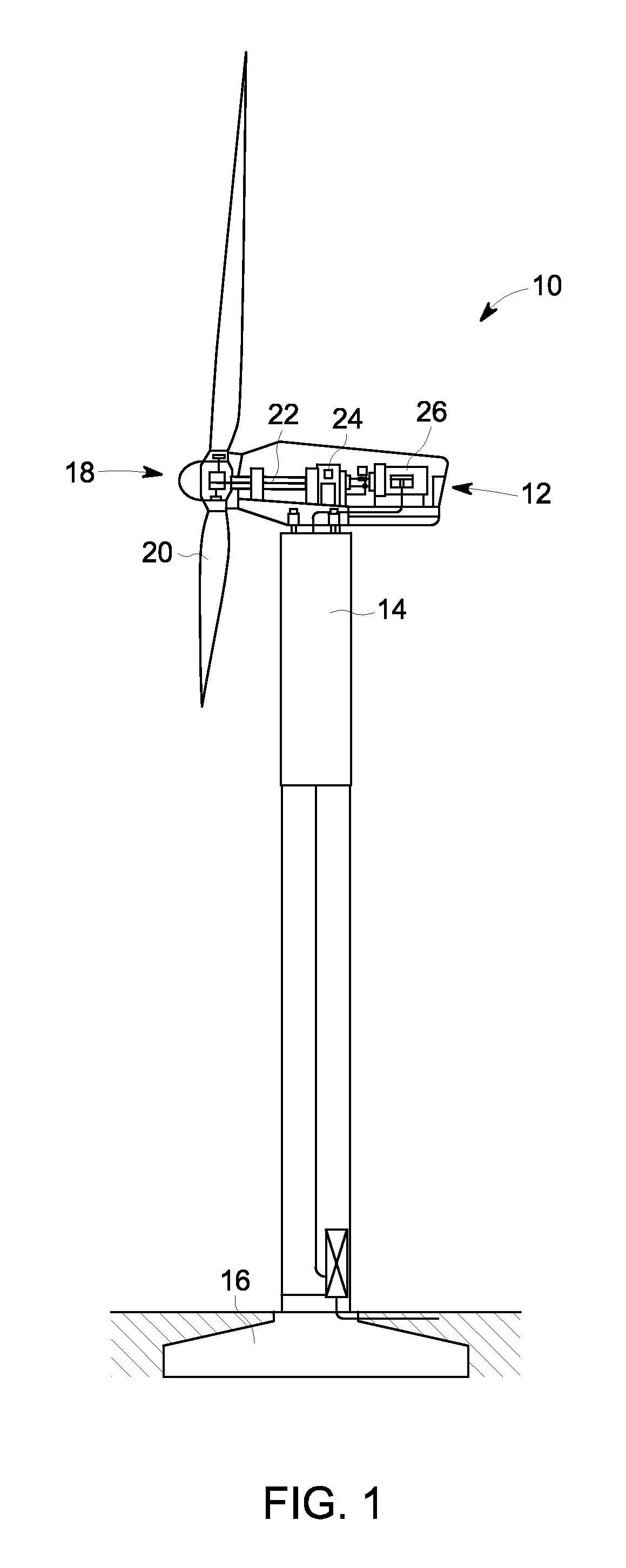

[0013]FIG. 1 depicts a wind turbine 10 including a nacelle 12 mounted on the upper end of a tower 14. The tower 14 is anchored to the ground via foundations 16. A rotor 18 having blades 20 is mounted on one end of the nacelle 12. A rotor shaft 22 couples the rotor 18 to a gearbox 24, which is in turn coupled to a generator (or alternator) 26.

[0014]The gearbox 24, shown in FIG. 2, houses a multi-stage planetary gearset 28 of a known type (shown schematically). The gearset 28 is coupled to the rotor shaft 22 by an input shaft 30 located at an “upwind” end, and is coupled to the generator 26 by a pinion shaft 32 at a “downwind” end. In operation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com