Barrel apparatus for barrel plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

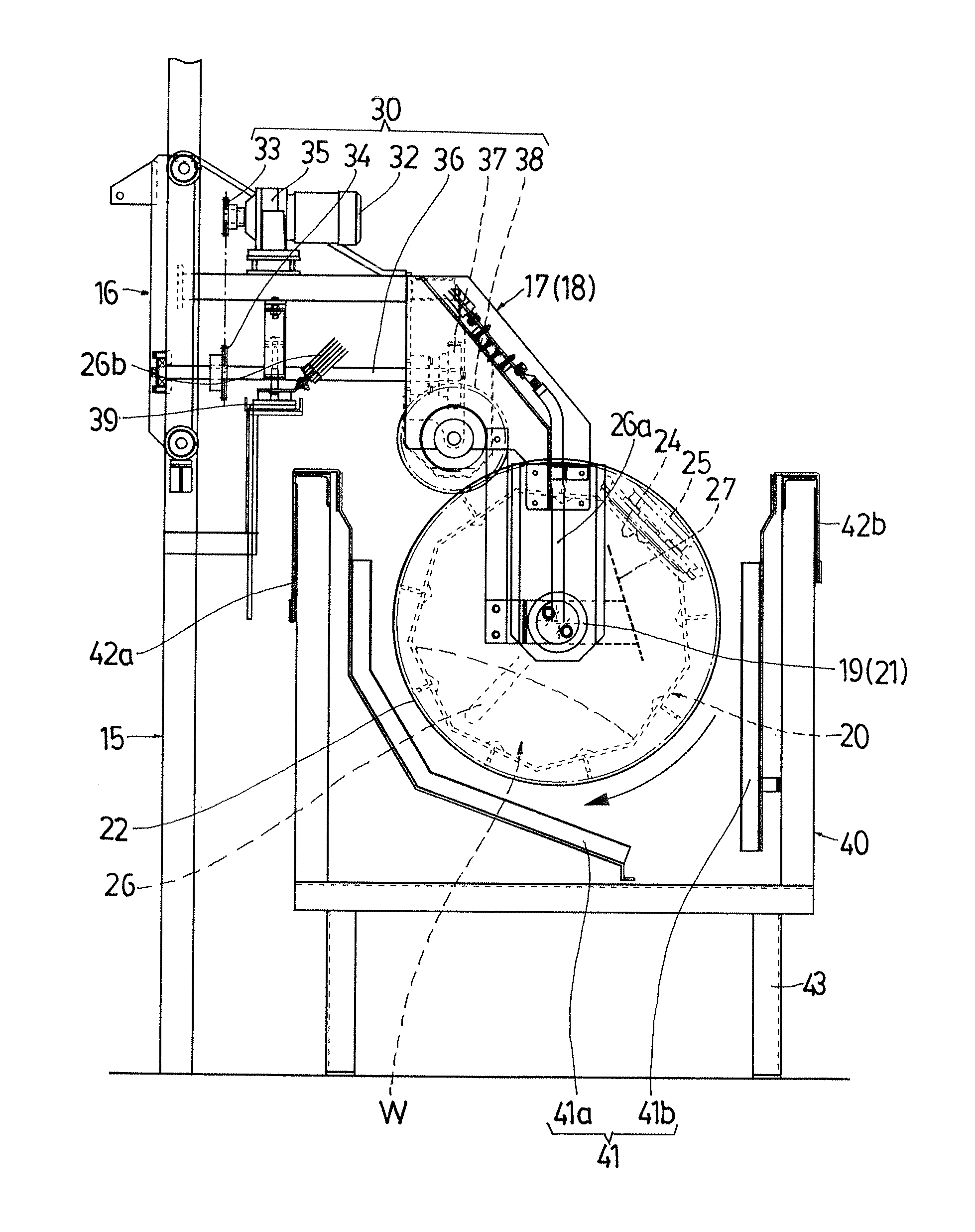

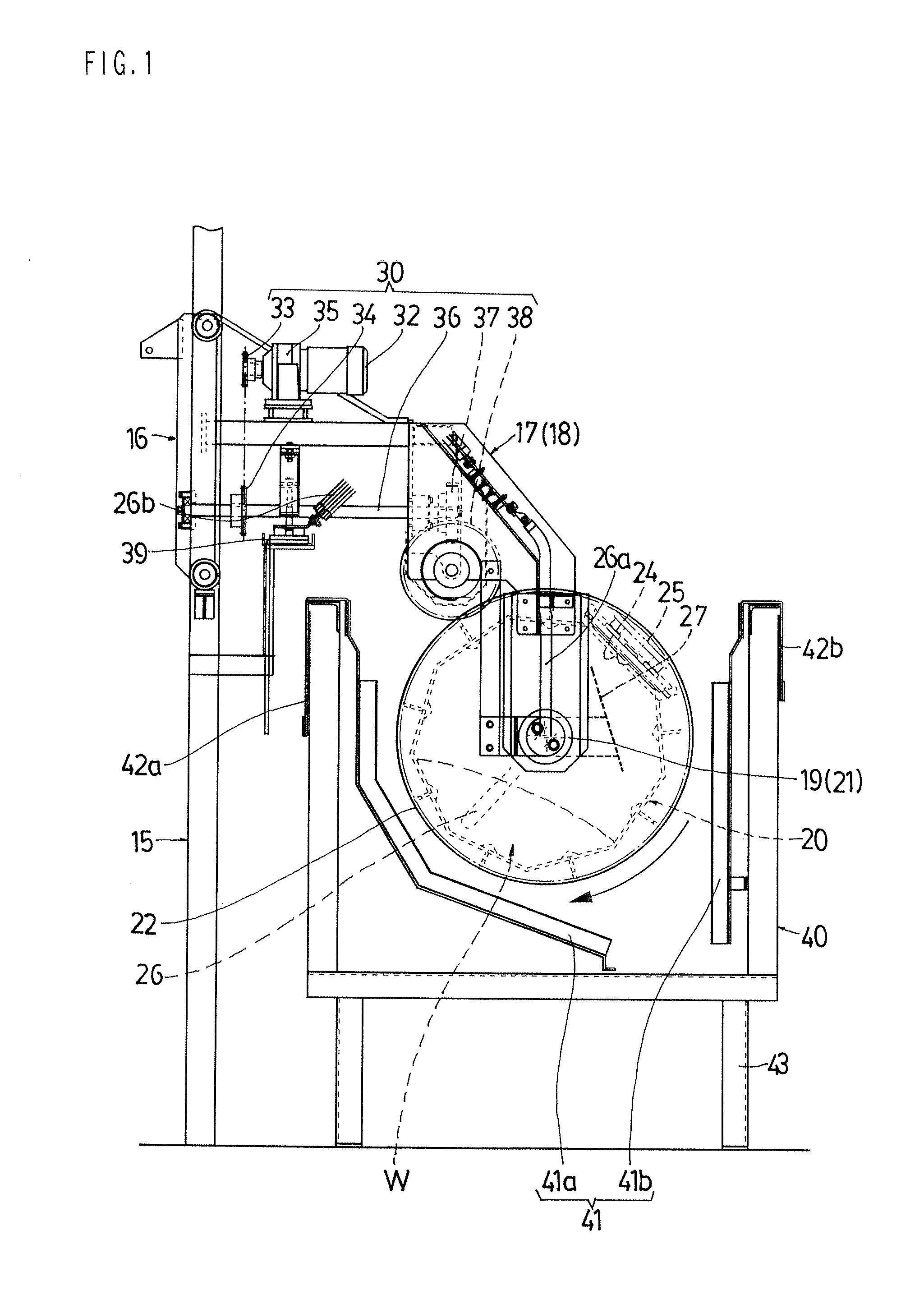

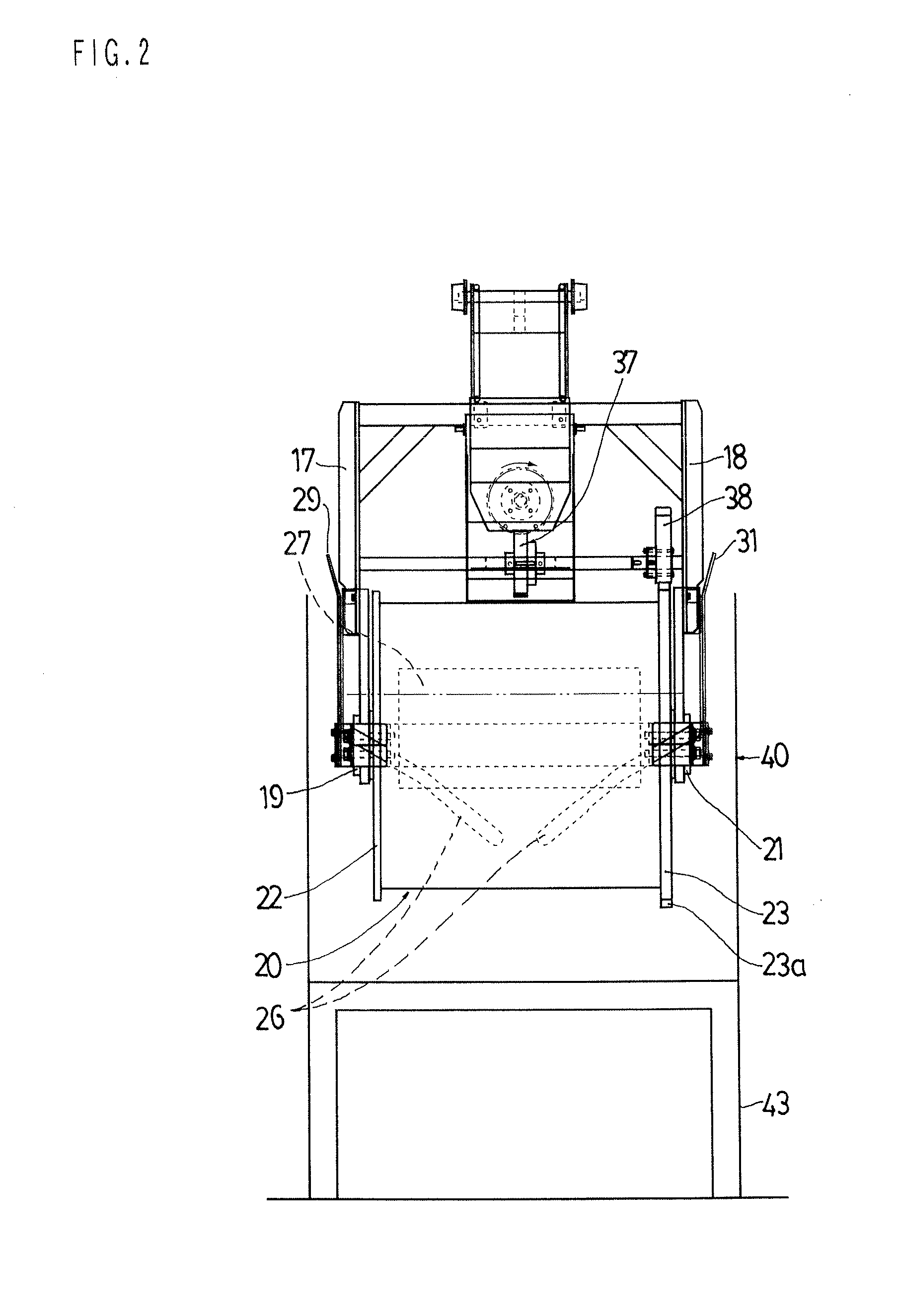

[0028]Hereinafter, embodiments of the invention will be described in detail with reference to the drawings. FIG. 1 is a front view illustrating a barrel apparatus for barrel plating of an embodiment according to the invention. In each of drawings, 15 is a supporting column of the barrel plating apparatus, 16 is an elevator. The elevator 16 is provided capable of being elevated using the supporting column 15 as a guide rail and arranged to travel in an elevator type line in a direction parallel to the paper surface in FIGS. 1. 17 and 18 are hanger arms that are configured of a pair of members in right and left, and attached to the elevator 16 at a base end section. Bearing sections 19 and 21 for a rotation shaft of the barrel are provided at the front end section thereof respectively. A barrel main body 20 of the barrel apparatus according to the invention is attached to portions of the bearing sections 19 and 21 of both front and rear end sections in a suspension-supporting state.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com