Energy-saving method for gas combustion and burner thereof

a technology of energy-saving method and burner, which is applied in the direction of combustion types, household stoves or ranges, gaseous heating fuels, etc., can solve the problems of unstable combustion quality, waste of precious resources, pollution of environment, etc., and achieves improved utilization ratio, reduced gas utilization ratio, and greater firepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0019]An energy-saving method for gas combustion comprises the following steps:

-1) gas enters into a hearth for one time or times of compression and expansion; -2) air is introduced into the hearth and is mixed with the gas; -3) the gas is ignited, the volume of the gas and the volume of the air are rapidly expanded and compressed in the hearth, and the bonds of gas molecules are cracked; -4) the gas rotates in the hearth at a high speed and is fully combusted in a stove body to emit heat; and -5) when the gas is combusted, the gas is preheated before entering into the hearth.

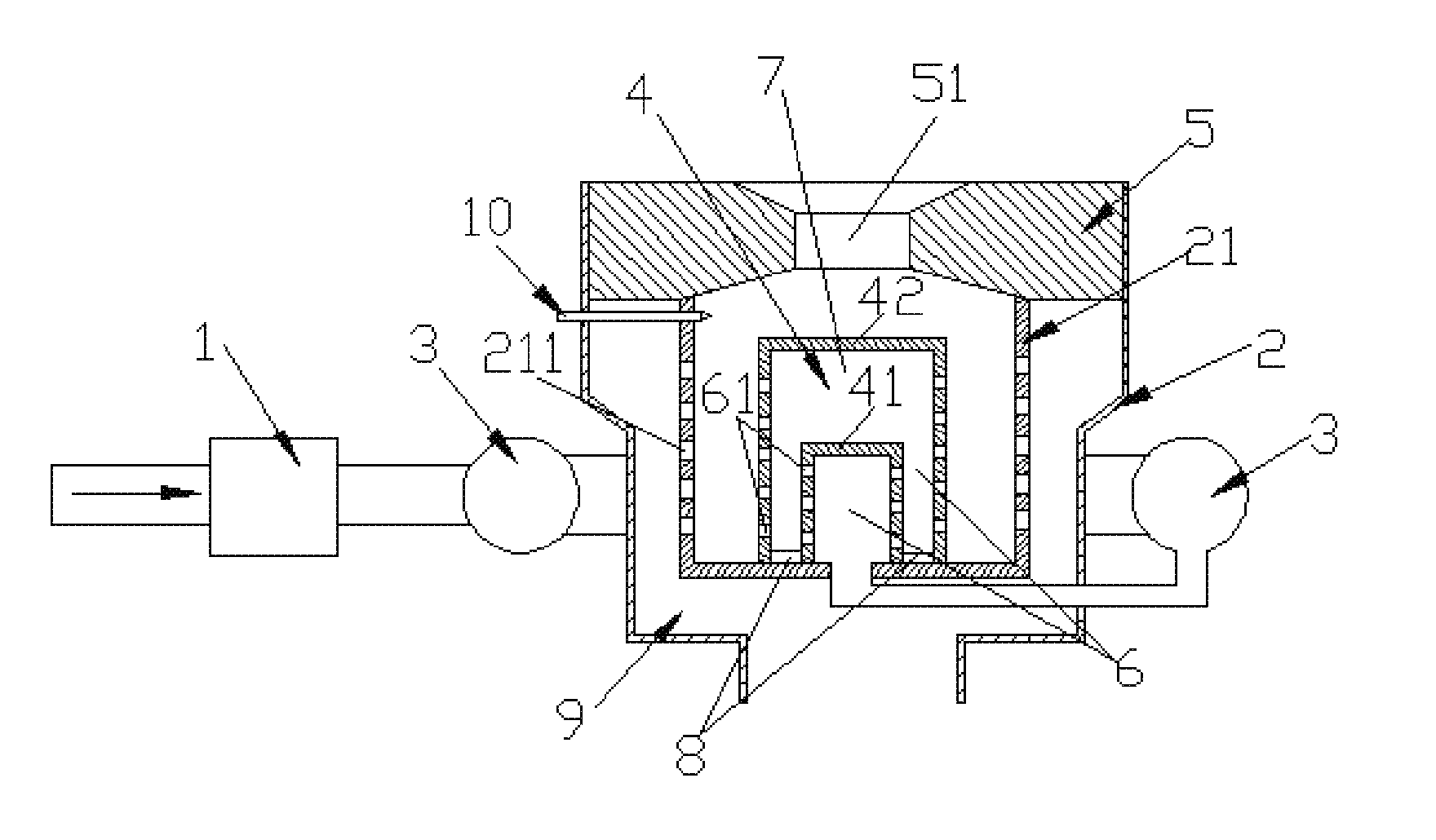

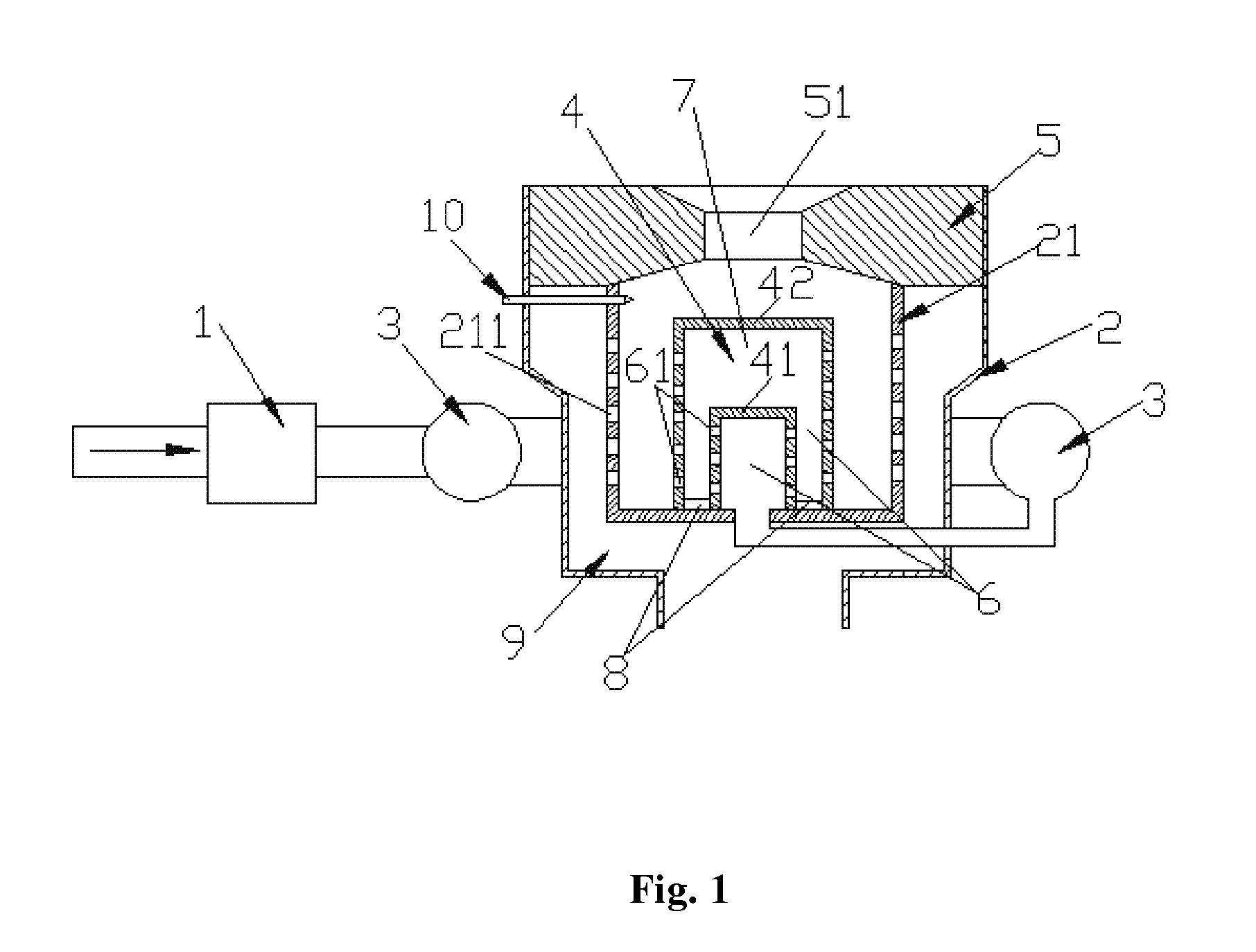

[0020]A device for implementing said energy-saving method for gas combustion is a black-hole gas burner, as shown in FIG. 1, the black-hole gas burner comprises a safety valve 1, a stove body 2 and a siphoning and preheating gas drum 3. A hearth 21 of the stove body 2 is internally provided with an expander 4 and the expander 4 is comprised of an internal expander 41 and an external expander 42. The internal / ex...

embodiment 2

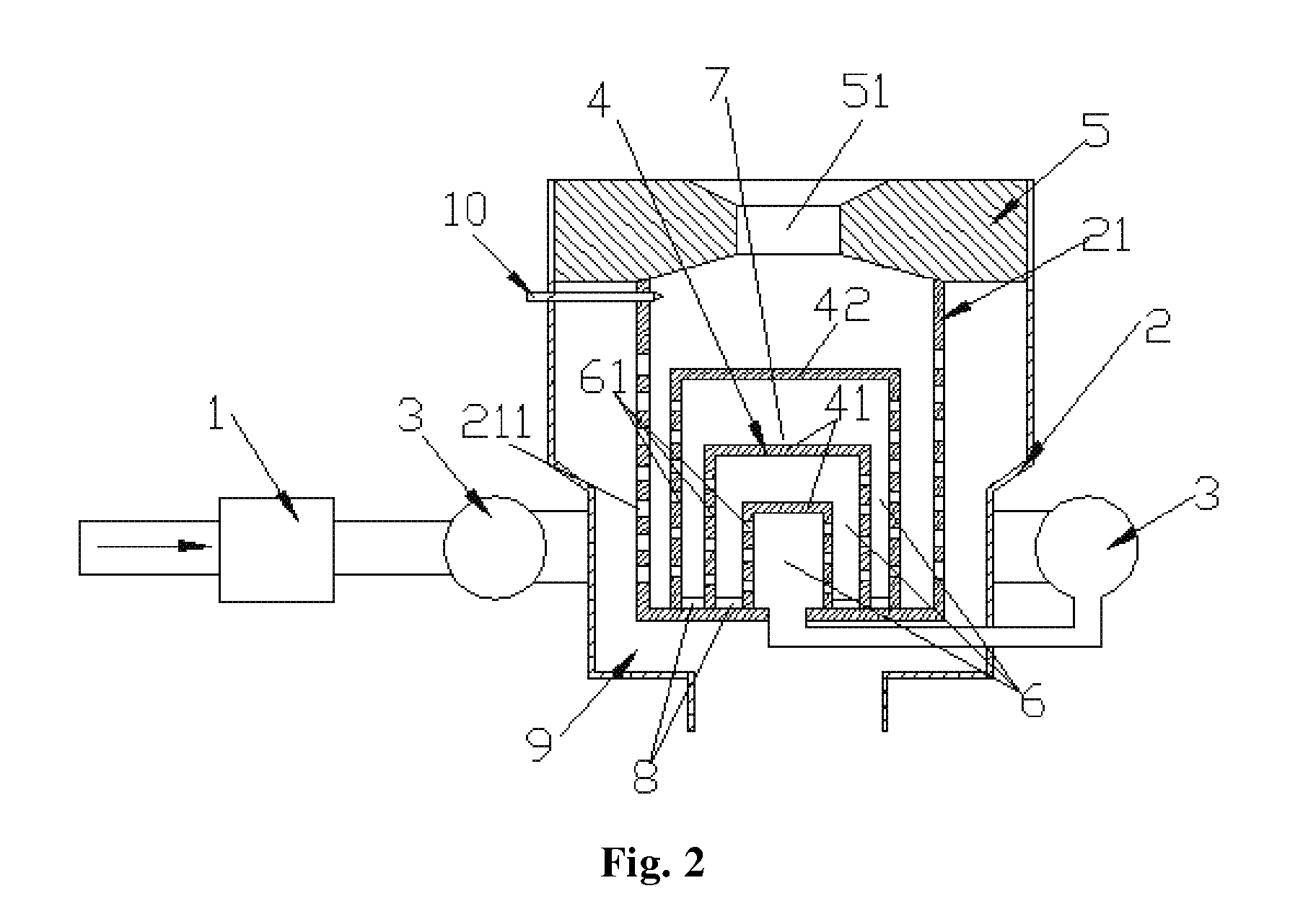

[0025]As shown in FIG. 2, the number of the internal expander 41 of the expander 4 in the black-hole gas burner of the present invention is two, and the others are the same as those in the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com