Pump controller

a technology of pump controller and controller, which is applied in the direction of process and machine control, positive displacement liquid engine, instruments, etc., can solve the problems of arcing and scorching between the contacts of the switch, and the mechanical switch has several limitations, so as to reduce the dependency. only

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

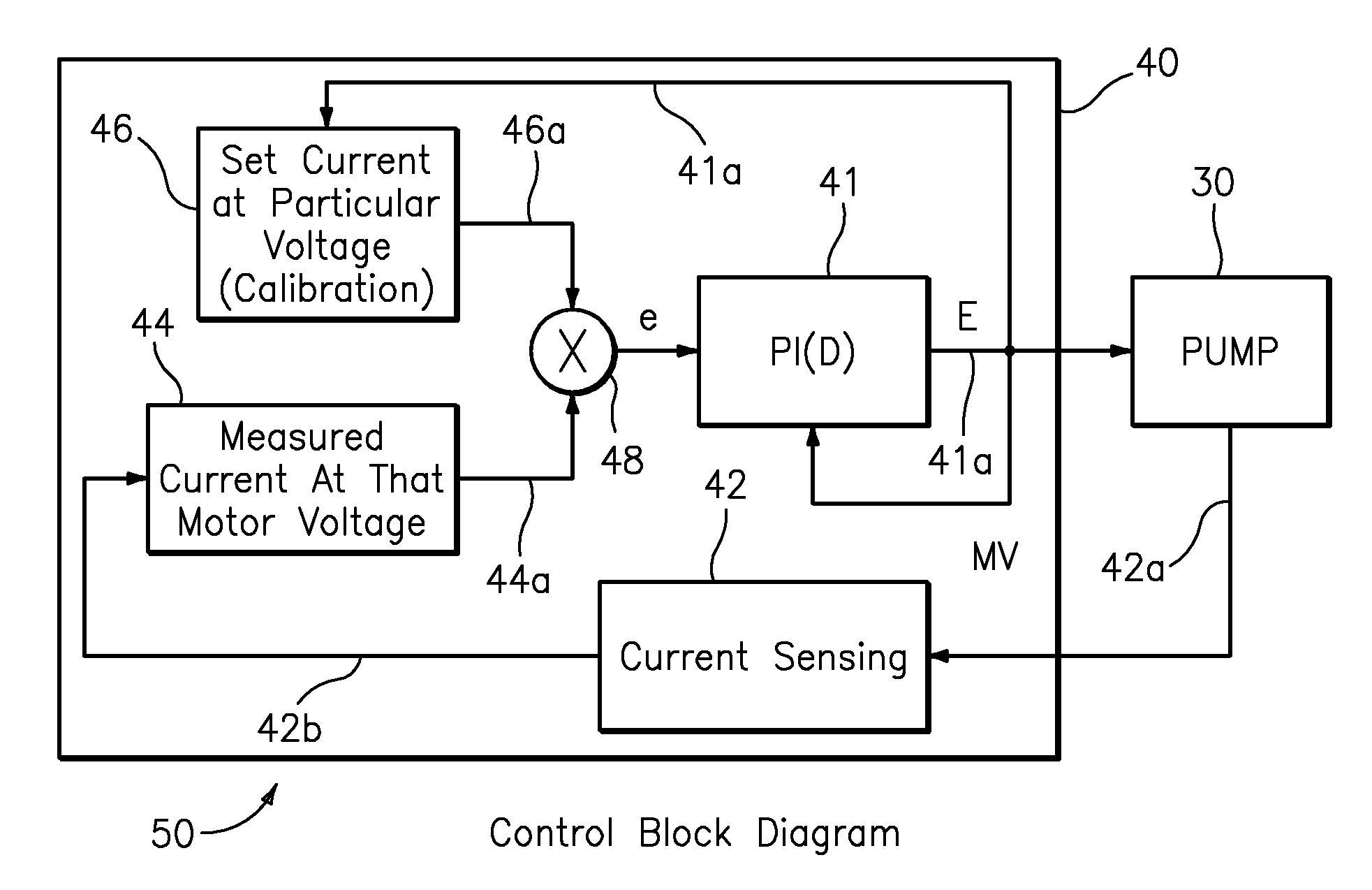

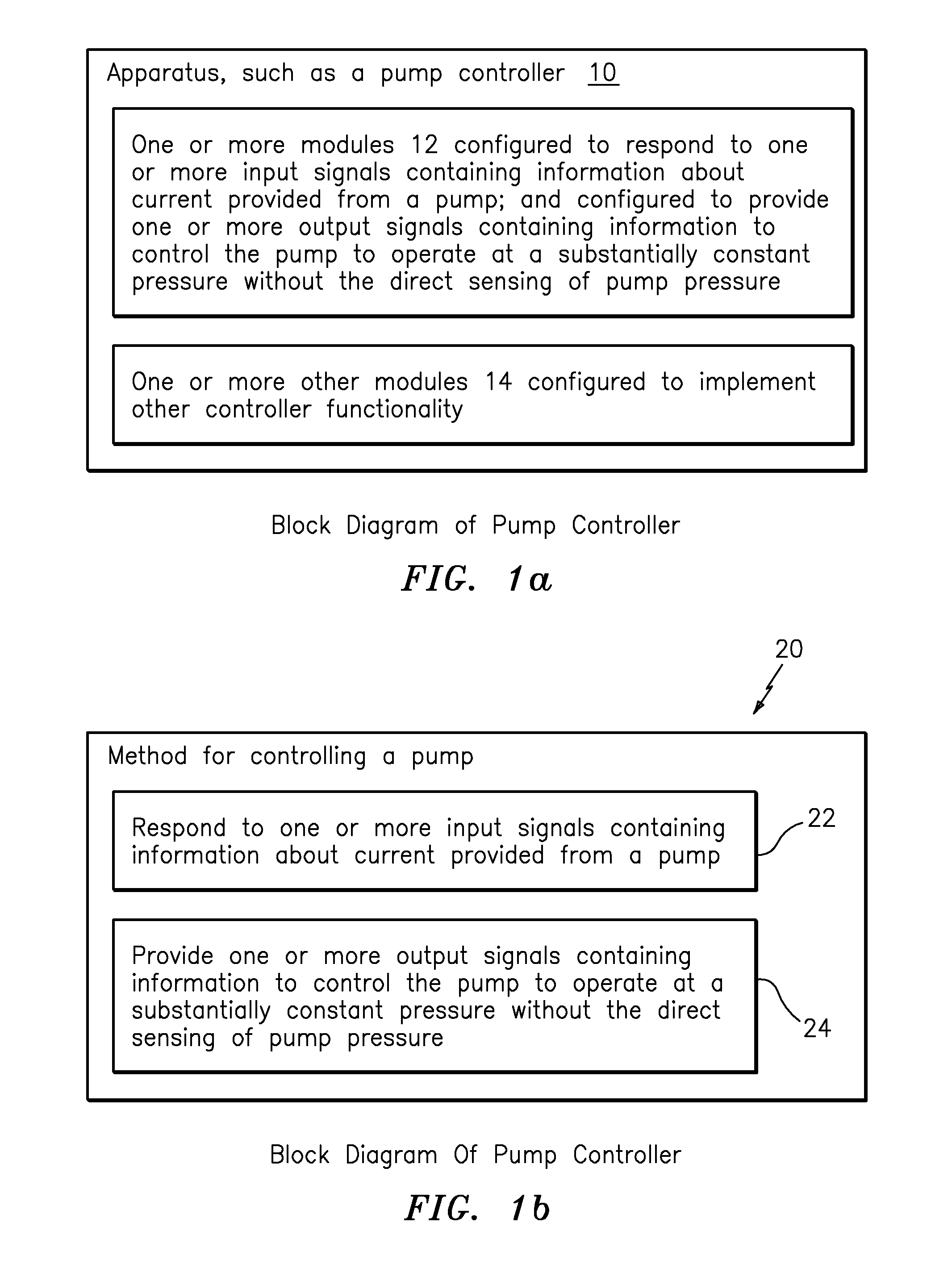

[0026]FIGS. 1a shows apparatus in the form of a pump controller generally indicated as 10 featuring one or more modules 12 and 14. The one or more modules 12 is configured to respond to one or more input signals containing information about current provided from a pump (see element 30 (FIG. 4); and also configured to provide one or more output signals containing information to control the pump 30 (FIG. 4) to operate at a substantially constant pressure without the direct sensing of pump pressure.

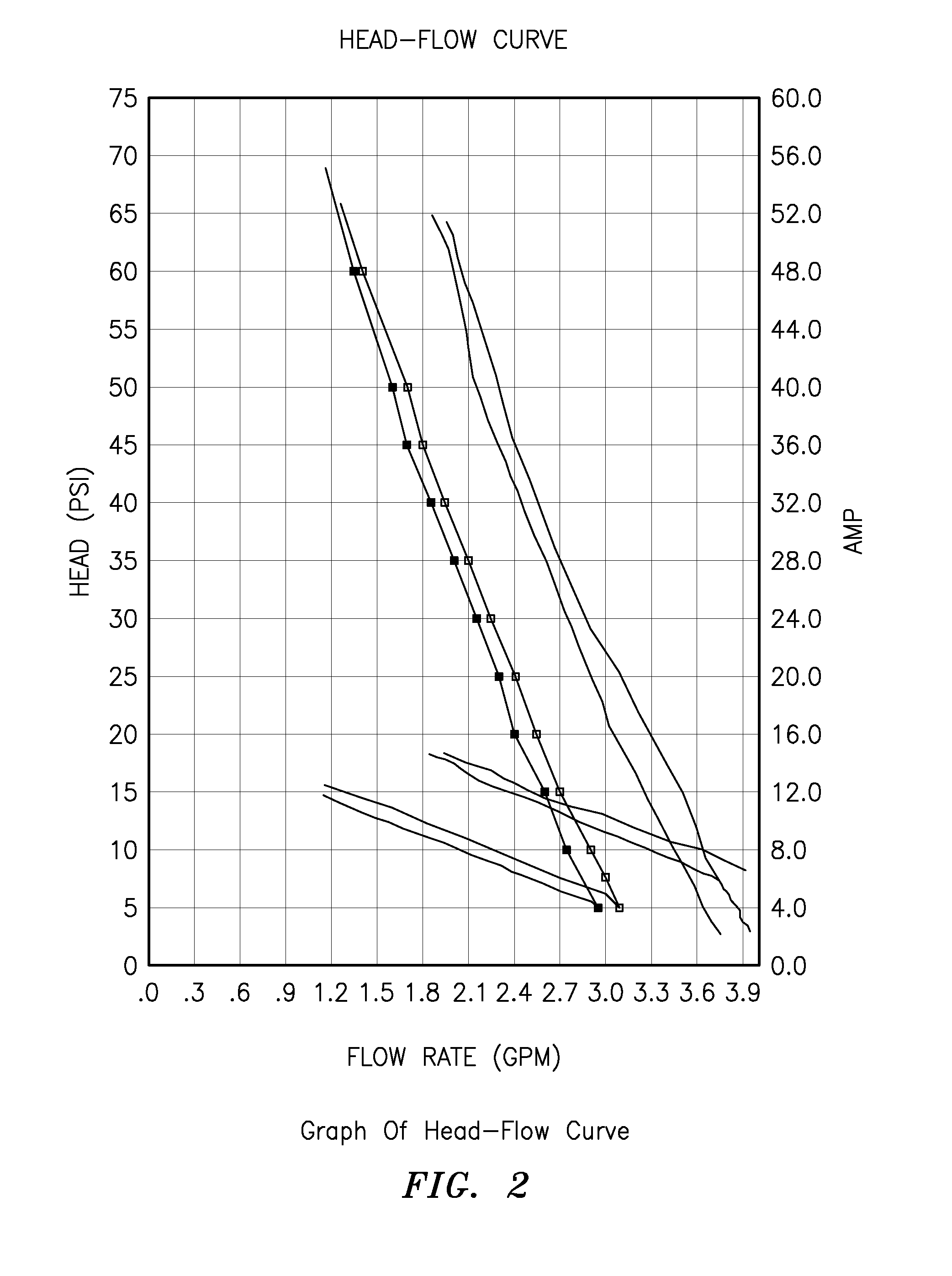

[0027]According to some embodiments of the present invention, the one or more modules 12 may be configured to control the operation of the pump 30 (FIG. 4) based at least partly on a table of characteristics related to voltage and current that is calibrated for each pump, where the characteristics may be determined with the following equation:

I=Vm+C,

where

m=(I1−I2) / (V1−V2),

C=(V1*I2−V2*I1) / (V1−V2),[0028](V1, I1): Low point of curve, and[0029](V2, I2): High point of curve.

The one or more input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com