Highly flexible absorbent laminate and method for the production thereof

a technology of absorbent laminate and absorbent layer, which is applied in the direction of chemistry apparatus and processes, transportation and packaging, bandages, etc., can solve the problem of limited integrity of the lamina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

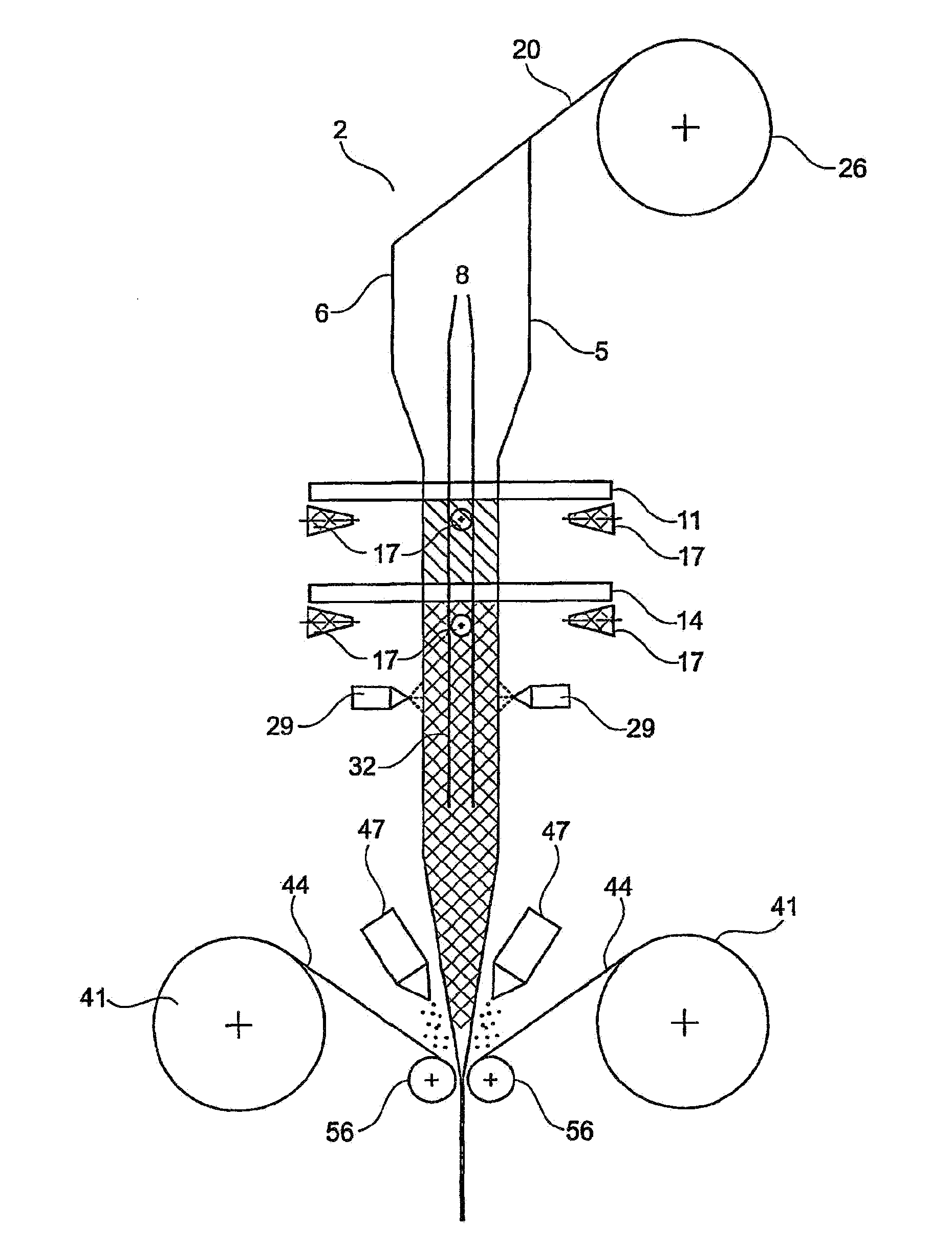

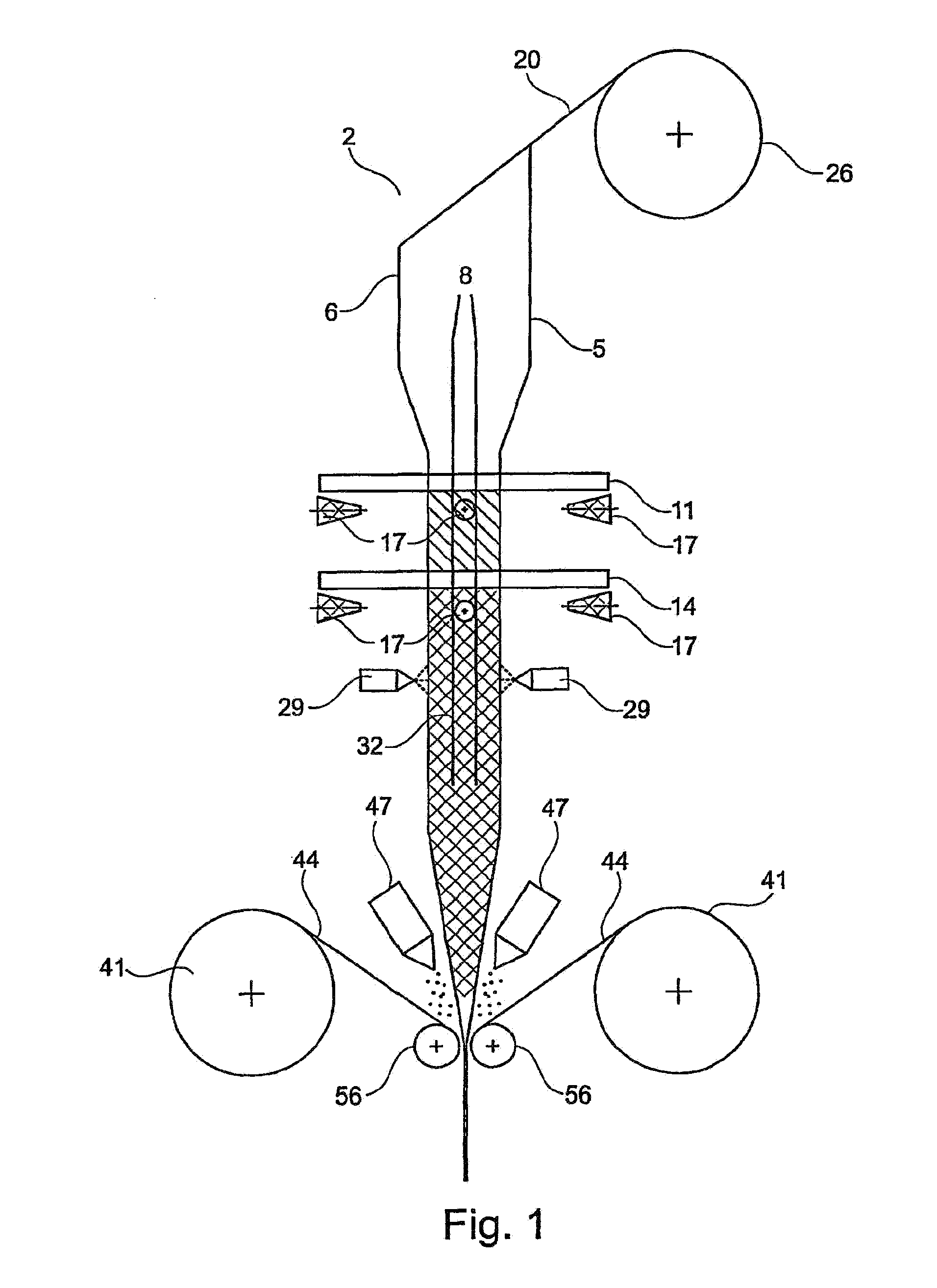

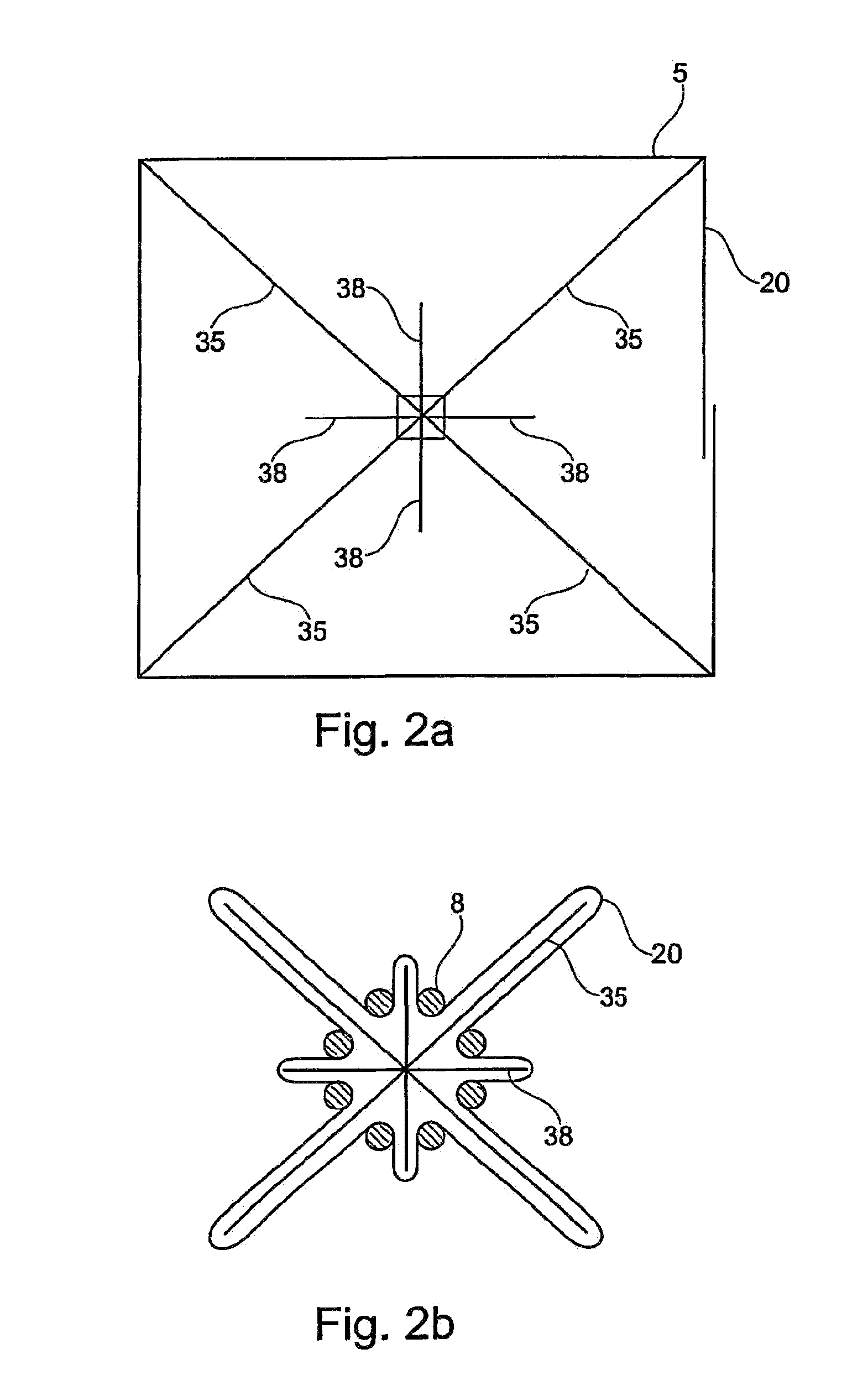

[0012]Superabsorbents undergo a weight increase of 2500-5000% as they imbibe liquid. The associated increase in volume has to be accommodated through suitable flexibility on the part of the surrounding carrier material. This is in principle not a problem in the case of conventional pulp / superabsorbent pads, since the pulp allows expansion in all three dimensions. In the case of so-called superabsorbent laminates, in which superabsorbent granules or superabsorbent / fiber mixtures are fixed using pressure-sensitive adhesive or thermally between two or more plies of nonwovens, film, tissue or the like, this function has to be made possible by the outer plies of the laminate, whether through stretching or through geometric flexibility. But at all times the containment of the superabsorbent has to be ensured without one of the outer plies breaking or the lamination tearing open. It is further desirable that this laminate be elastically extendable not just perpendicularly to its production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| water vapor permeable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com