Thermal Metal Growler

a metal growler and metal technology, applied in the direction of drinking vessels, transportation and packaging, mechanical equipment, etc., can solve the problems of inability to manage a 5 or more gallon keg purchase to enjoy craft beers in their home, limited bottling or no bottling in breweries, and inability to maintain kegged beer for personal consumption,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

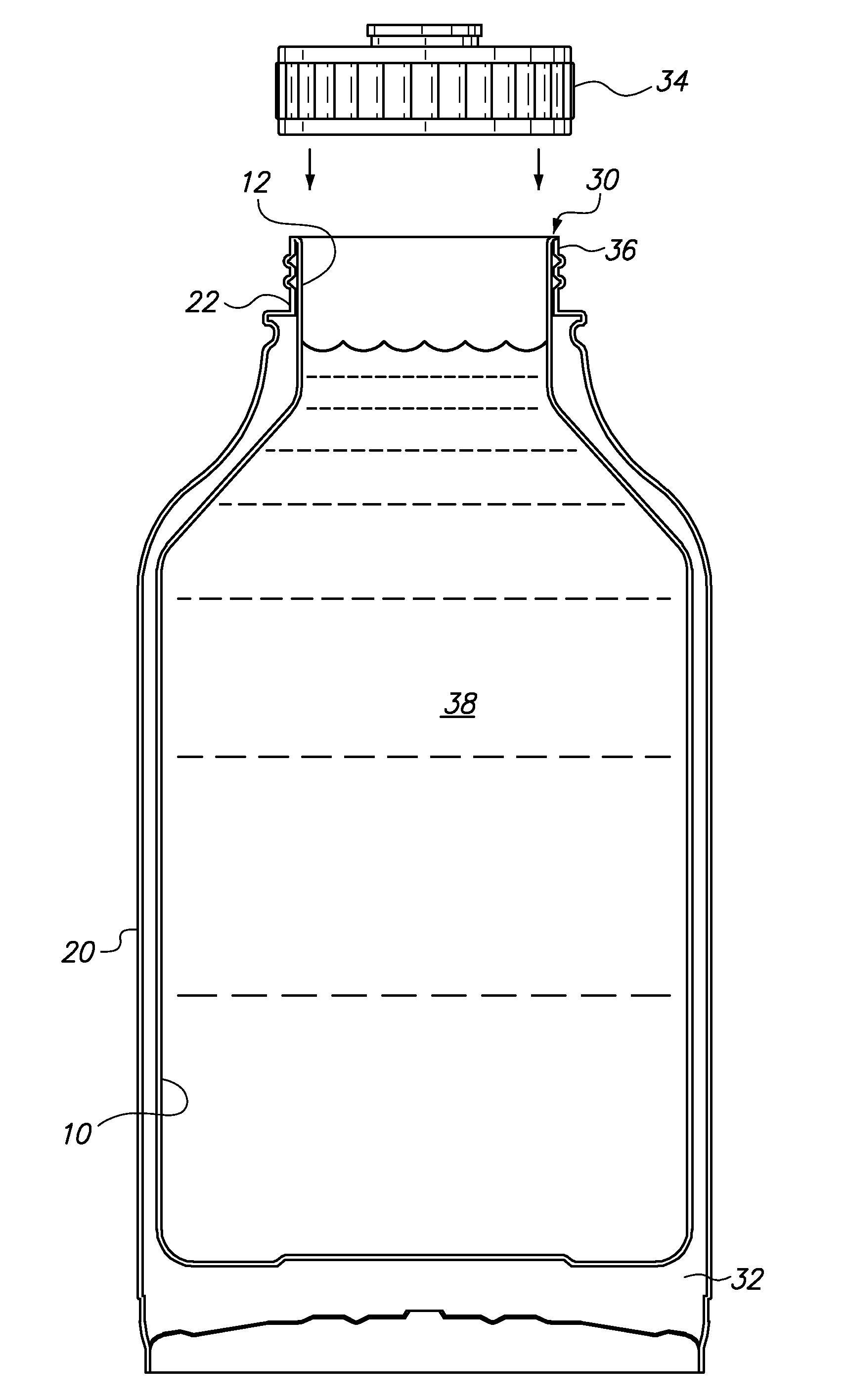

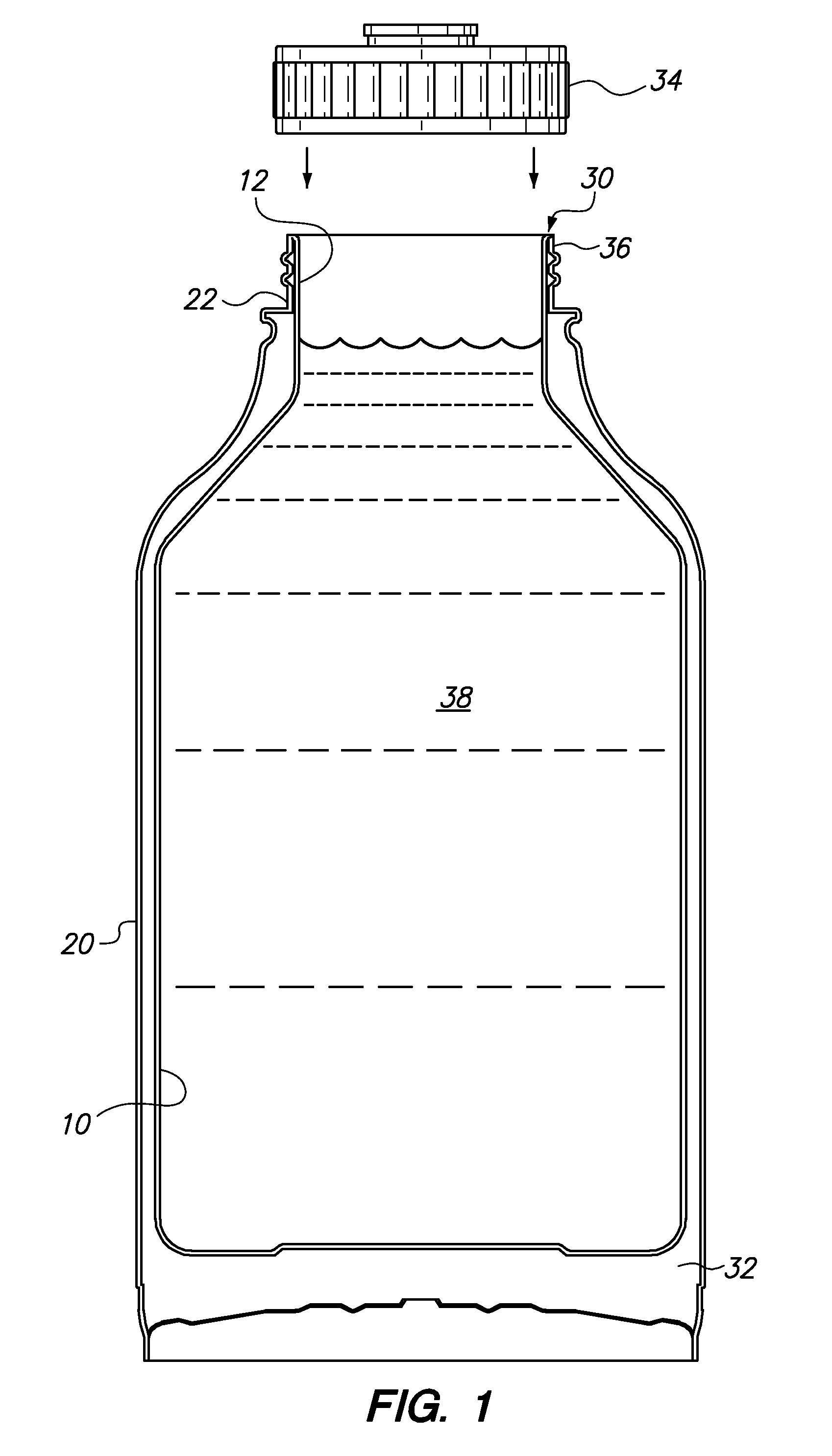

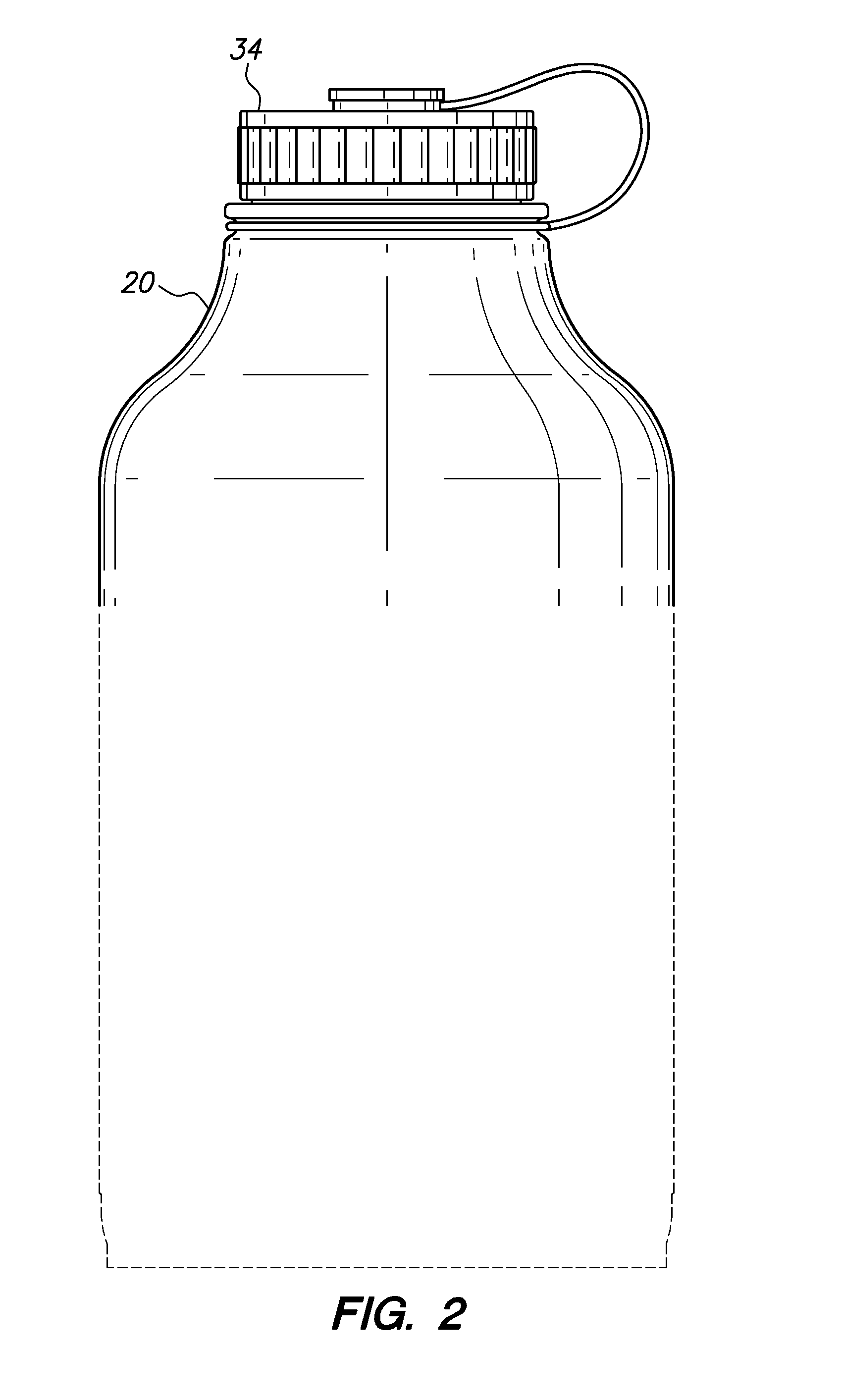

[0024]FIG. 1 shows the preferred embodiment of the present invention in cutaway. Depicted is the inner bottle 10, which has a neck portion 12, the outer bottle 20 with an outer bottle neck portion 22. The inner bottle neck portion 12 and the outer bottle neck portion 22, connected together at a point 30 to minimize conductivity between the inner 10 and outer bottles 20 and being sealed so as to permit a vacuum between the two bottles 32.

[0025]A means for resealably closing the inner bottle is provided, with the preferred method being the placement of external threads 36 around the perimeter of the outer bottle neck 22, and fitting to those threads 36 a sealing threaded cap 34. While this is the preferred embodiment, providing a high degree of utility and economy, other methods may similarly be used, including snap caps, flip caps and other means of allowing the bottle to be filled and sealed to preserve the carbonation of the inner bottle.

[0026]Contained within the bottle is a carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com