Chimney

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

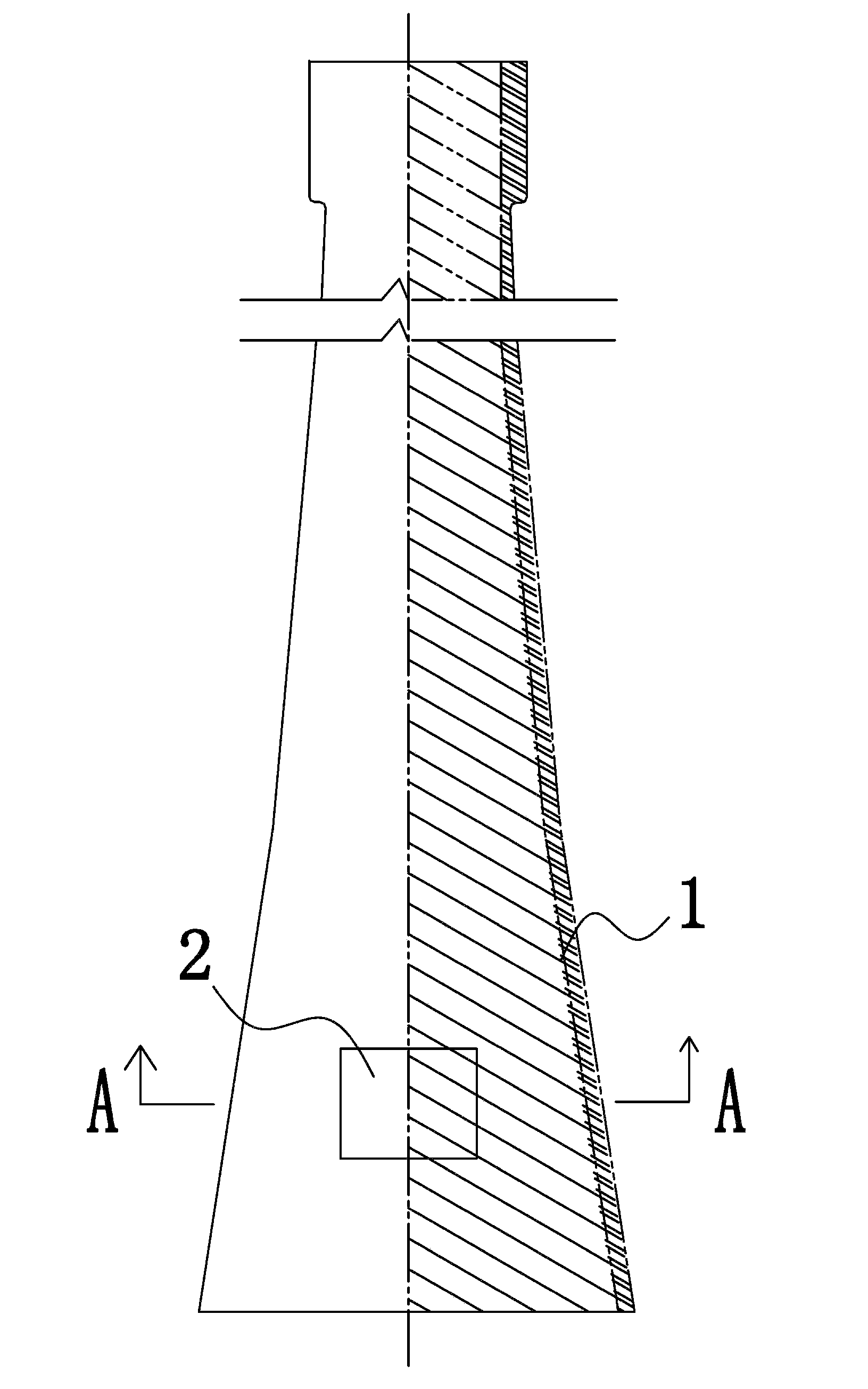

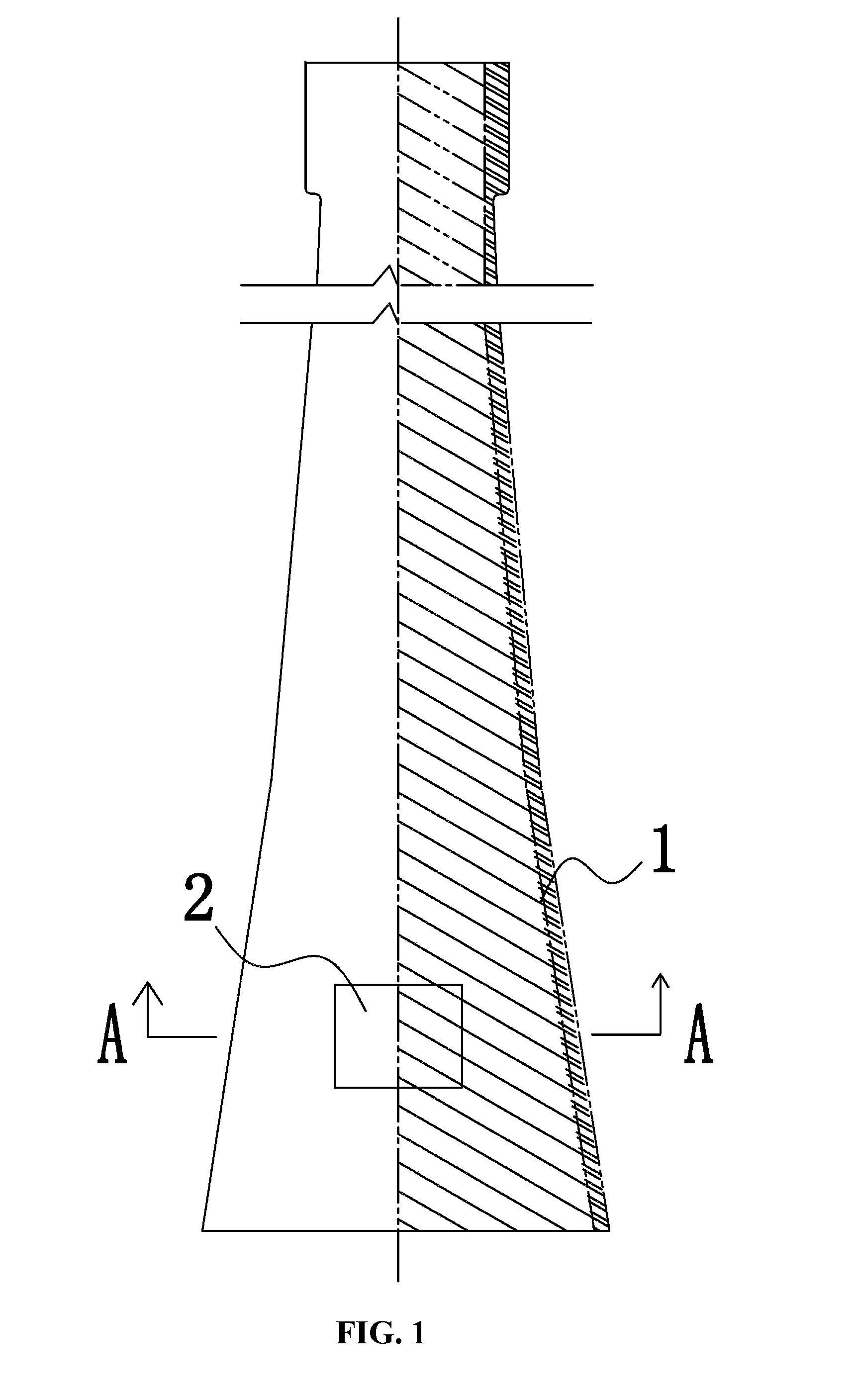

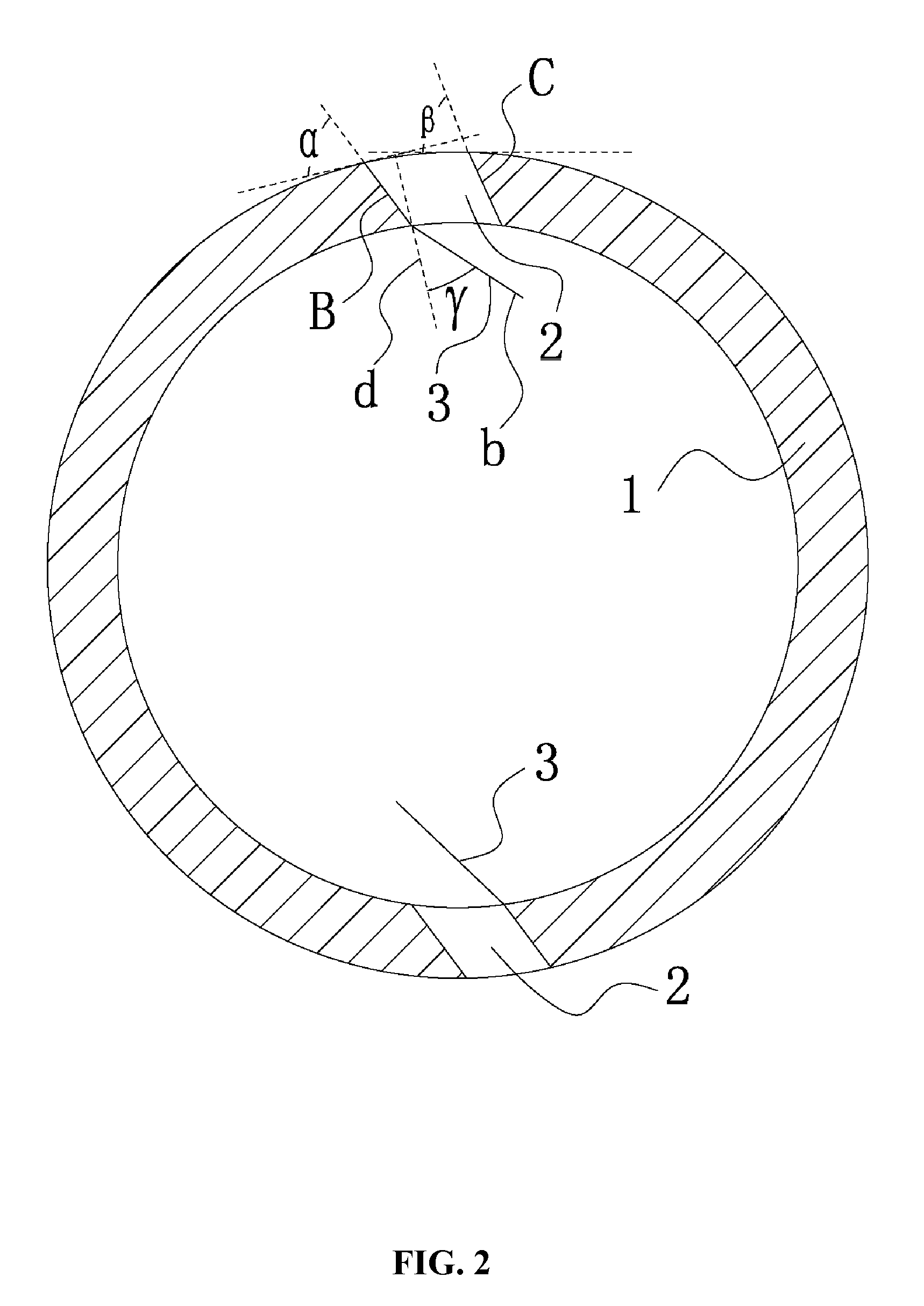

[0026]A chimney, as shown in FIGS. 1-2, comprises: a chimney cylinder 1, and a smoke inlet 2 arranged on a lower part of the chimney cylinder 1. The smoke inlet 2 comprises a first side wall B and a second side wall C on a cross-section of the chimney cylinder 1. A baffle 3 has two ends, one end is disposed on a junction of the first side wall B of the smoke inlet 2 and an inner wall of the chimney cylinder 1, and the other end extends inside and close to a center of the chimney cylinder. The baffle 3 is a straight plate. An angle γ is formed between the baffle 3 and a perpendicular line d of a tangent at a position where the baffle 3 is disposed, and the angle γ is 35°. An angle α is formed between the first side wall B and a first tangent at an intersection of the first side wall B and an outer wall of the chimney cylinder 1, and the angle α is 45°. An angle β is formed between the second side wall C and a second tangent at an intersection of the second side wall C and the outer w...

example 2

[0029]A chimney, as shown in FIGS. 1-4, comprises: a chimney cylinder 1, and a smoke inlet 2 arranged on a lower part of the chimney cylinder 1. The smoke inlet 2 comprises a first side wall B and a second side wall C on a cross-section of the chimney cylinder 1. An angle α is formed between the first side wall B and a first tangent at an intersection of the first side wall B and an outer wall of the chimney cylinder 1, and the angle α is 60°. An angle β is formed between the second side wall C and a second tangent at an intersection of the second side wall C and the outer wall of the chimney cylinder 1, and the angle β is 45°.

[0030]Like Example 1, a baffle 3 has two ends, one end is disposed on a junction of the first side wall B of the smoke inlet 2 and an inner wall of the chimney cylinder 1, and the other end extends inside and close to a center of the chimney cylinder. The baffle is a folded plate shown in FIG. 5, an arc plate shown in FIG. 6, or a curved plate shown in FIG. 7....

example 3

[0032]A chimney, as shown in FIGS. 1 and 8, comprises: a chimney cylinder 1, and a smoke inlet 2 arranged on a lower part of the chimney cylinder 1. The smoke inlet 2 comprises a first side wall B and a second side wall C on a cross-section of the chimney cylinder 1. A baffle 3 has two ends, one end is disposed on a junction of the first side wall B of the smoke inlet 2 and an outer wall of the chimney cylinder 1, and the other end extends inside the chimney cylinder. The baffle 3 is a curved plate. Also, the baffle 3 can be other shapes, and the baffle can be arranged on an outer wall of the chimney cylinder 1, or on the second side wall C of the smoke inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com