Variable displacement hydraulic pump/motor with hydrostatic valve plate

a hydraulic pump/motor and valve plate technology, applied in the direction of positive displacement engines, reciprocating piston engines, liquid engines, etc., can solve the problems of large size, more complex design of valve plate, and generally limited maximum total displacement angles of valve plate designs, so as to facilitate the creation of hydrostatic pads, reduce potential wear, and eliminate negative traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

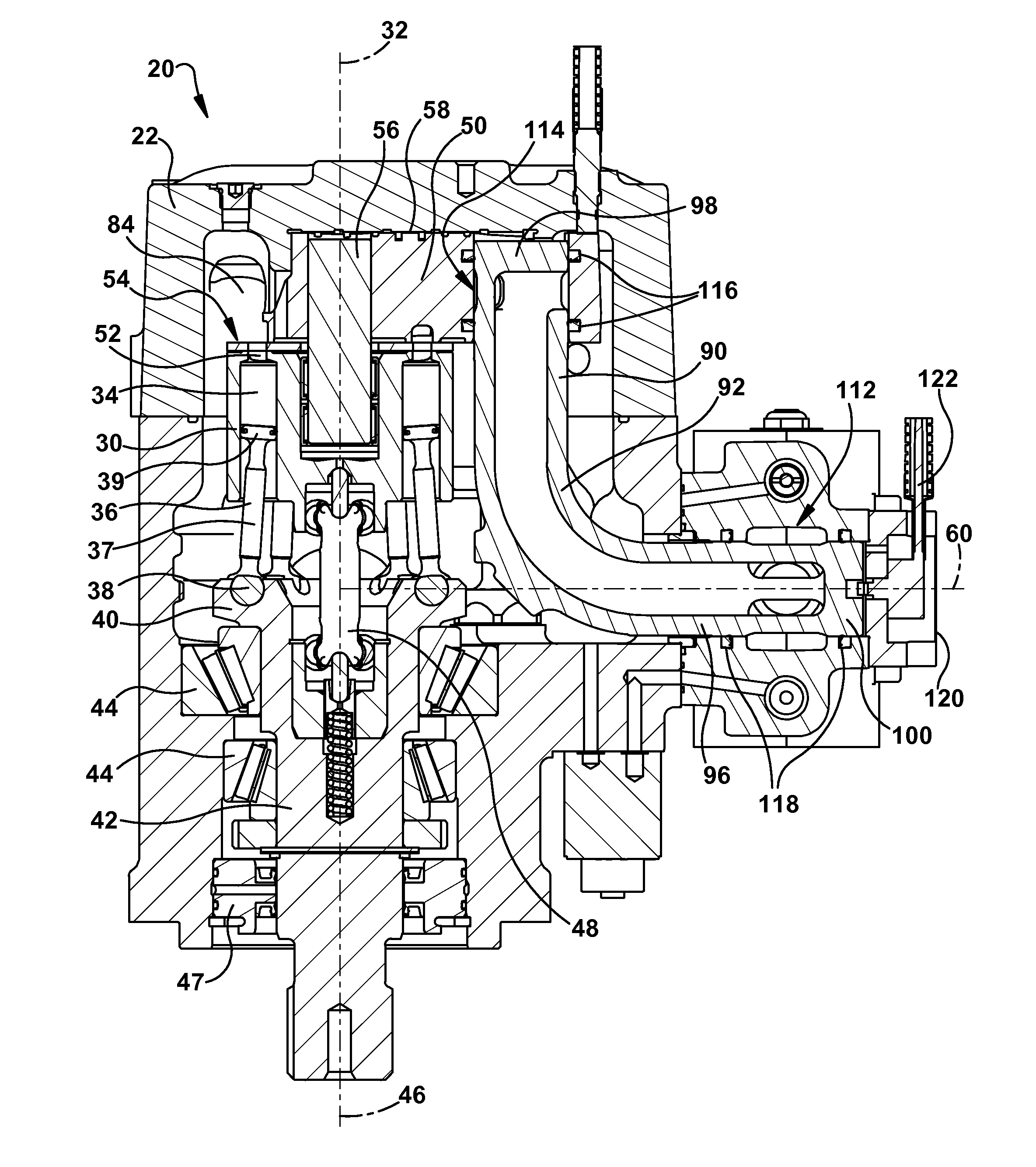

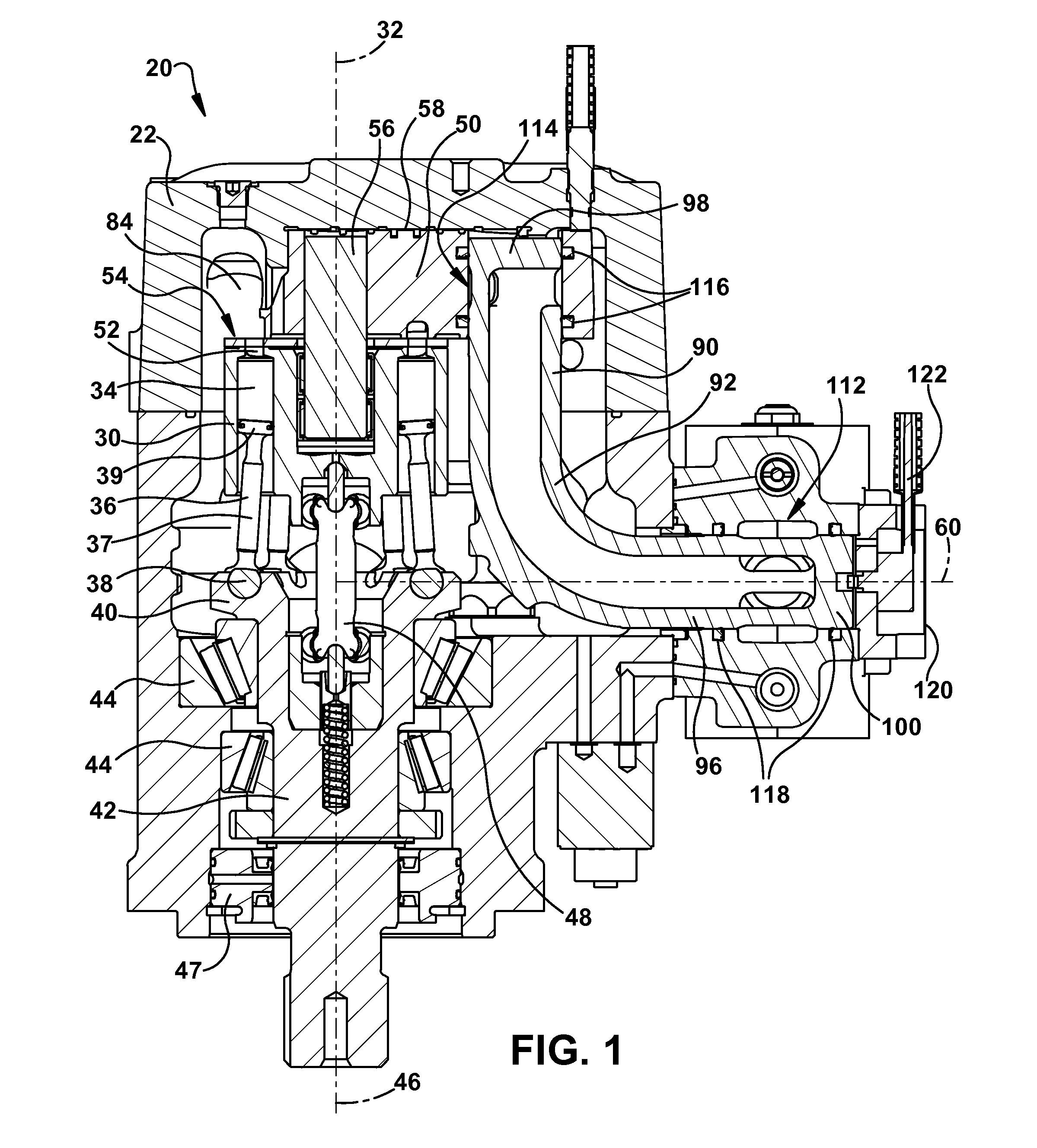

[0033]The present invention provides an improved design for a hydrostatic axial piston machine, such as a hydraulic pump or a hydraulic motor, or a machine that can operate as either a pump or a motor. This design is particularly applicable to a variable displacement axial piston machine.

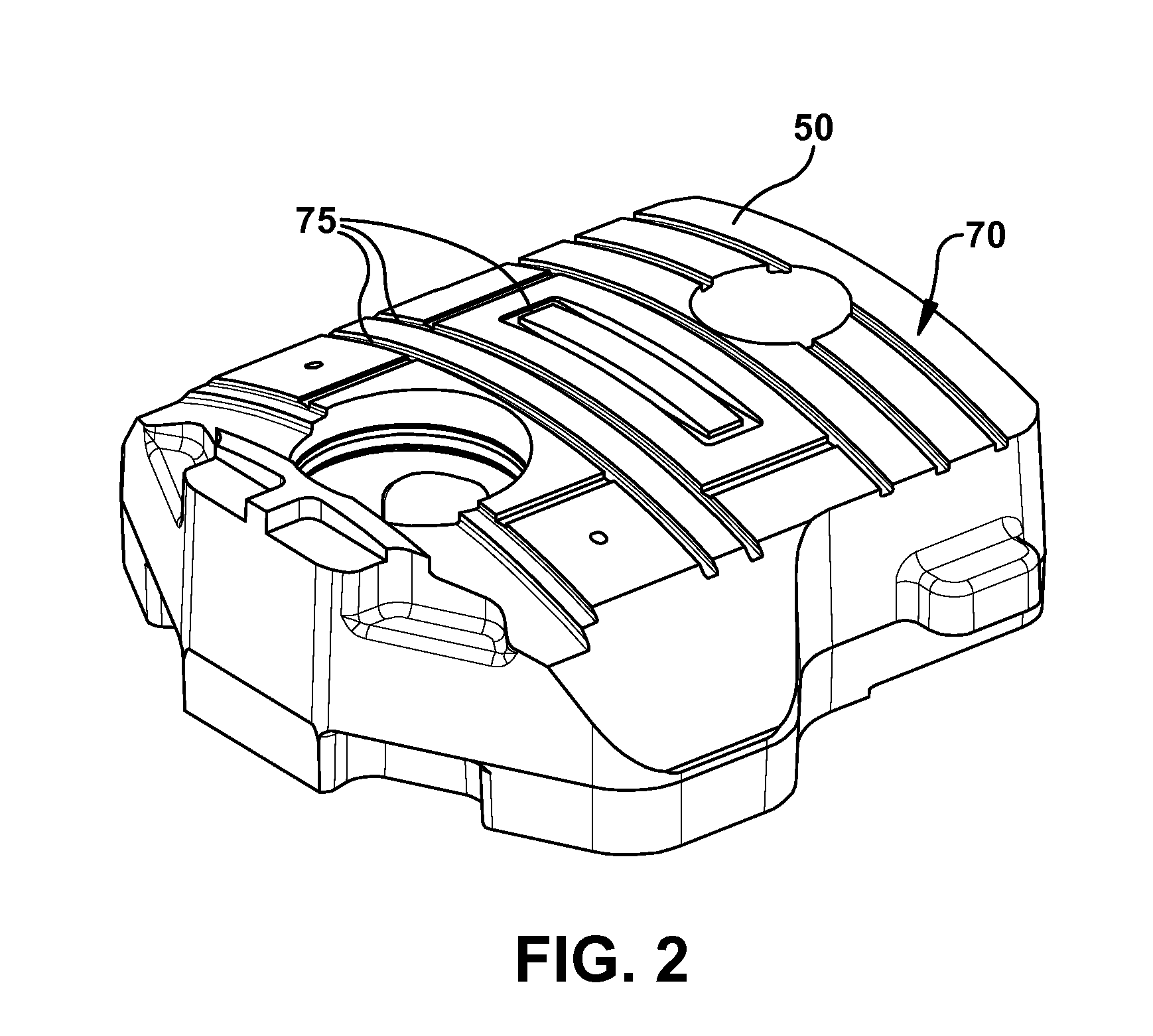

[0034]The axial piston machine provided by the invention provides several advantages over prior axial piston machines. For example, the machine includes a valve plate that has a hydrostatic bearing surface facing the machine casing to reduce potential wear and to reduce sliding friction; the valve plate has an easily-machined flat running surface; and the valve plate integrates hydrostatic valve plate support and valve plate timing into the flat running surface of the valve plate.

[0035]Additionally, the hydrostatic piston machine includes a flow tube separate from the valve plate. As described in additional detail below, the flow tube and the valve plate are not fixed relative to one another so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com