Dental veneers and methods of manufacture

a technology of dental veneers and manufacturing methods, applied in the field of dental veneers, can solve the problems of needing laboratory work with a considerable expense of time and money, and producing new dental veneers, and achieve the effect of reducing the amount of natural dental tissu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

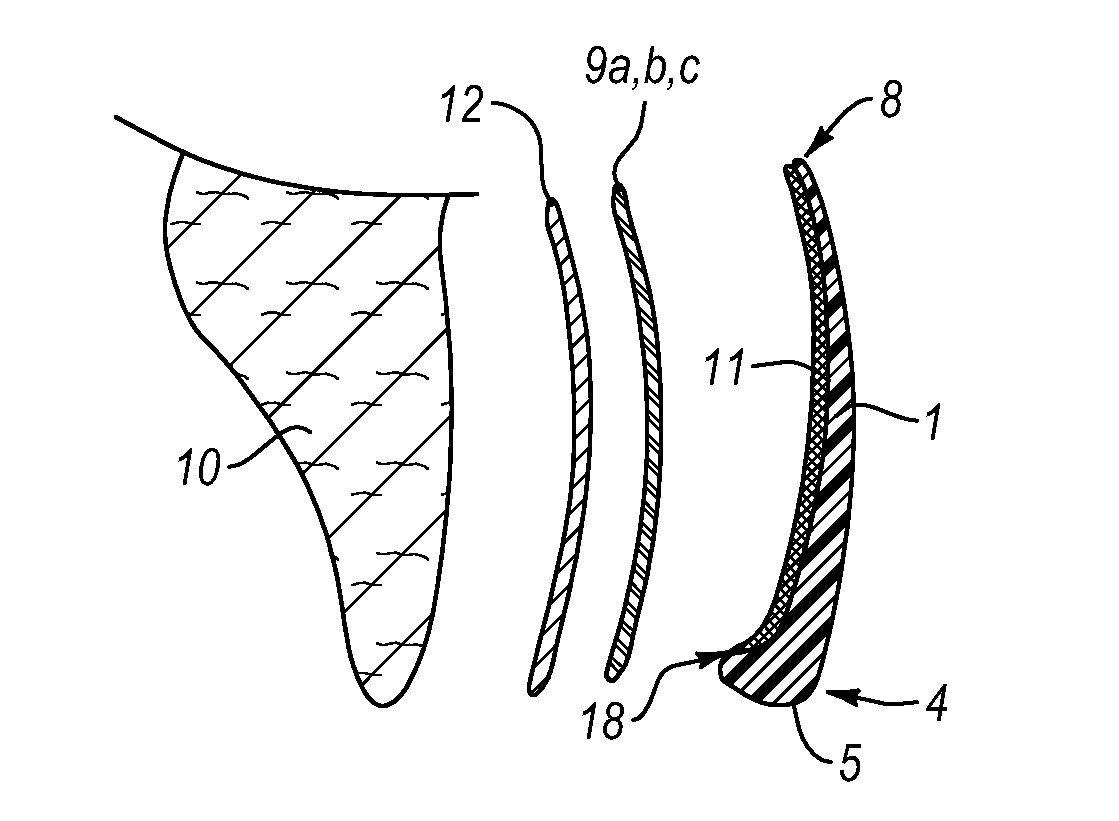

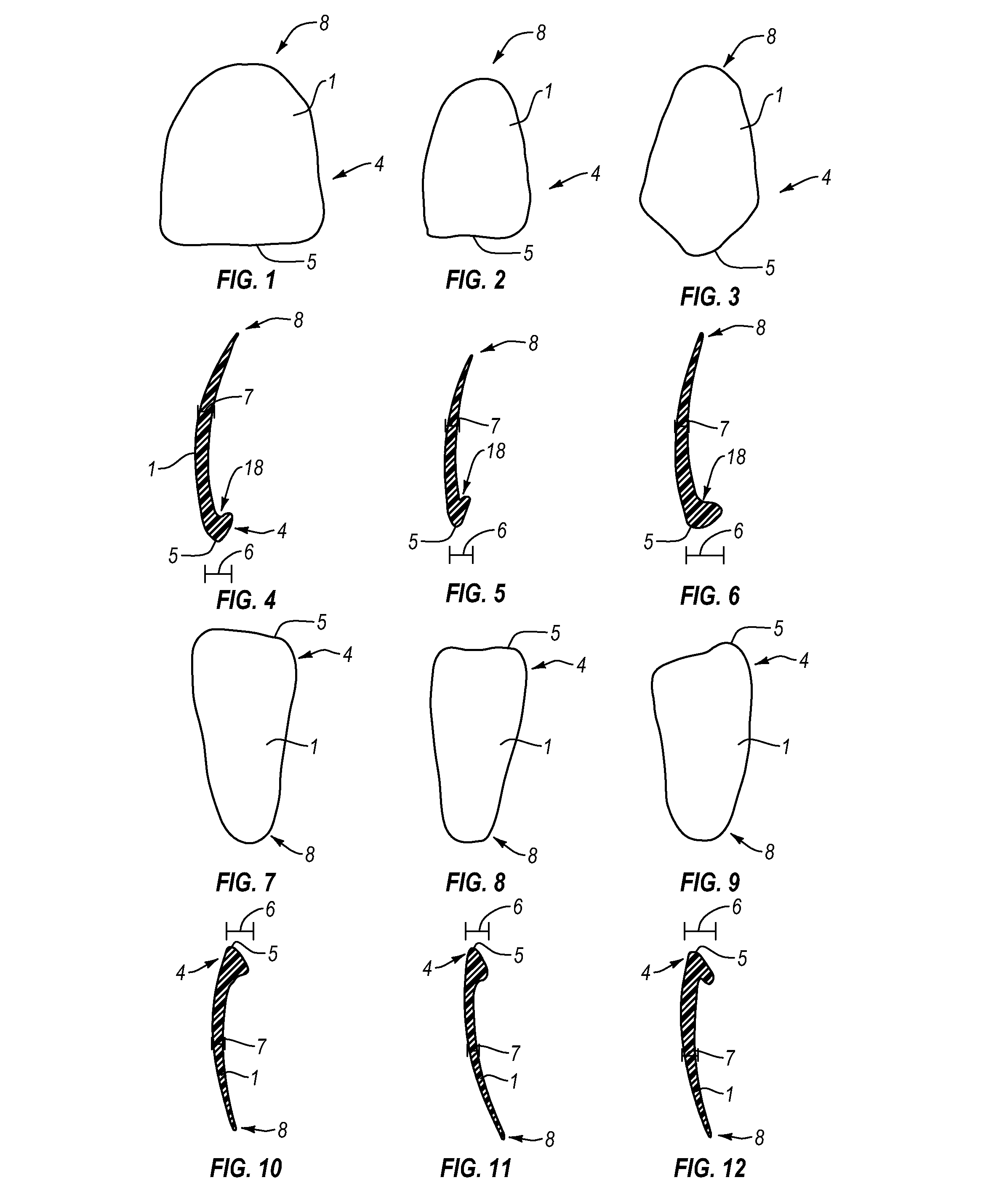

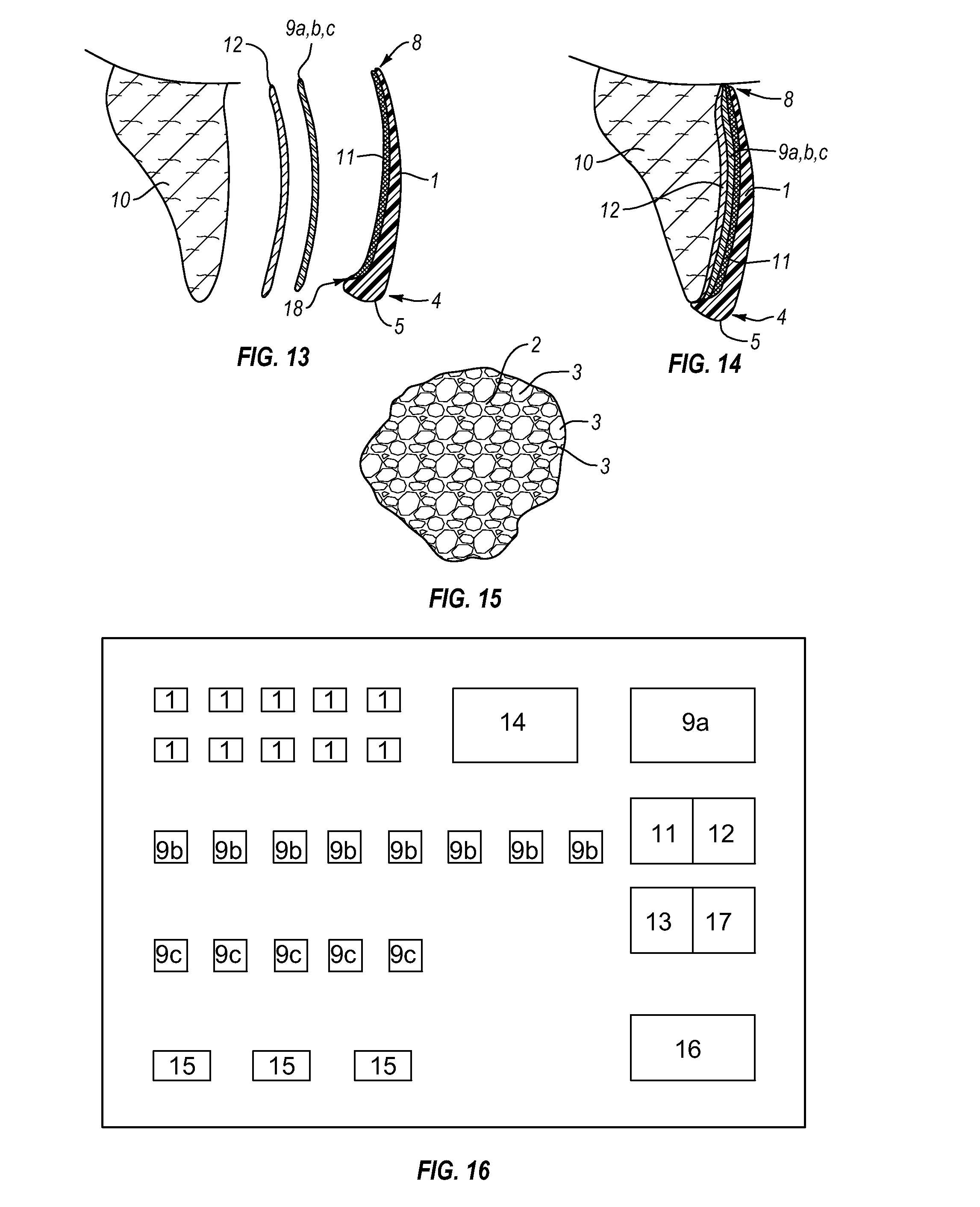

[0026]Disclosed herein are dental veneers made from composite materials comprising one or more types of organic binder and one or more types of solid particulate filler. An exterior surface of the dental veneer can be at least partially laser-treated to form a continuously hardened and / or glazed layer on the facial veneer surface. The composite from which the dental veneer is made may comprise at specific sections, preferably the surface of the dental veneer, a layer which consists essentially of only the glazed layer of the solid particles.

[0027]With regards to their shape, dental veneers of this type can be processed on site by the dentist using the common tools of his / her practice and thus be adjusted to the conditions given in the patient. This eliminates the necessity of producing the dental veneers in a lab.

[0028]Similar to prior veneers, the dental veneers according to the invention have solid bodies, which may be placed upon a tooth stump and / or tooth prepared in manners kno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com