Sound-based damage detection

a sound-based damage detection and sound technology, applied in the field of sound-based damage detection, to achieve the effect of saving cost and occupying spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

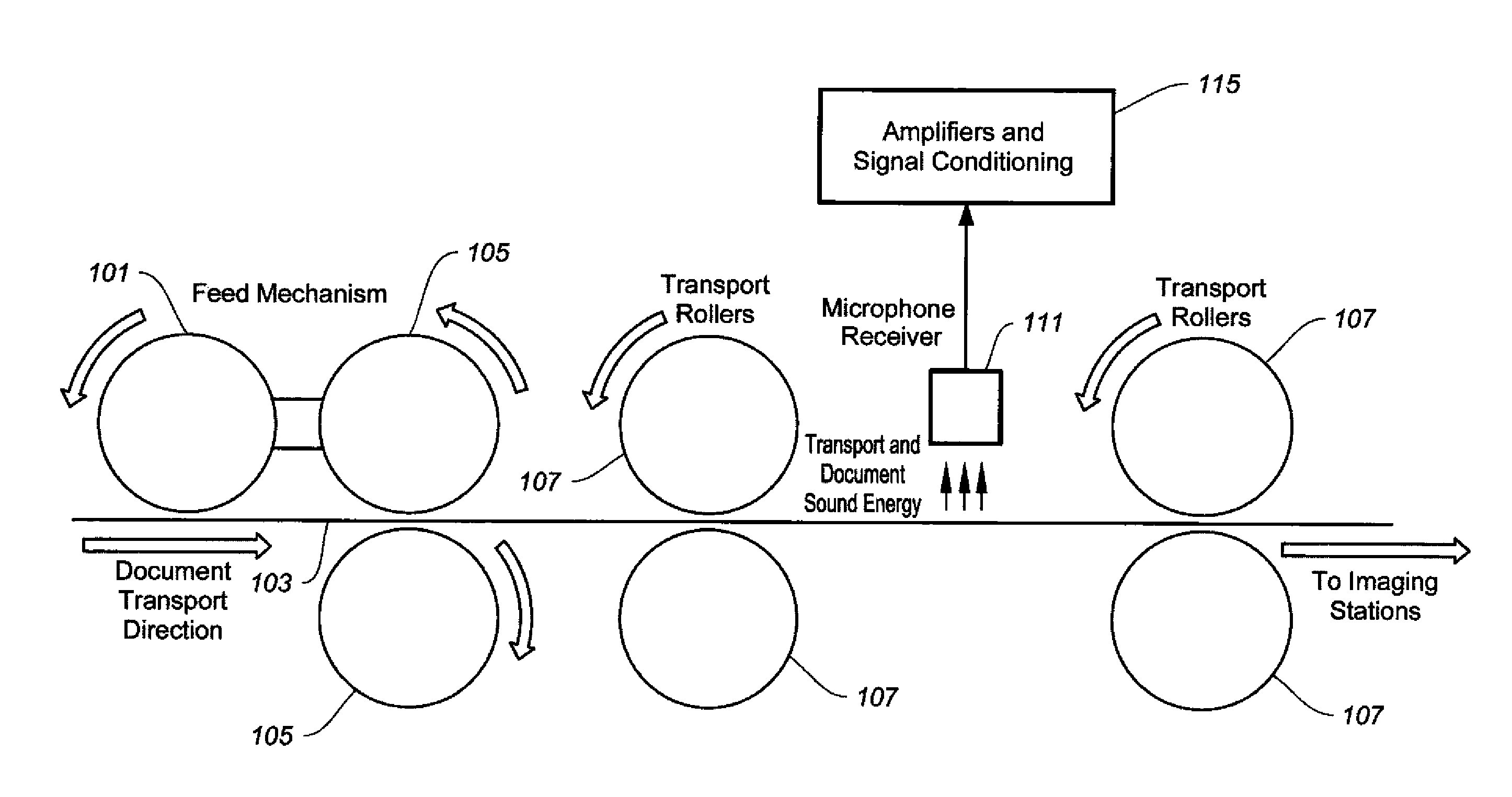

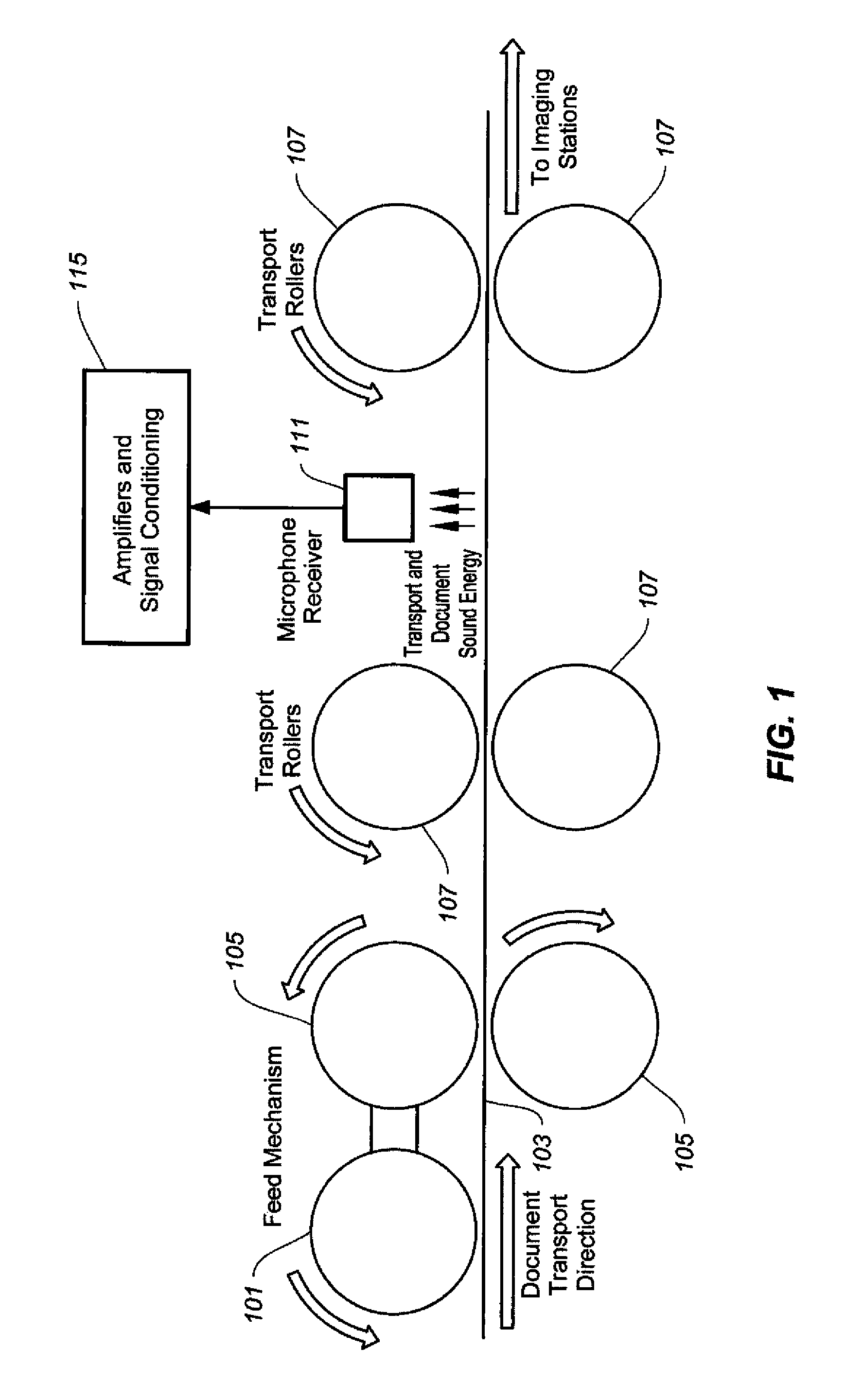

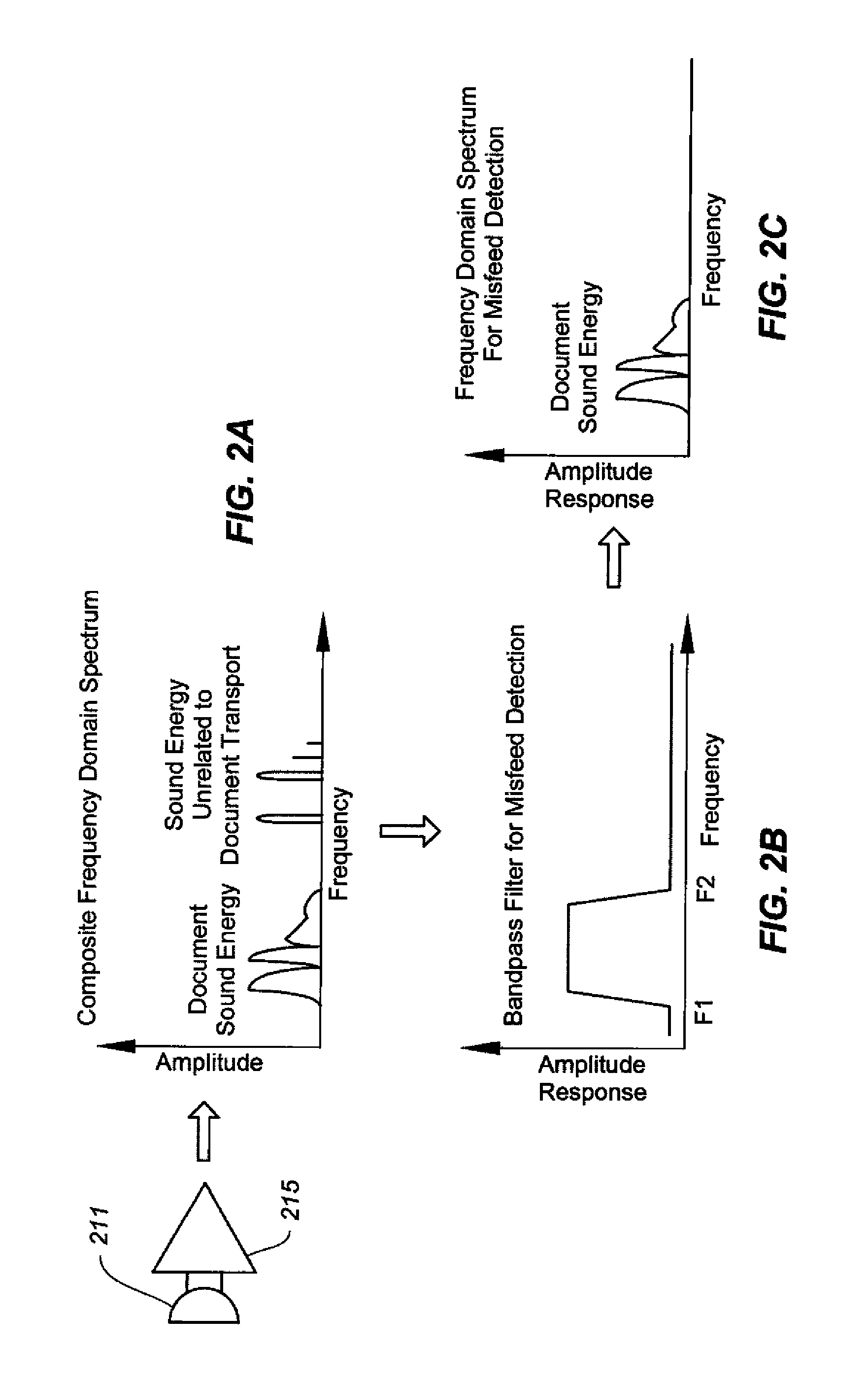

[0024]With reference to FIG. 1, document 103 is moved forward by urging roller 101 into the feed and separation nip created by contact of rollers 105. Not shown is a standard input tray holding a stack of documents wherein the urging roller is configured to separate the first one of the documents from the stack. One document at a time is sequentially pushed further into the transport rollers 107 by selective rotation of the feed mechanism rollers 105. Ultimately the document is transported to an imaging station or stations to be converted into a digital image. Sound energy created by the physical transport of the document through the transport is also converted to an electrical signal by receiver 111. This sound energy may be characteristic of normal, undamaged transport of the document including that of the scanner itself, or may contain sounds characteristic of a document undergoing damage as a result of the feed and / or transport process. The electrical signal from microphone 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com