Method and apparatus for determining gvf (gas volume fraction) for aerated fluids and liquids in flotation tanks, columns, drums, tubes, vats

a technology of aerated fluids and liquids, applied in the field of techniques, can solve the problems of reducing strength, prone to errors, and current methods for measuring entrained air can sometimes be slow and cumbersome, and achieve the effect of controlling the efficiency of the flotation process and enhancing the properties of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

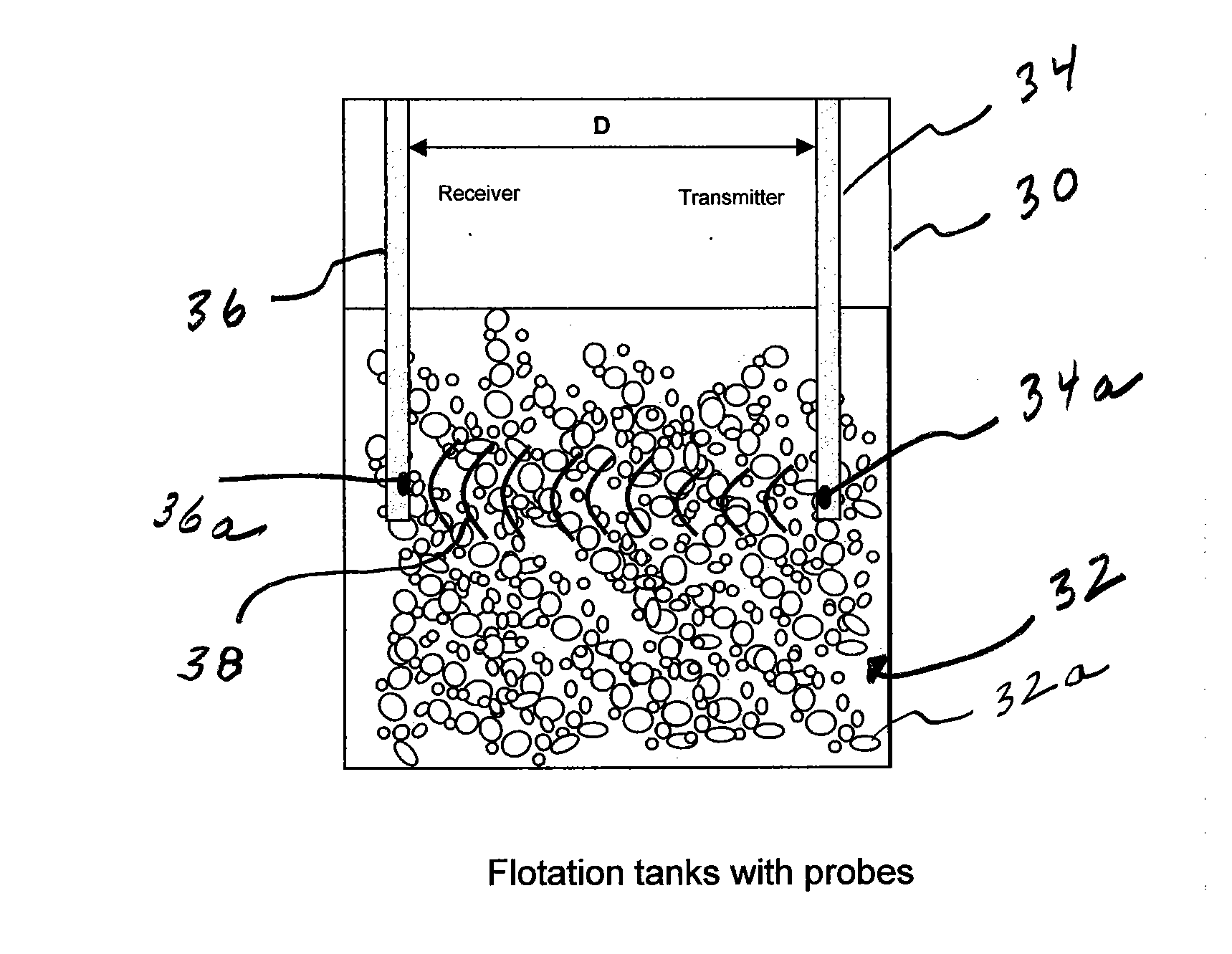

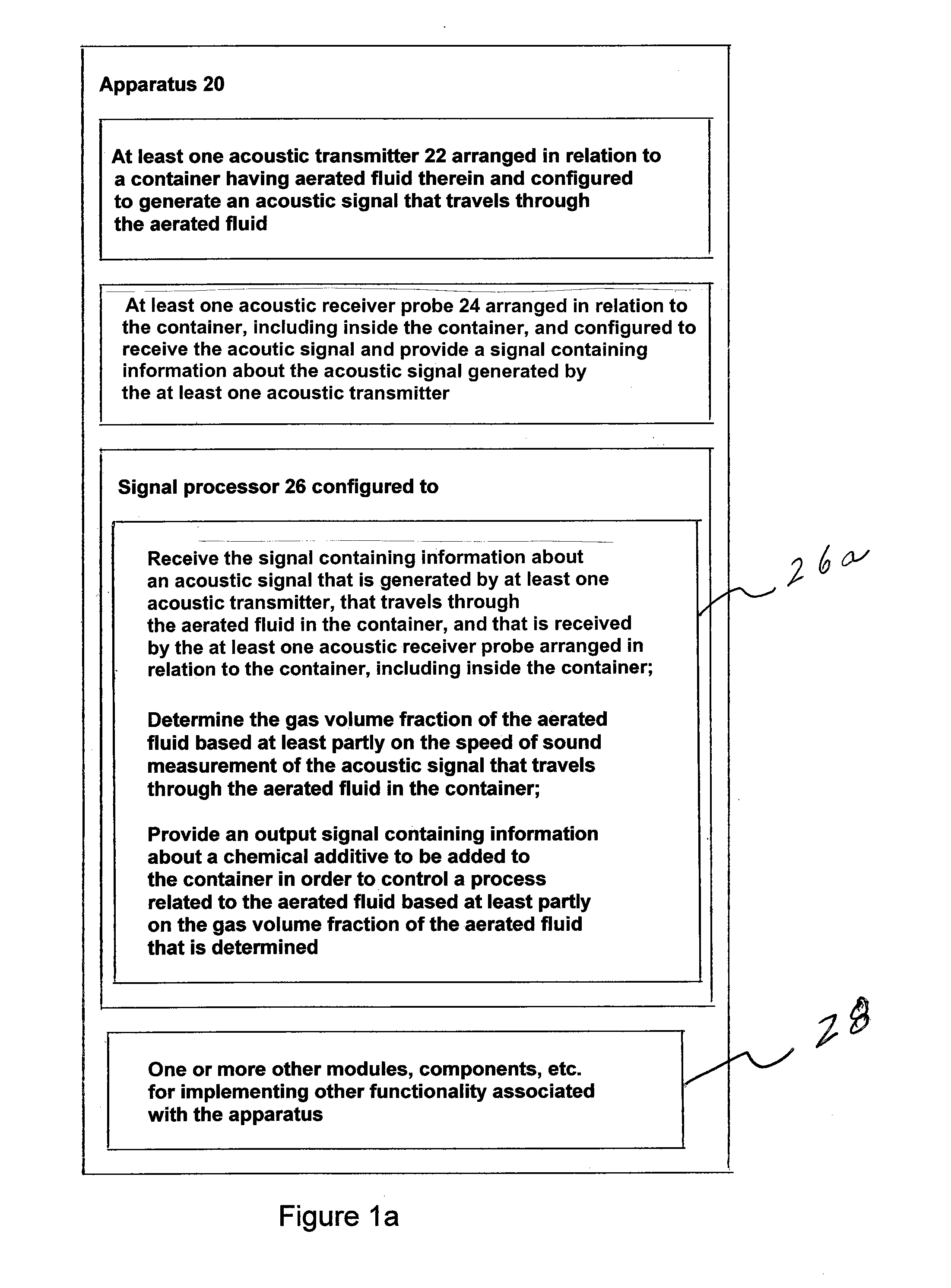

[0059]FIG. 1a shows apparatus generally indicated as 20 according to the present invention, which may include at least one acoustic transmitter 22, at least one acoustic receiver probe 24 and a signal processor 26.

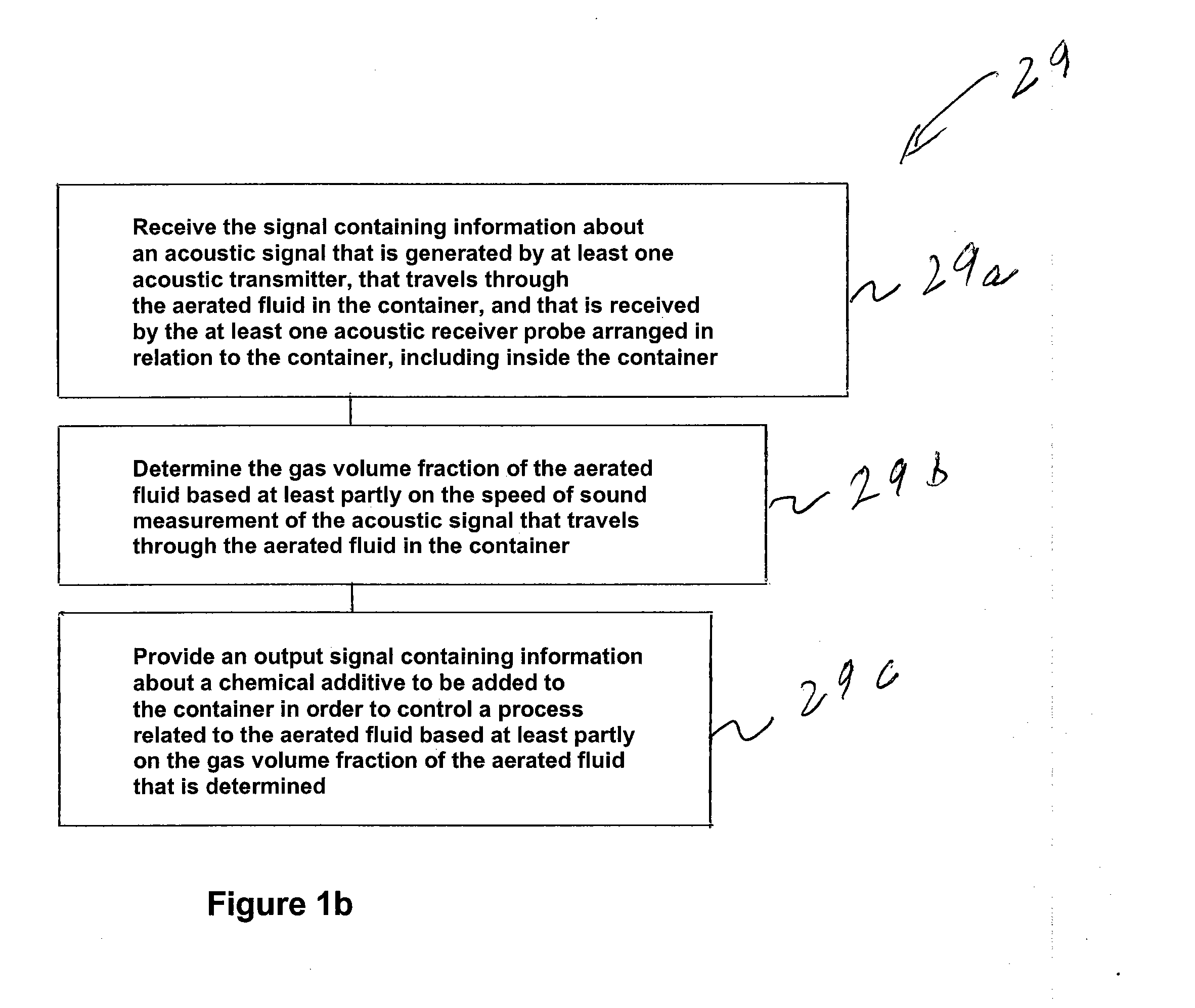

[0060]Consistent with the embodiments shown and described in detail below, the at least one acoustic transmitter 22 may be arranged in relation to a container having aerated fluid therein and configured to generate an acoustic signal that travels through the aerated fluid, and the at least one acoustic receiver may be arranged in relation to the container, including a receiver probe 24 arranged inside the container, and configured to receive the acoustic signal and provide a signal containing information about the acoustic signal generated by the at least one acoustic transmitter 22. In operation, the signal processor 26 is configured to receive the signal containing information about the acoustic signal that is generated by the at least one acoustic transmitter 22, that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com