Boiler for steam mop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

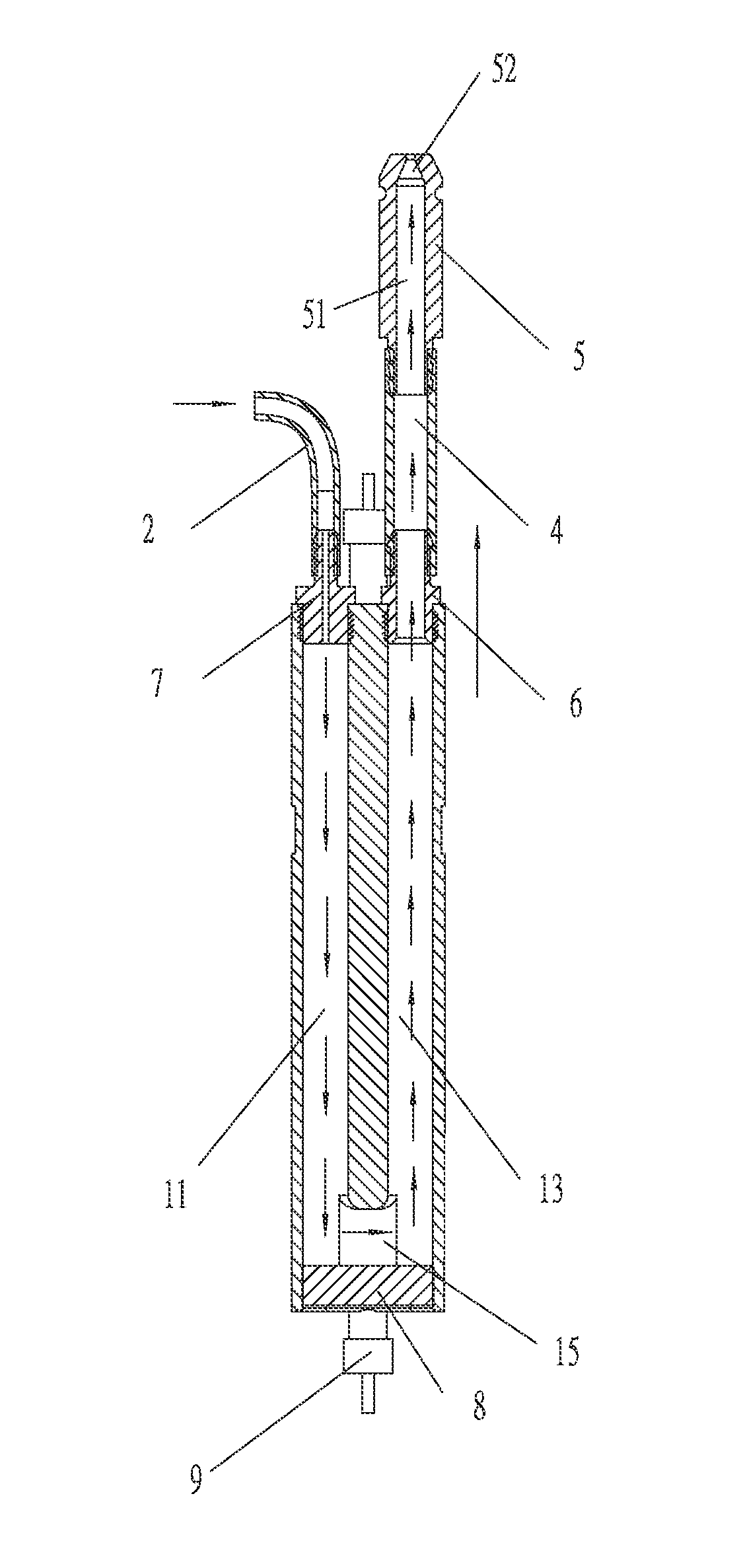

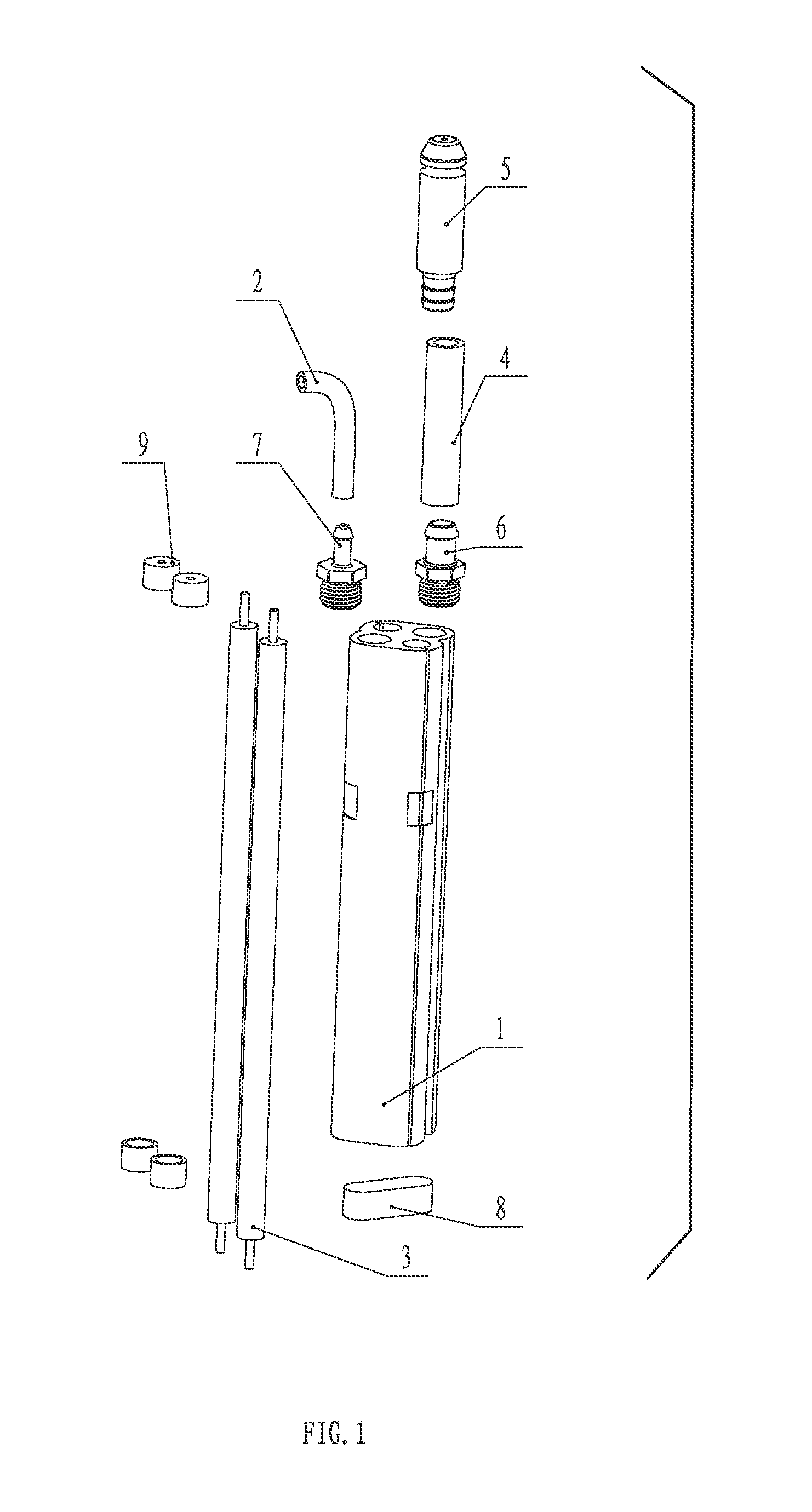

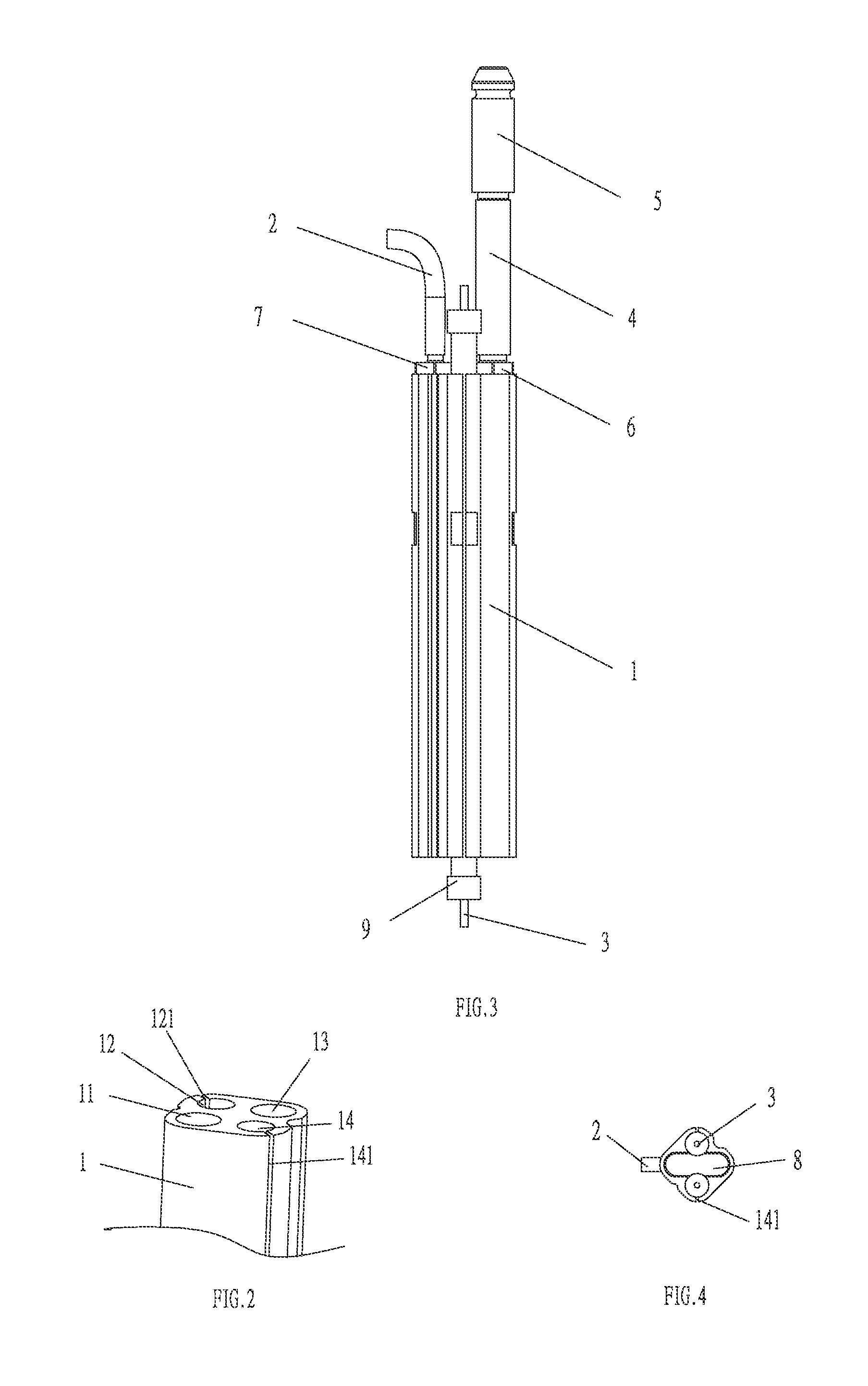

[0030]Refer to the FIG. 1 to the FIG. 6. The detailed embodiment of the present invention of a boiler for a steam mop includes a boiler 1, a water inlet pipe 2, a heating element 3, a steam pipe 4 and a steam nozzle 5.

[0031]The boiler 1 is cuboid shaped, and four holes are disposed inside along the length direction. Two holes 11 and 13 in the diagonal position are disposed as the liquid way, while another two holes 12 and 14 in another diagonal position are disposed as the way for the heating element 3. The holes 12 and 14 are separately disposed with a crack 121 and 141 on the wall for the material of expanding when heated and contracting when cooled. Two ends of the heating element 3 are separately extended out of the two ends of the boiler 1 and insulated by silica gel cap 9. A cover 8 is disposed in the lower of the boiler 1 to close the two holes 11 and 13. A lateral hole 15 is disposed inside the boiler 1 beside the cover 8 to connect the two holes 11 and 13. The holes 11, 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com