Method And System For Controlling And/Or Regulating The Treatment Of Heat-Sensitive Liquid Food Products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

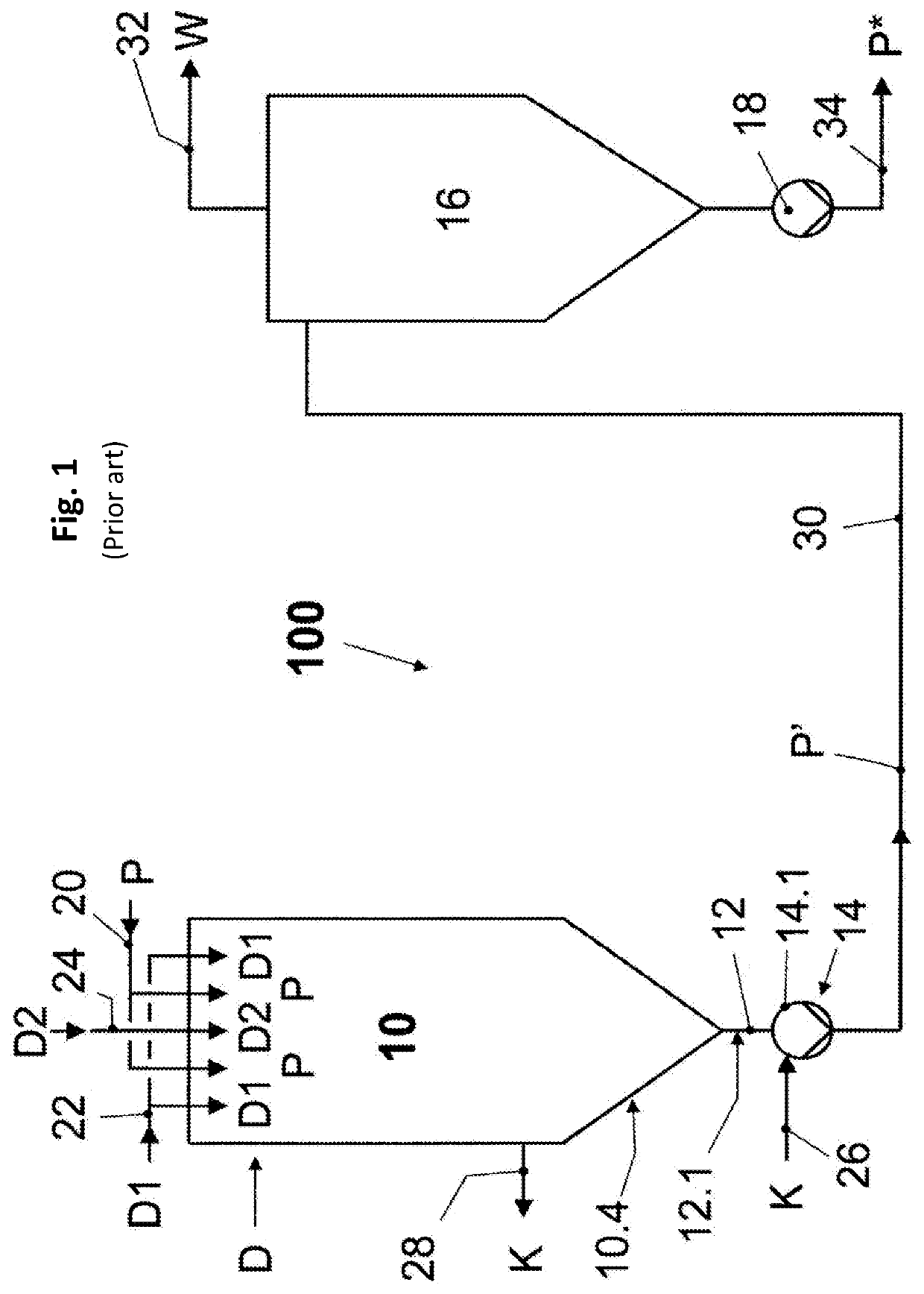

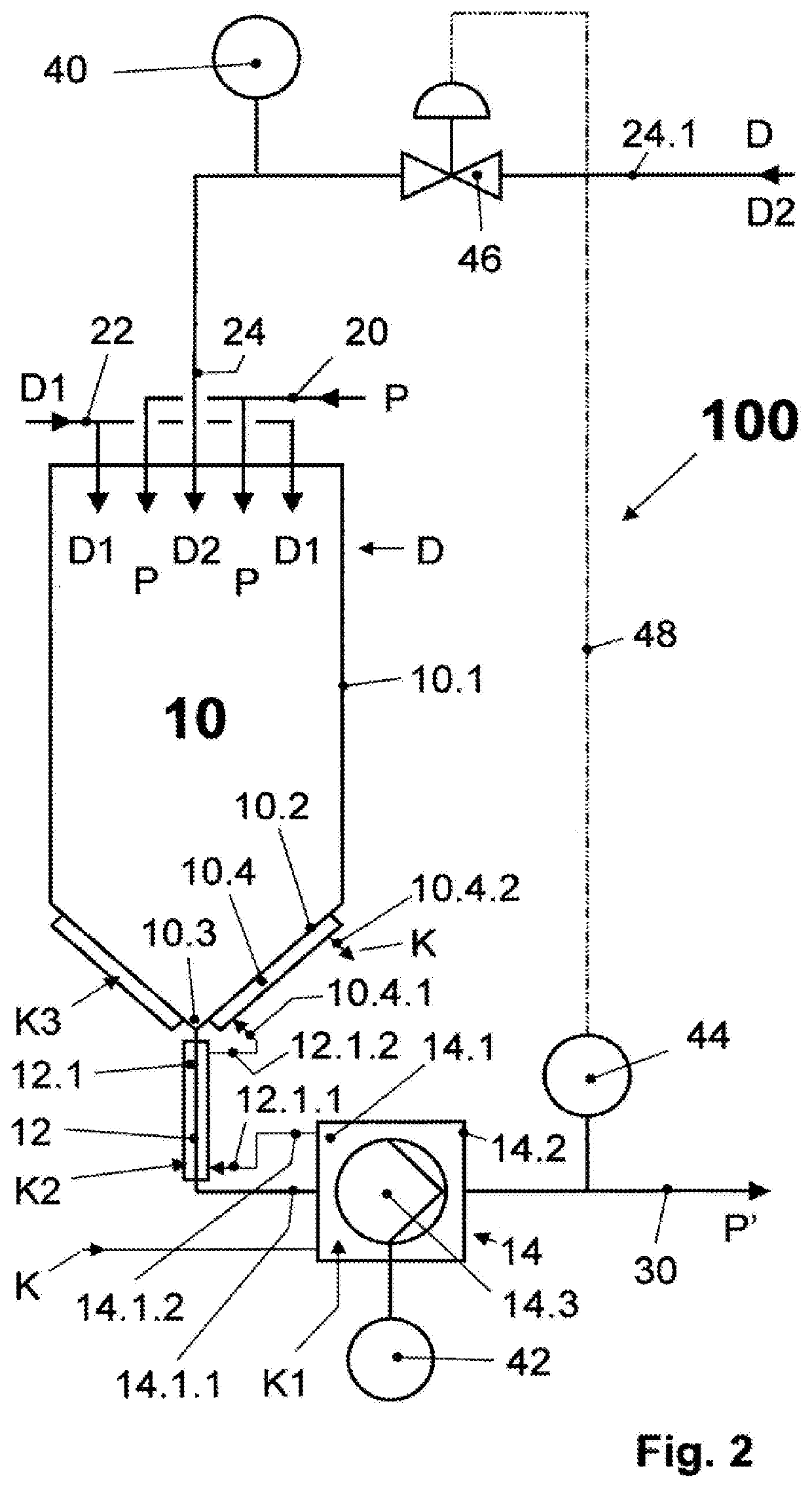

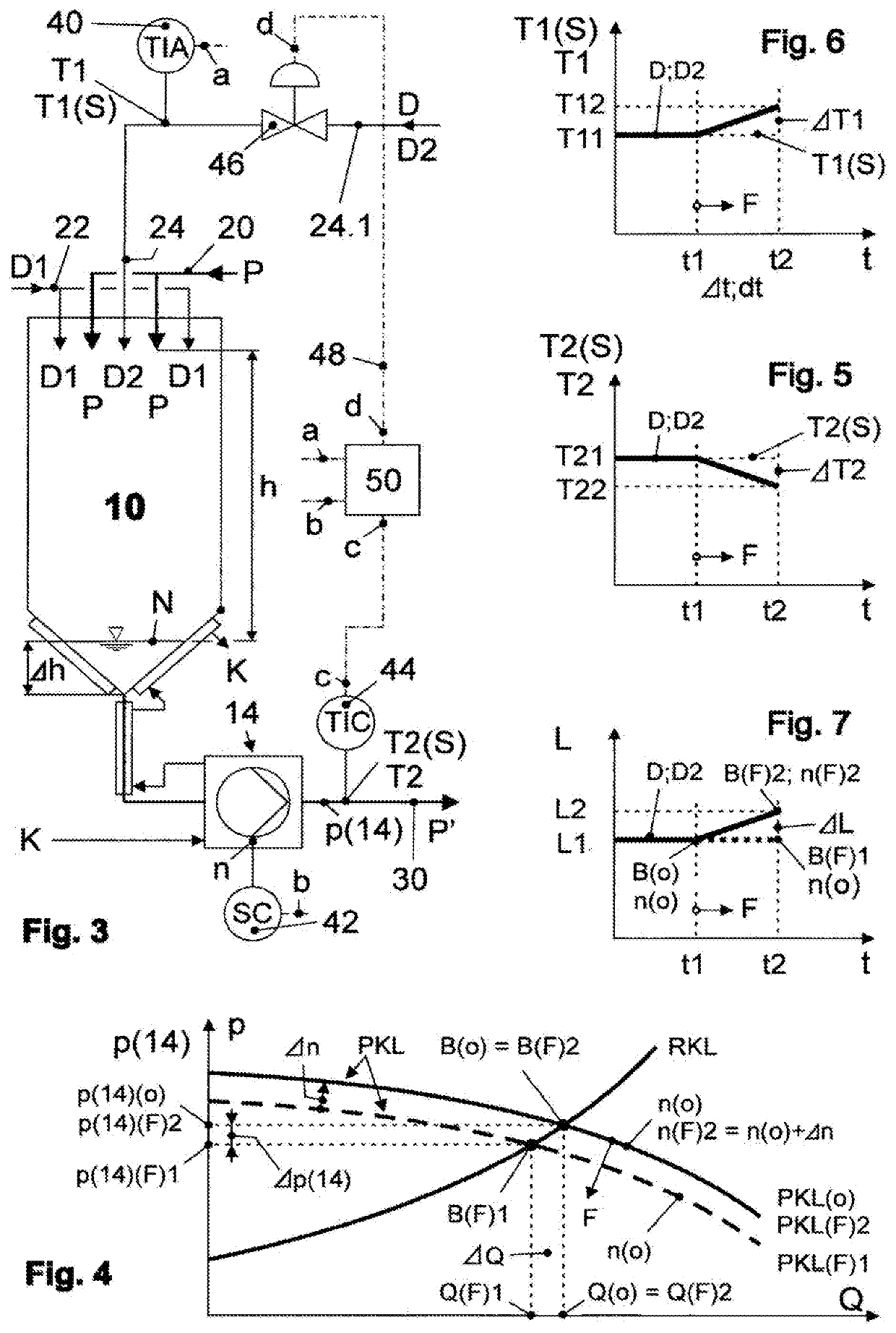

[0059]A system 100 known from the prior art according to FIG. 1 (such as WO 2016 / 012026 A1) contains an infuser container 10 as described for example in WO 2010 / 086082 A1 and that has a product inlet 20 in its headspace through which a liquid food product P that is to be heat-treated is supplied to this infuser container 10 centrally and annularly. The liquid food product P supplied in this manner is also supplied with steam D for direct heating through the headspace of the infuser container 10, namely a first steam D1 radially from the outside through an external steam inlet 22, and a second steam D2 radially from the inside through an internal steam inlet 24.

[0060]The infuser container 10 is bordered at its bottom tapering downward toward an outlet opening by a container-bottom-side coolant chamber 10.4. The outlet opening of the infuser container 10 is connected by a drainpipe 12 that is surrounded by a drainpipe-side coolant chamber 12.1 to a first delivery apparatus 14 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com