Wireless swnt sensor integrated with microfluidic system for various liquid sensing applications

a microfluidic system and sensor technology, applied in the field of wireless swnt sensor integrated with microfluidic system for various liquid sensing applications, can solve the problems of mass mortality of fish and seabirds, disease outbreaks, and high cost of procedures, and achieve the effects of reducing the number of swnt sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

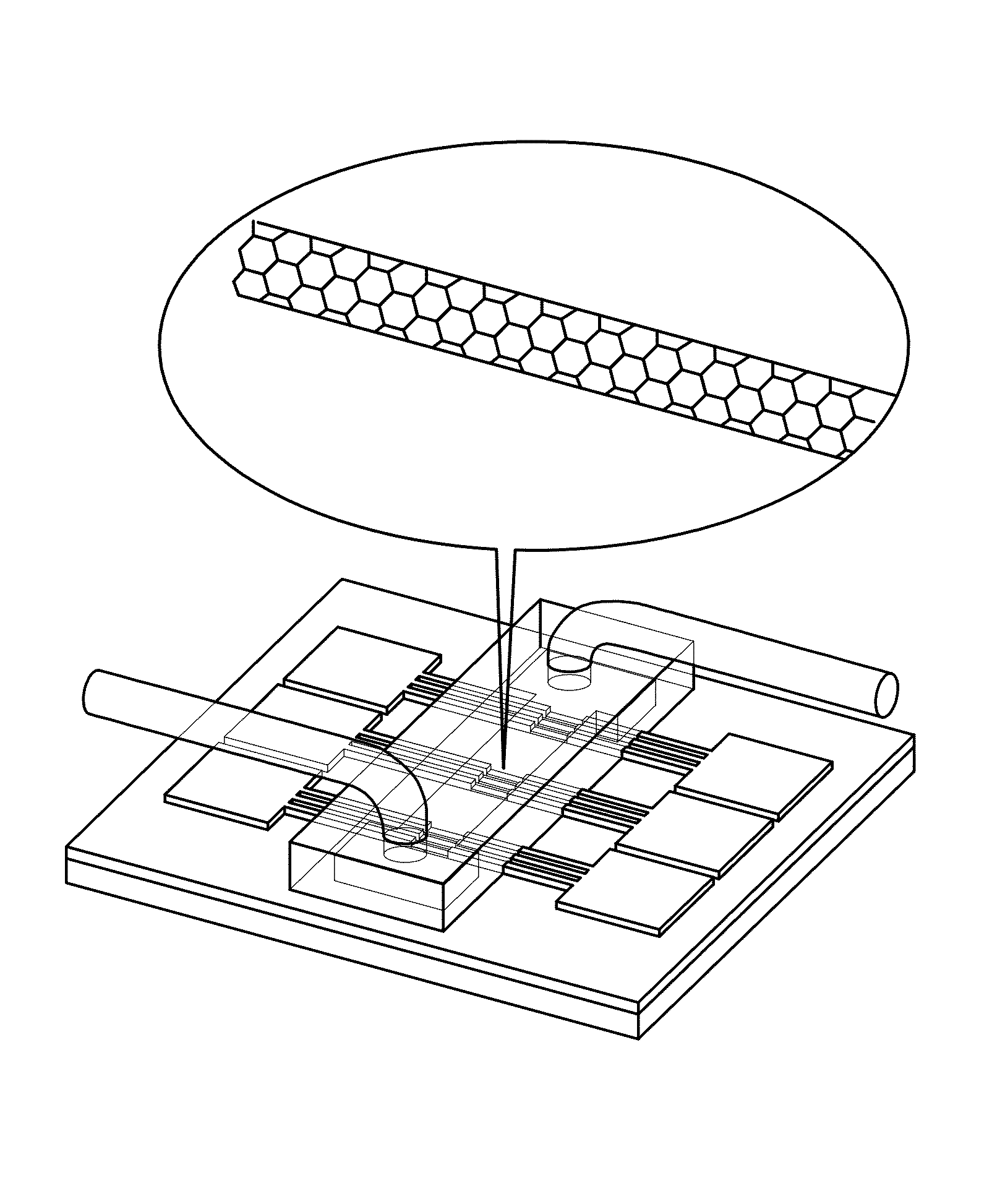

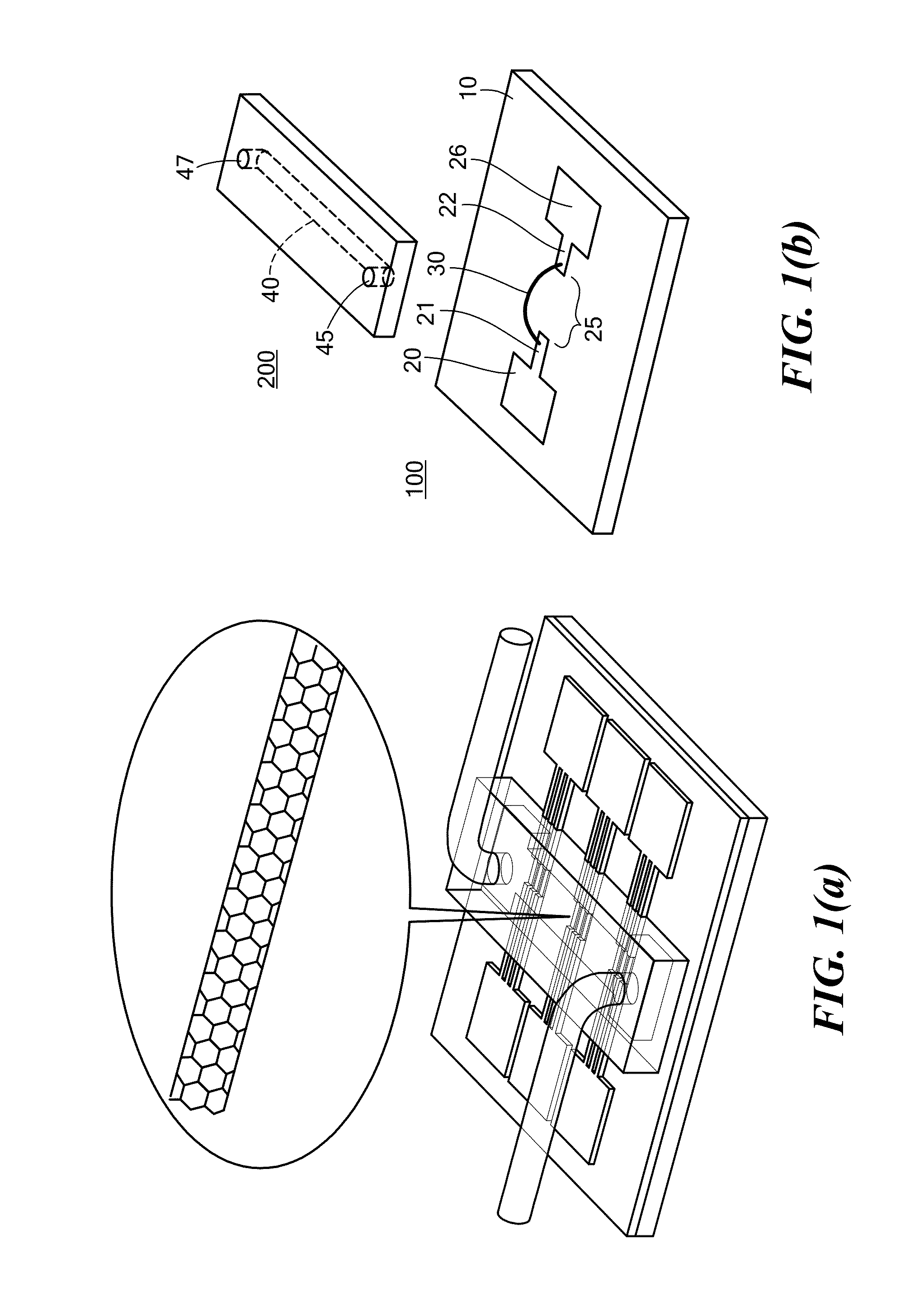

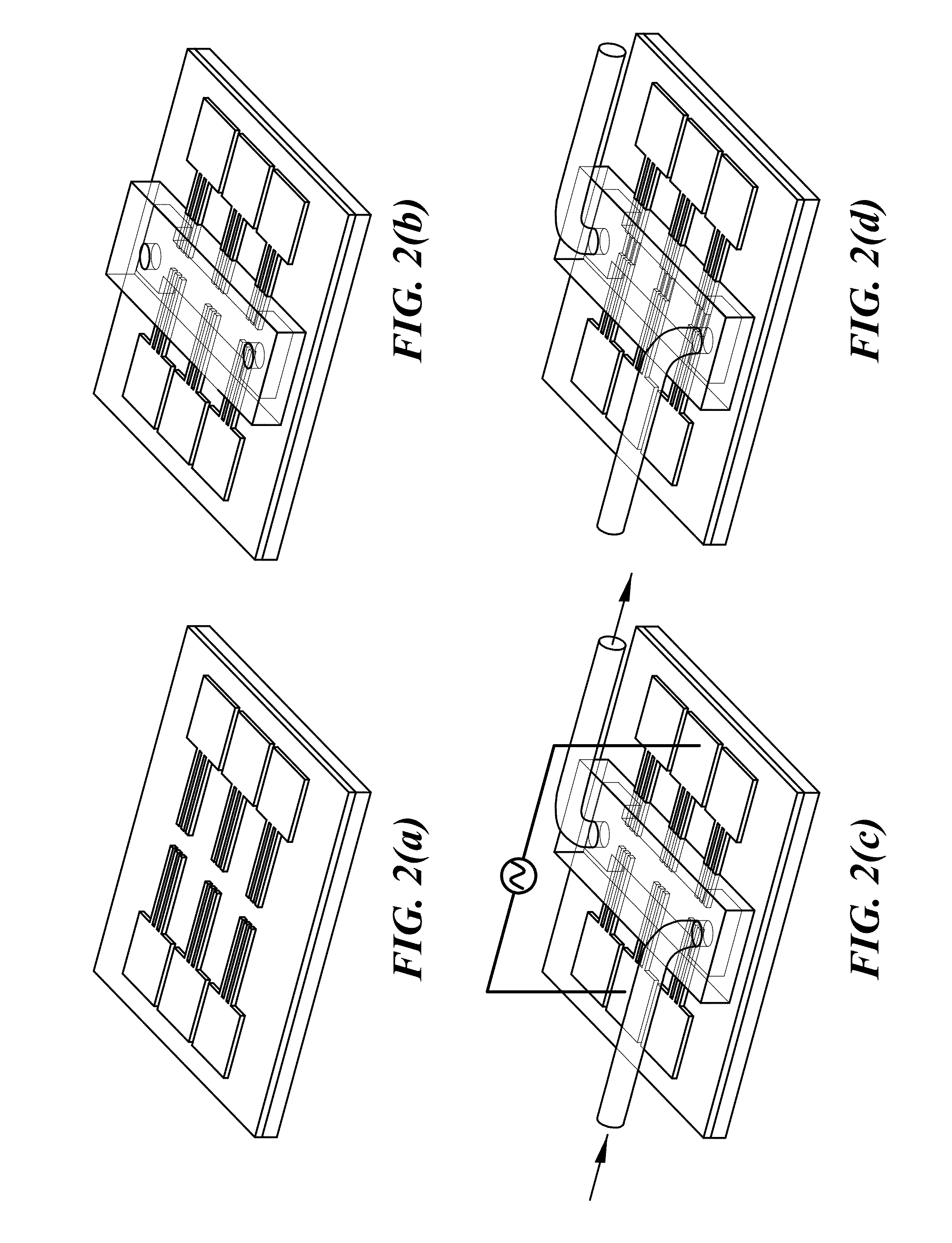

[0021]The inventors have developed methods for integrating sensors based on single-walled carbon nanotubes (SWNT) into a microfluidic system, and optionally outfitting the integrated device with data processing and wireless transmission capability. The sensors combine the sensitivity, specificity, and miniature size of SWNT-based nanosensors with the flexible fluid handling power of microfluidic “lab on a chip” analytical systems. The methods developed can be used to fabricate new sensor devices by constructing a microfluidic system using techniques that are compatible with the delicate nature of the SWNT sensor elements. The microfluidic mechanism enables the sensor devices to continuously and autonomously monitor liquid samples for the presence or absence and / or concentration of desired chemical agents. The addition of wireless data transmission extends the capability of the sensor devices to real time remote sensing operations, sensing in remote locations, and sensing of selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com