Amphibious pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

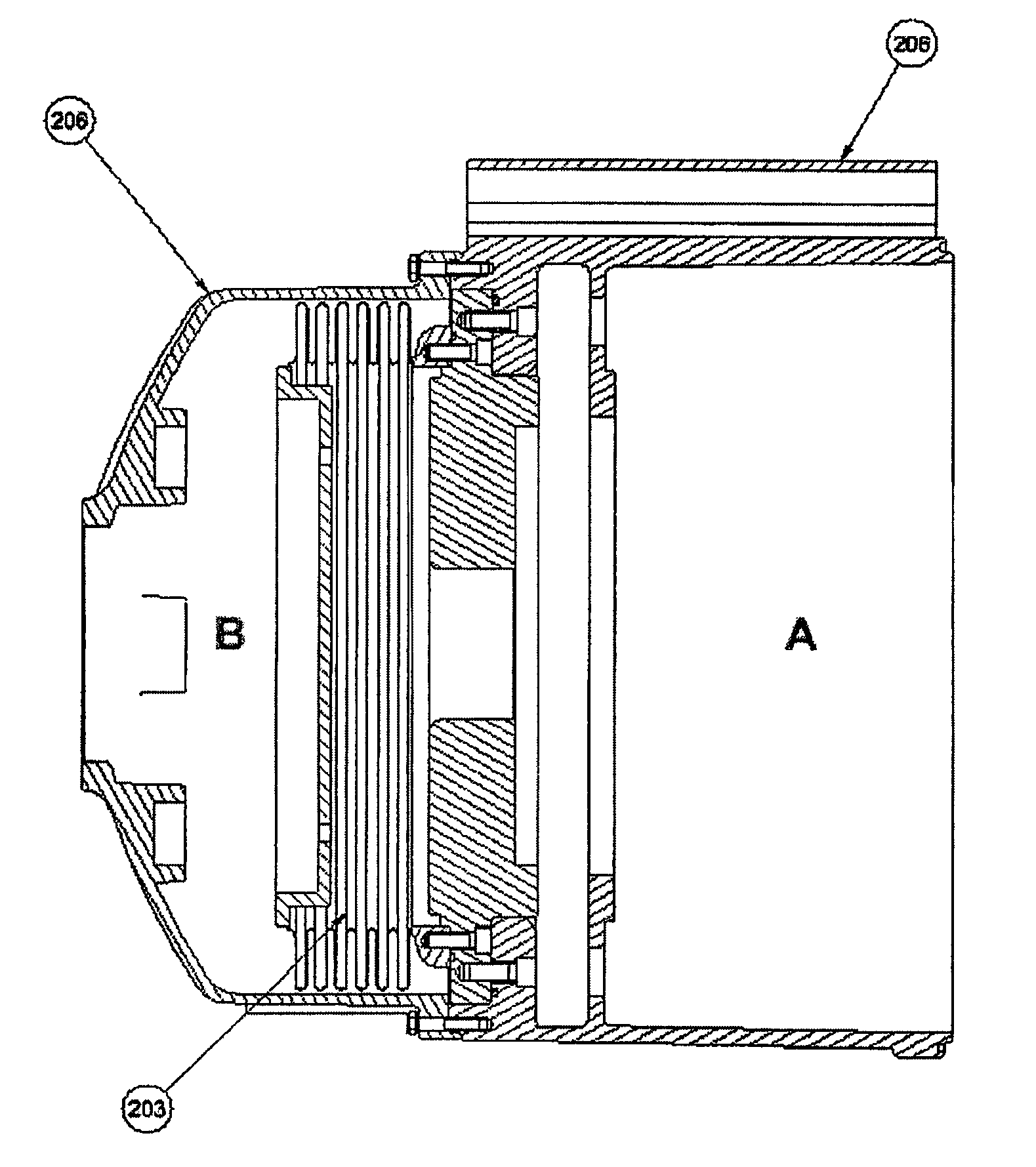

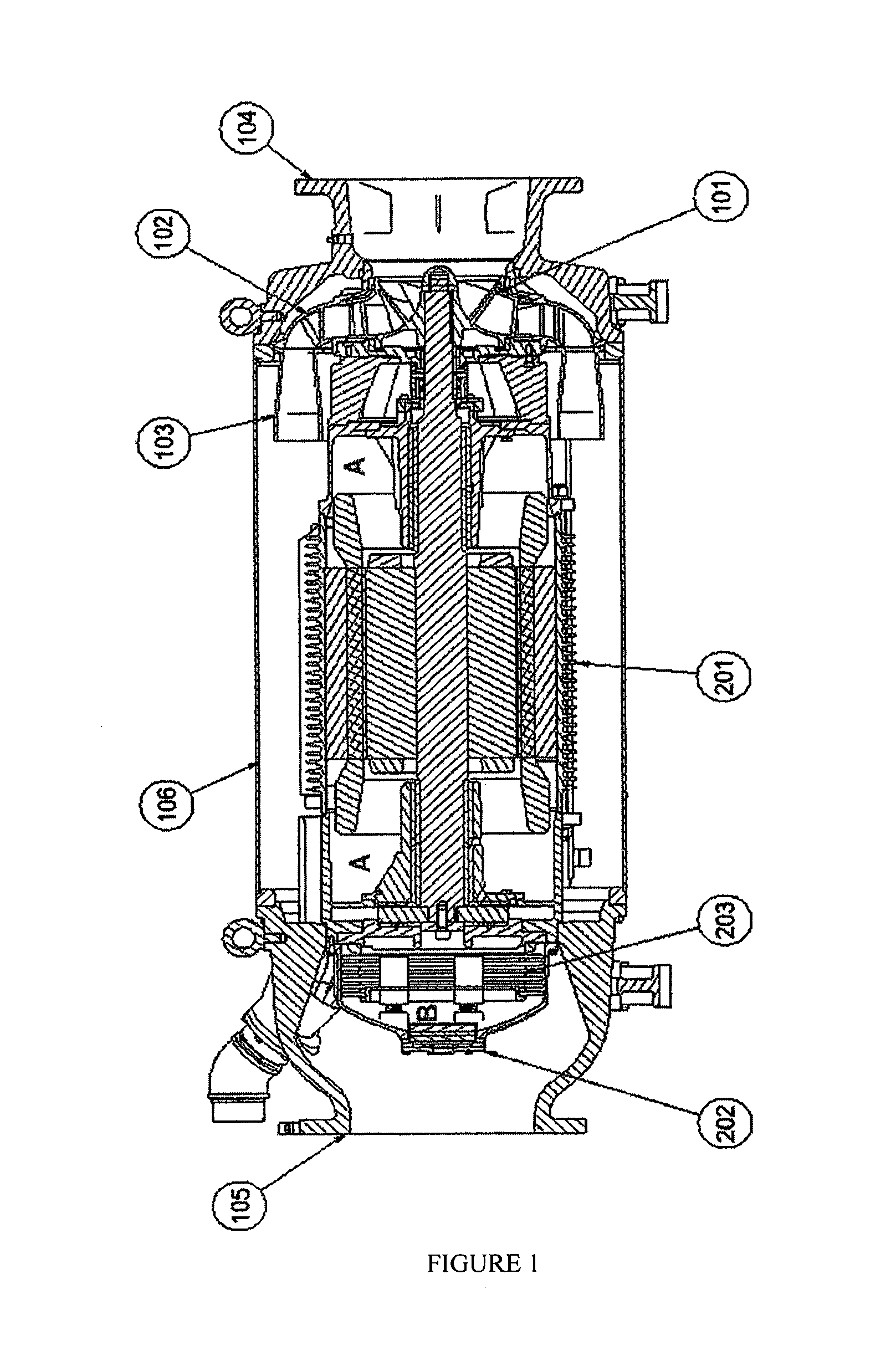

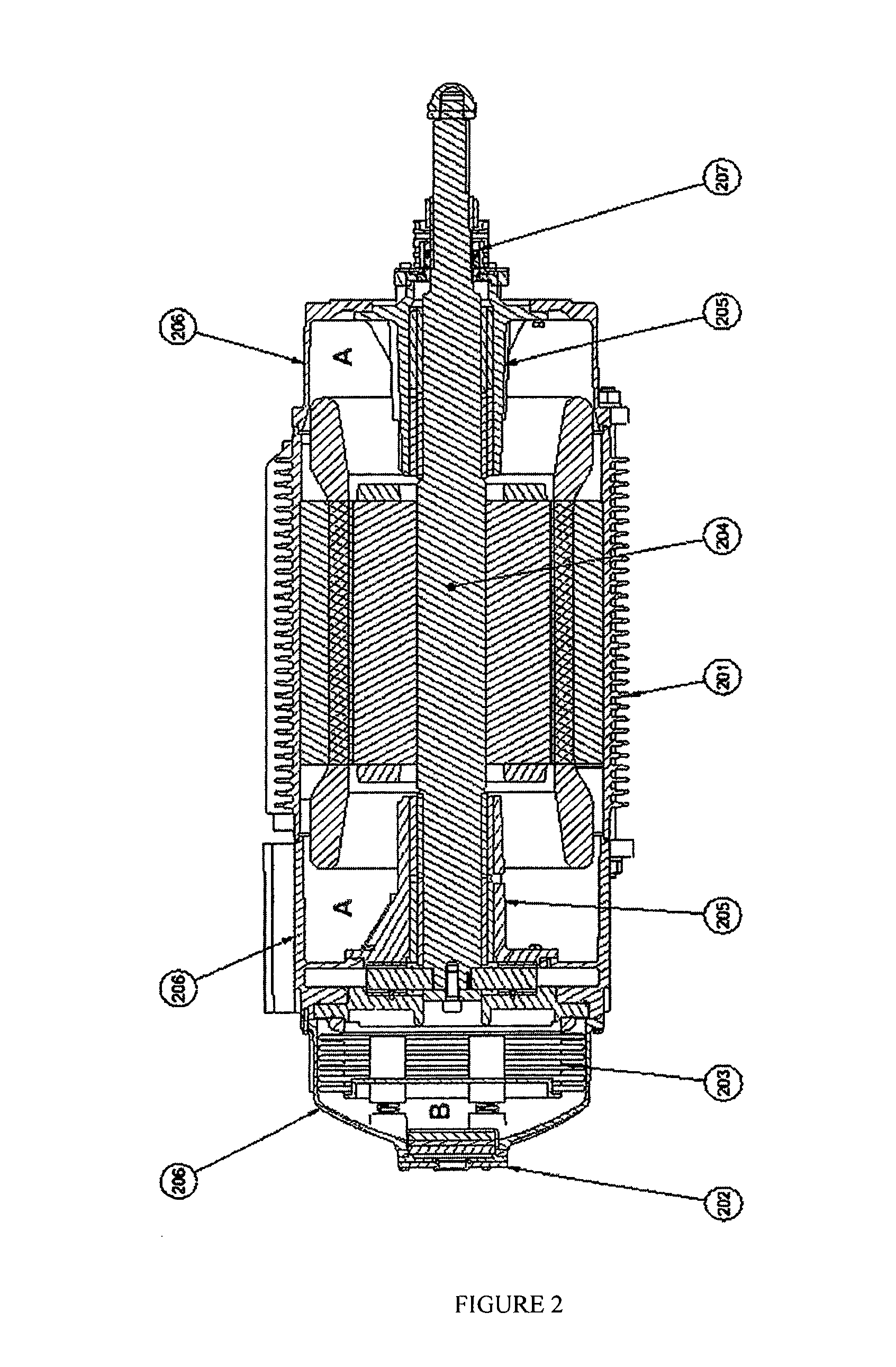

[0026]The pump proposed in this invention consists of an inlet outer housing (104) and an output (105), provided with flanges at their ends, and connected through a flow tube not shown in the figures. This set of parts is called external set and are known to the state of technology, inside this outer set a drive (20) and pump (10) system is mounted, called motor assembly. Between the motor assembly and the outer set an annular space is formed through which flows the pumping flux. This construction is typical, of the state of technology.

[0027]The flanges are elements that link two components of a piping system, or piping to pump, allowing to be dismantled without destructive operations. The flanges are usually mounted in pairs and joined by screws, maintained the contact surface between two flanges under compression force in order to seal the connection. These elements normally used in the state of technology.

[0028]Internally, the pump consists of the pumping assembly (10) and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com