Awning comprising a vibration-damped drive

a technology of vibration-damping drive and awning, which is applied in the direction of sunshades, buildings, constructions, etc., can solve the problems of increasing the complexity of the system, increasing the cost of installation, so as to prevent excessive compression, improve the wear resistance of the vibration-damping device according to the invention, and avoid permanent loss of foam structure and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

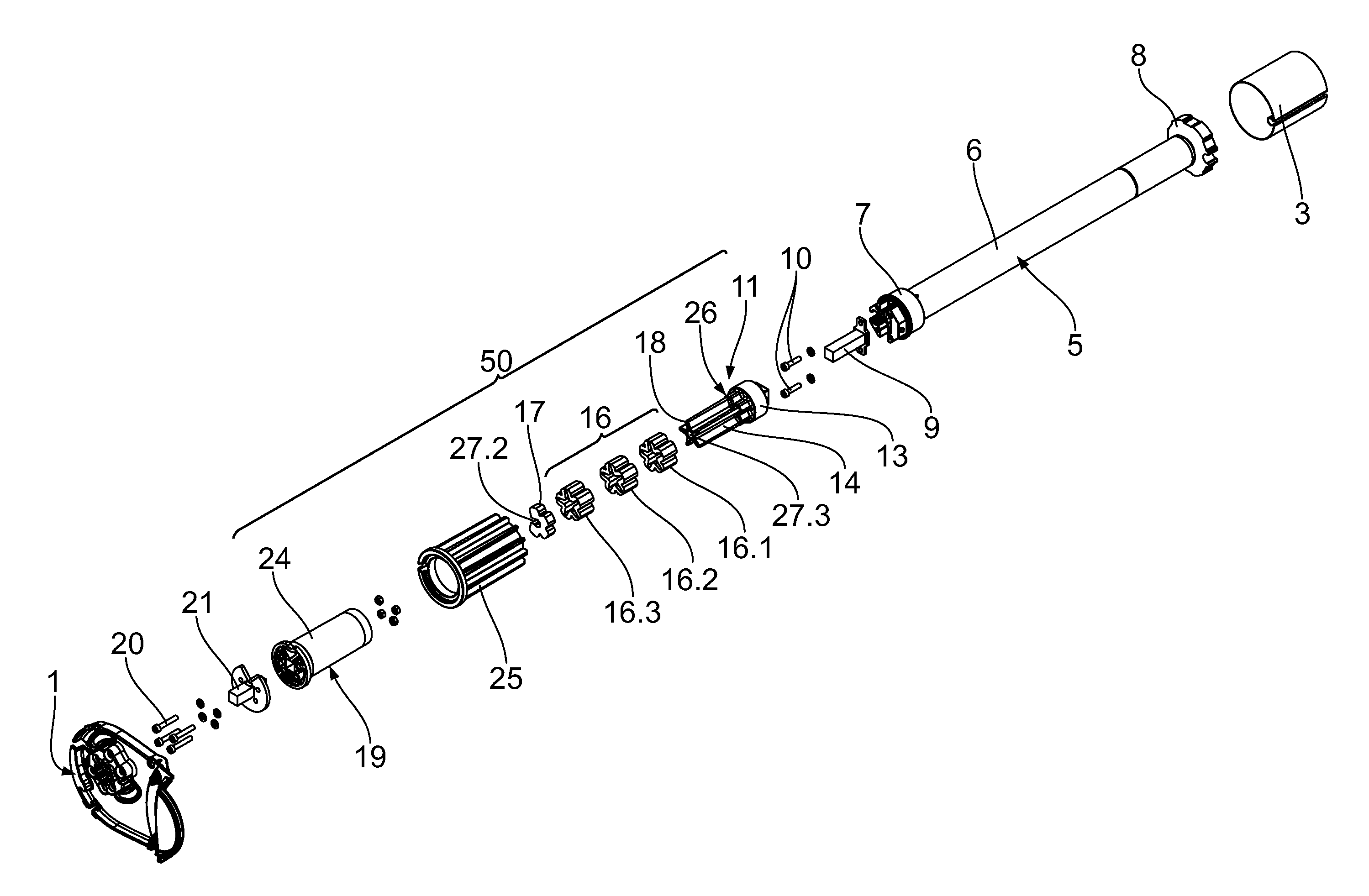

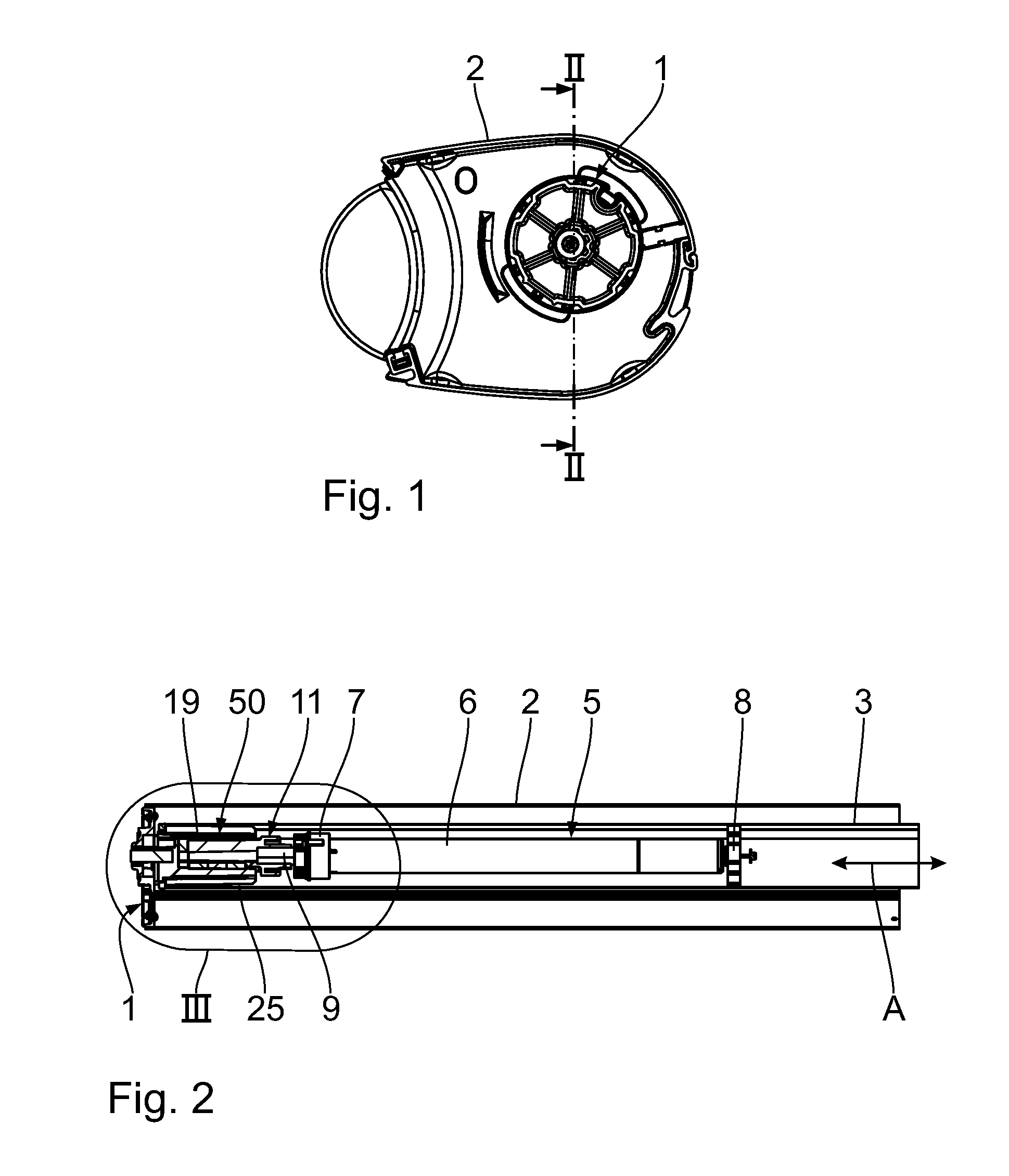

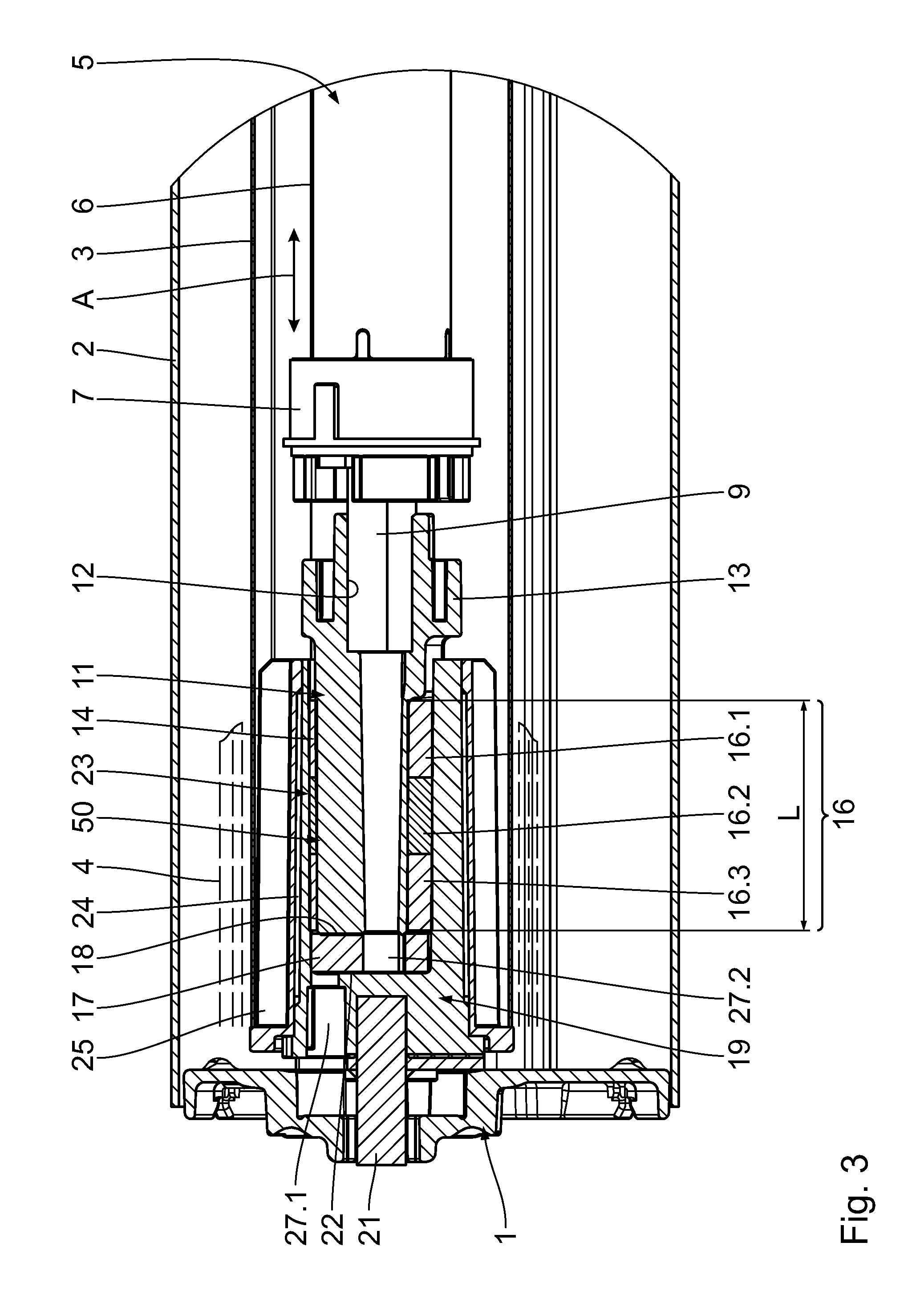

[0033]With reference to FIGS. 1 to 4, the partially shown awning comprises two holding brackets 1 arranged on a base member not shown in greater detail, of which only one is shown in the drawings. For clarity, the mentioned base member by means of which the awning is secured to a housing wall or the like is omitted from the Figures as well.

[0034]The awning is a housing awning in which the components are arranged in a housing 2. These components essentially include the tube-shaped fabric shaft 3 which is mounted between the holding bracket 1 shown in the Figures and the second holding bracket; the fabric shaft 3 is mounted for rotation on the holding brackets 1 in a way that is set out below. An awning fabric 4 which is shown dashed in FIG. 3 can be wound in and out by means of the fabric shaft 3. The extending and retracting movement of the awning fabric 4 is of no importance in the present invention; it can for example be performed using joint arms and a drop-out bar together with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com