Light-emitting diode packaging structure of low angular correlated color temperature deviation

a technology of light-emitting diodes and packaging structures, applied in the direction of basic electric elements, electrical apparatus, semiconductor devices, etc., can solve the problems of low optical performance, and achieve the effect of reducing the angular correlated color temperature deviation and long optical path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

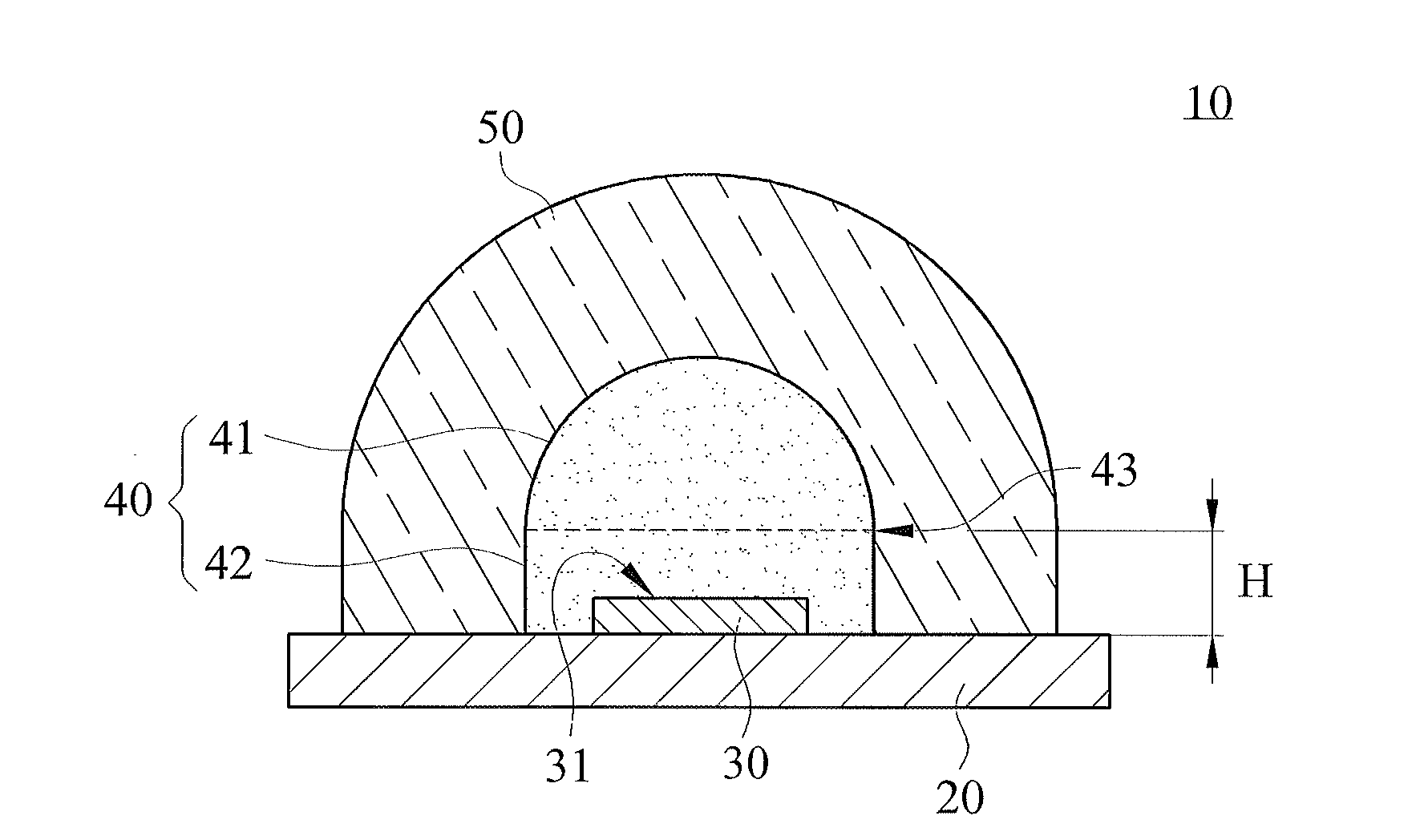

[0022]Referring to FIG. 4 and FIG. 5, there are shown a perspective view and a cross-sectional view of a light-emitting diode (LED) packaging structure 10 of low angular correlated color temperature deviation according to an embodiment of the present invention, respectively. The LED packaging structure 10 comprises a substrate 20, an LED chip 30, a phosphor body 40, and a transparent lens 50.

[0023]The substrate 20 is a circuit substrate, such as an aluminum circuit substrate, a ceramic circuit substrate, or a PCB circuit substrate. In general, the substrate 20 in wide use is an aluminum circuit substrate or a PCB circuit substrate.

[0024]The LED chip 30 has an upper surface 31. The LED chip 30 is mounted on the substrate 20 by a die mounting process. Afterward, in a wire bonding process the LED chip 30 is electrically connected to a circuit structure on the substrate 20 by metal wires (not shown).

[0025]The phosphor body 40 is a gel mixture of phosphor materials and silicone gel. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com